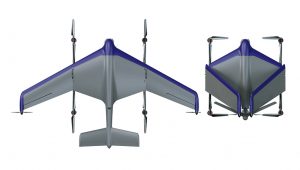

Seafuture 2025 – Pathfinder + Starling Hub, a fixed wing UAS in the box proposed in Europe by Starling and Cyberdife

Rotary wing UAVs “in a box” are becoming quite common, although only a few can operate on the move. Helicopter-like drones have some good and some bad points, speed being one of the latter. With its Pathfinder UAV and its Starling Hub landing and take-off platform, Starling proposes a solution to European customers, through its representative on the Old Continent, Italy-based Cyberdife

Installing a “UAS airport” on a vehicle or at a base, which allows the airframe to land, reload and take-off, thus ensuring a nearly continuous presence of your eyes-in-the-sky, is something that reduces the logistic footprint as well as operational cost, compared to multi-airframes solutions.

Landing pads allowing this type of operation are already available for rotary wing UAS. Starling, a US company based in San Diego, California, developed a similar system, the main difference being that its Starling Hub operates a fixed wing UAS, or to be more precise a hybrid one, as it is capable of vertical take-off and landing (VTOL) operations, although it then flies thanks to wings’ aerodynamic lift.

To maintain the Starling Hub dimensions as compact as possible, a specially designed airframe was needed, which comes in the form of the Pathfinder.

In a way the Pathfinder adopts solutions that we often find on aircraft carrier-based fixed wing aircraft as its wings are hinged at roughly half the span to allow them to fold upwards; the tail boom is also hinged and fold upwards. This allows the Pathfinder size to be reduced from 1.1 x 1.65 x 0.22 metres to 0.705 x 0.705 x 0.50 metres, in order to fit into the Starling Hub, which external size is 0.98 x 0.98 x 0.87 metres. When deployed the landing pad has a 2.1 m2 surface, which means a 1.45 x 1.45 metres.

The airframe features a wing which is a merging between a swept wing and a flying wing, two pods at the wing extremities hosting electric motors activating two-blade pushing propellers which ensure a speed range from 50 to 160 km/h in horizontal flight. At the extremity of the inner semi-wings we find on each side a longitudinal pod carrying rear and forward electric motors activating two-blade propellers, the four of them providing sufficient lift for VTOL operations, the Pathfinder having a take-off mass of 6.0 kg with camera, maximum payload capacity being 1.35 kg. The aircraft body is produced in carbon fibre with Rohacell® [1] core, which offers excellent structural support with minimal mass. In forward flight the aircraft has an over 3 hours endurance, while in hovering this is reduced to 35 minutes; operational endurance depends very much on the flight profile.

Flight range is 155 km. The Pathfinder is fitted with the Halo communication module by Elsight of Israel; it can host multiple SIM cards, ensuring seamless cellular communication across various networks. Should the Pathfinder operate where cellular networks are unavailable, it can be fitted with SATCOM capability.

The Starling UAS “brain” belongs to the Nvidia Orin NX family of small form factor AI computers, the module measuring 69.6 mm x 45 mm with a mass of only 28 grams. This allows the drone to navigate in complex environments, as it is fitted with vision-based navigation, inertial and terrain mapping navigation systems, allowing advanced autonomous operations, the UAS being capable of autonomous decision making should the operational scenario change during the mission. The on-board computing power also allows advanced video analytics, with lidar and radar systems being possibly added to the standard electro-optic sensor package.

Starling is collaborating with leading companies specialized in precision landing algorithms, and integrated cameras and lidar provide real time data ensuring highly accurate positioning, exploiting QR code signs on the landing platform. Something of key importance when a 1.65 metres wingspan airframe must land in the middle of the 1.45 x 1.45 metres landing platform of the Starling Hub, in order to be able to then fold its wings and be recovered within the “box”. Immediately after landing the Pathfinder starts folding its wings and tail, while the sides of the landing platform also fold upwards; when these have reached the vertical position, the central platform starts descending in the box, and the two half of the box cover fold upwards and continue their movement until the box is closed.

The Starling Hub contains three batteries; one is on the airframe in flight, one is fully loaded, while the third is loading. When the Pathfinder is in the box, the battery is swapped with the one fully loaded, an operation that lasts less than 20 seconds. An optional 6 TB storage centre allows to download all data recorded during the mission. Once those operations are finalised, the Pathfinder is ready for operation. The Starling Hub is fitted with four cameras, multiple temperature and humidity sensors, and an external air conditioning system can be added when operating in hot scenarios. Cellular or SATCOM communication capacity can also be added as option. The overall mass of the “box” is less than 60 kg.

The Starling Hub is already in use in the United States, and is therefore considered at TRL 8. Currently the system operates only static, however EDR On-Line understood that the Starling Hub is being further developed to allow it to launch and recover the Pathfinder also on the move, no timeline for this new capacity being provided.

Cyberdife and Starling showcased the system for the second time in Europe at Seafuture, the first appearance being that at Enforce Tac, the exhibition held last February in Nurnberg, Germany.

Graphics and video courtesy Starling, photos by P. Valpolini

[1] Rohacell is the brand name for a high-performance, rigid, closed-cell foam made from polymethacrylimide developed by Evonik Industrie, which is used as a structural foam core in lightweight sandwich constructions.