Leonardo unveils RH1-155/52 HITFIRE artillery system to be installed on tracked or wheeled armoured vehicles as well as on trucks

The increasing importance of indirect fire highlighted by the Russia-Ukraine war is leading to an increase in artillery systems needs by many armies. The Italian Army is one of them, and currently has a requirement for a wheeled system to be deployed with its two medium brigades. Leonardo is answering this need with a new artillery system based on the fully automated RH1-155/52 HITFIRE turret

EDR On-Line was invited with a limited number of Italian defence journalists to the Nettuno experimental firing range, a defence facility that ensures testing and qualification for several types of weapon systems, mostly for land vehicles needing a firing range but not only, Leonardo presenting there its new RH1-155/52 HITFIRE.

“What we would like to show today is the state of development of a new 155mm artillery system, more specifically the loading system for both ammunition and modular charges, the innovative part we developed in the last 18 months,” Luca Perazzo, Deputy Managing Director Defence Systems at Leonardo told the audience. “It is an extremely modern system, capable of growing and evolving over time, and it boasts undeniable characteristics of reduced mass, reduced complexity, and high reliability.”

The full system will be available in mid-2026, Leonardo being working hand in hand with the recently acquired IDV, to produce an artillery system based on an 8×8 armoured wheeled vehicle, and at Nettuno we could observe the first development step, a technology demonstrator that put to test the new automatic loading system, which is the core of the new RH1-155/52 HITFIRE.

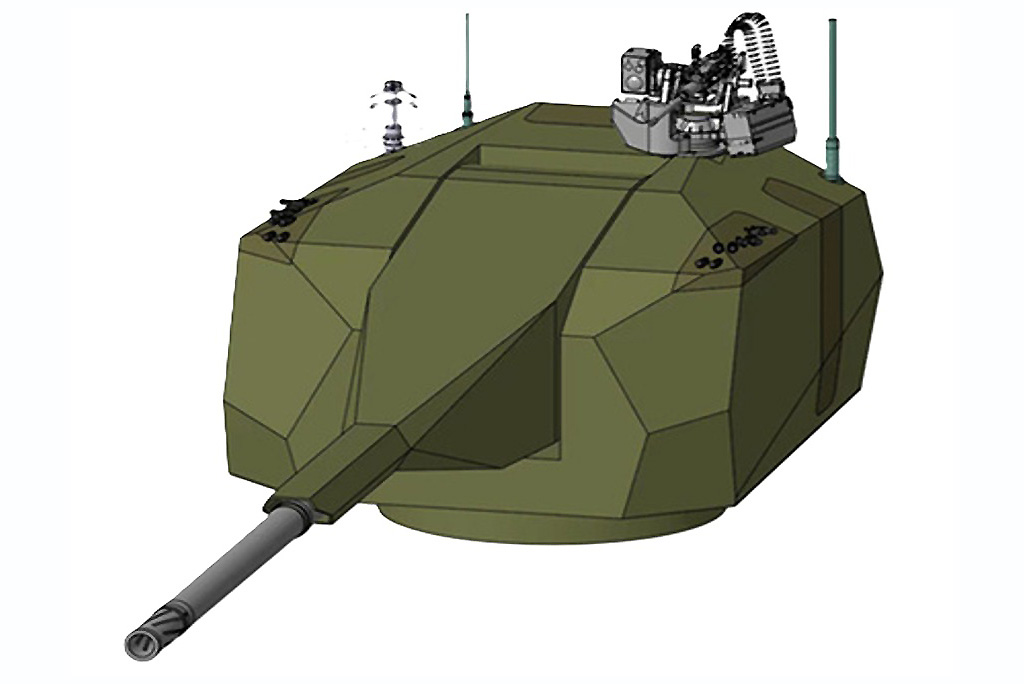

Mass was an issue, and according to information provided the new turret in combat order will be under 13 tonnes. This with the full load of 30 ammunition and 180 modular charges, which allow to fire all rounds in zone 6. It is to note that supercharges and other non-standard charges can also be used.

The 155/52 mm gun is a derivative of that developed by Leonardo in the last few years for two up-gunning programmes that never materialised, one aimed at transforming the M019L from a 39 calibre to a 52 calibre system, this howitzer being in service with several countries, the second to bring the Palmaria 155/41 SP howitzer in the 52 calibre systems family, Argentina, Libya and Nigeria being the three countries that acquired the Palmaria in the past and still maintain some of them in service. The gun features a 23 litres chrome-lined chamber and is JBMOU compliant, the barrel having 48 grooves right-hand rifling with a 20-calibre constant twist rate. The two recoil brakes and the pepperbox muzzle brake allow reducing recoil under 55 tonnes with a limited recoil travel, under 900 mm. The turret was designed to keep the gun trunnions axle as low as possible, which together with the short travel allows keeping the turret shape low, while ensuring a -2.5°/+70° elevation arc.

