Česká zbrojovka Uherský Brod: an 80 years-old young company

By Paolo Valpolini & Joseph Roukoz

In the mid-1930s the tension in Europe was mounting. Having one of the major national armaments factories at a few tens of kilometers from the German border, in Strakonice, was a concern for Czechoslovack authorities. In 1936 it was thus decided to move the production further inland, a green area having been identified in Uherský Brod, a small town 50 km west of Brno. In slightly more than four months the new facility was built, production being started in November 1936. To lure air reconnaissance many of the buildings had roofs similar to those of the nearby village, and this helped in avoiding bombardments by Allied formations when, following the invasion, the plant started to produce weapons for Germany.

Initially the production was mostly devoted to aircraft machine guns, such as the vz. 30 and the MG17, and it was only after World War II that it shifted towards small arms, CZ 236 and CZ 800 line air rifles among them. Until then a branch of the Strakonice plant, in 1950 the Uherský Brod facility became independent and changed name a number of times, while production remained concentrated on firearms, such as submachine guns, semi-automatic rifles and pistols. In 1961 the Škorpion vz. 61 was developed, a name still well known, while in 1975 the CZ 75 marked a quantum jump in terms of handgun design. The company historical collection is located in the same area of the CEO office, and hosts all the aforementioned weapons as well as other, the first production CZ 75, the 00001, as well as the one million pistol, plus the 002 prototype being on show.

In 1992 the factory became Česká zbrojovka a.s., Uherský Brod, which remains its current name. In the time diversification led to the production of mechanical parts for the aviation and the automotive industry, which still represent 20% of the turnover, the core business of CZUB remaining however small calibre firerarms. Considerable yearly investments have transformed the plant in one of the most modern arms manufacturing plants, quality being the utmost aim of the company management.

EDR Magazine was invited to visit the Uherský Brod facility. Following a short introductory briefing, at the very start of the company tour we met a group of young people; they were the pupils of the internal school for mechanical that allows CZUB to form its manpower since school age. Funded by the Czech State with financial contribution from CZUB, many of those kids will in the near future become part of the company “family”: according to our hosts it is common to find whole family groups working at the plant.

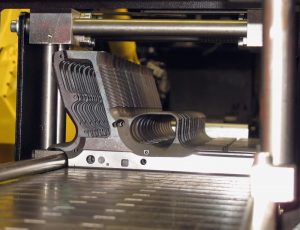

Most machines are fully automatic, robots having replaced manual work in most areas. This said, the CZUB plant still hosts some 1,800 workers. Slides are machined while frames are cast, nearly all work being done inside the company. When subcontractors are needed, CZUB tends to work with Czech ones, the company also using Czech steel. The decision to go for all national subcontractors, instead of using cheaper solutions, was made both for quality and flexibility purposes, the closeness with them allowing quick modification to be done; this is true both from the technical standpoint, should a minor changing be needed, as well as for production. An urgent order for 150 pistols to be delivered within 20 days was completed in only six days exploiting the CZUB plant production flexibility but also that of subcontractors. The Uherský Brod plant produces an average of 1,000 weapons a day, a P-07 pistol, which frame comes from a subcontractor, being manufactured in less than one day. Lost wax casting is used for frames and all precision mechanical parts, barrel production being currently the bottle neck in production: three cold hammering forging machines are working 24/7, a fourth being currently being acquired. Those machines need to be always supervised, which is not true for other ones. Barrels for assault rifles are the only to be chrome plated, another operation carried out internally, which gives them a guaranteed life of 20,000 rounds. Current chrome plating is much less thick than that used for example in the vz. 58 assault rifle, however thanks to new technologies and the optimisation of the whole production process the same result is guaranteed in terms of barrel life.

Military and law enforcement have become again a major part of the CZUB business in the last decade, with the advent of a new series of products, such as the Scorpion EVO, the P-07 and P-09 handguns, and last but not least the CZ 805 BREN, which took the name from the Czech LMG designed for the British on the eve of World War II, and which has since been adopted by the Czech Army and some other international customers. Not only the visit allowed EDR Magazine to tour the facility; on day two of the visit we were hosted at the Bzenec shooting range, owned by the Czech military, to fire test the military, law enforcement and civilian production of CZUB, among which the latest product of the company, the BREN 2, an improved version of the Czech Army service rifle, which will soon enter service with the Army Quick Reaction Brigade, initial deliveries being scheduled before year end, and a version of which is currently proposed to Pakistan for a lucrative contract. CZUB has definitely become one of the world major players in the small arms field.

Investments and innovation do not cease at Uherský Brod, in order to ensure that company products remain at the top of the international production.

The Zbrojovka Brno history

In 2015 Arthur Nutbey, a Dutchman whose passion for Zetor tractors led to the writing of a book about those Czechoslovak equipment. Zetor tractors were built at Zbrojovka Brno, an Austro-Hungarian arsenal that became one of the world’s most successful arms manufacturers between the two World Wars. Involved in the manufacturing of arms under the Brno Arms brand. Today Zbrojovka Brno s.r.o, the successor of the former arms producer, is a subsidiary of CZ. Following his book “Zetor Tractors” Arthur Nutbey decided to write a new book on the history and the diversified production of Zbrojovka Brno from the early 1900 to 2003, when the company was forced into bankruptcy. Although a history of diversification, a great part of Arthur Nutbey’s book is dedicated to the company small arms production. For more information visit www.arthurnutbey.com.

In 2015 Arthur Nutbey, a Dutchman whose passion for Zetor tractors led to the writing of a book about those Czechoslovak equipment. Zetor tractors were built at Zbrojovka Brno, an Austro-Hungarian arsenal that became one of the world’s most successful arms manufacturers between the two World Wars. Involved in the manufacturing of arms under the Brno Arms brand. Today Zbrojovka Brno s.r.o, the successor of the former arms producer, is a subsidiary of CZ. Following his book “Zetor Tractors” Arthur Nutbey decided to write a new book on the history and the diversified production of Zbrojovka Brno from the early 1900 to 2003, when the company was forced into bankruptcy. Although a history of diversification, a great part of Arthur Nutbey’s book is dedicated to the company small arms production. For more information visit www.arthurnutbey.com.