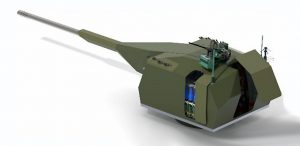

The key element of the new system is however the loading mechanism, which allows loading rounds and charges at any elevation angle. Leonardo engineers aimed at keeping it simple, using the least number of electric motors, mechanics being considered more reliable and easier to maintain. Right and left of the gun we find the two magazines, on the left side the one hosting ammunition, while on the right the one hosting modular charges. Both are of the carousel type and each of them is moved by an electric motor visible on top. The greatest technological challenge was to accommodate in such a small space a quantity of ammunition and grenades sufficient to cover the longest possible mission, according to the design team. The ammunition magazine is compatible not only with standard artillery ammo, but also with the Vulcano rounds, which have two integral charges and are therefore longer. The carousel rotates to bring the type of round required by the command-and-control system in the right position; the round is hold in position by clamps, which open when the robotic arm seized the round, so that the ammunition is always held by a mechanical system, which allows firing on the move, another characteristic of the new turret. Once the ammunition has been seized, the arm brings it to the programming station where the fuse or the Vulcano receives the required data by contact; the arm rotates and loads the ammunition, aligning it with the chamber independently from the elevation. On the right a similar arm deals with modular charges; six charges are held in each column of the magazine, the C2 system requiring the right number of charges which are freed from their clamps, they are then compacted, and when ready a robotic arm, similar to that used for ammunition with the exception of the grabber, which is different to cope with charges, takes them and loads them. A chain-driven rigid chain rammer loads the ammo and charges in the chamber, the primer is inserted in the last charge while the breach is closed, and the gun is ready to fire. The very first time the breach is opened via an electric command, then the recoil energy is exploited to repeat the cycle.

EDR On-Line could witness some firings at the Nettuno range. The system seen is a technology demonstrator, therefore it was fitted with smaller magazines, respectively 10 rounds and 60 modular charges, and the dimensions were not the final one, some more space being kept allowing easier operations. Also, the firing cycle was slower than the final one; this allowed engineers to single out the various movements, the aim at this point being to validate the loading mechanism and not to test the rate of fire. EDR On-Line understood that at the Leonardo La Spezia plant work is already underway on the prototype which should be ready in around seven months. This will be narrower, will feature the actual magazines, and the loading cycle will be optimised, for example compacting charges while the ammunition is being loaded, to allow obtaining the target rate of fire of 10 rounds per minute. Maximum range will be 42 km with base-bleed ammunition and up to 70 km with Vulcano rounds. According to Leonardo the new howitzer will be capable to fire five-six rounds in the MRSI (Multi Rounds Simultaneous Impact) mode.

As anticipated, the loading mechanism is mostly mechanic, as it is fitted with only seven electric motors, two for the magazines, two for the arms, one for the rammer, and two smaller ones in the charge magazine.

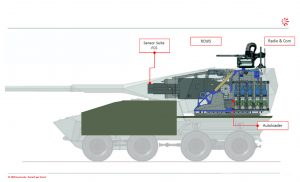

The turret will have a full NVGA (NATO Generic Vehicle Architecture) vetronic architecture and will be fitted with a sensor suite and a C5I (Command, Control, Computers, Communications, Cyber-defence, Intelligence) derived from those already in use in the Italian Army, and its vetronic architecture maintaining high commonality with that of the A2CS (Army Armoured Combat System) currently in development. The RH1-155/52 HITFIRE can be integrated with the JDIFSS (Joint Digital Indirect Fire Support System).

The turret shield will ensure a certain ballistic protection, which level remains classified. A self-propelled howitzer is not a front-line effector, however it is definitely a target of choice therefore a number of self-protection systems will be installed. Firstly, the ballistic protection level can be increased according to customer’s requirements, as the basic structure is capable to accept add-on armour; EDR On-Line understood that the basic shield might be made of composite materiel, Leonardo being currently working on a series of innovative protection solutions. The turret will be fitted with a laser warning receiver, allowing to detect incoming laser beams generated by rangefinders or designators, smoke grenade launchers providing multispectral screening. However, the main defence against drones will be the HITROLE remotely controlled weapon station (RCWS) installed on the roof. Leonardo considers the RCWS currently under development armed with the Blaze30 30×113 mm gun cannon which is also in the final development stage, and which will be capable to use an airburst round which is being developed by KNDS Ammo Italy. A lighter HITROLE RCWS armed with a 12.7 mm machine gun can also be fitted.

Developed on company funds, and without any commitment from the Italian Army, Leonardo nonetheless is considering an in-house solution not only aiming at the national requirement but also looking at the export market. The choice fell on the VBM Plus 8×8 platform, which is being modified to better fit the artillery system needs; the VBM Plus is currently in production, a contract to produce 76 such vehicles having been signed on December 30th, 2024. EDR On-Line understood that the distance between the second and third axles is being widened by around 450 mm, which will allow a better distribution of the turret mass on the two rear axles. This will take the place of the rear troop compartment, the rear floor height being reduced compared to that of other competitors, according to Leonardo. This, together with the already mentioned reduced recoil, will allow the SP howitzer to shoot on all 360° not only in indirect fire, but also in direct fire, should this need arise, and at 3- and 9 o’ clock from a negative slope. Leonardo engineers made it clear that the new artillery system will be capable to shoot on the move, which is one of the key requirements of the Italian Army.

The howitzer will have a crew of two, driver and commander; these will be seated in a tandem configuration on the front left side of the vehicle, and both will be able to carry out some duties, for example EDR On-Line understood that both will be able to control the RCWS. The overall combat mass of the system will be under 35 tonnes, the engine being boosted to 720 hp to ensure an over 20 hp/t power-to-mass ratio. The overall length with the gun at 12 o’clock will be 11 metres, width being less than 3 metres while height will be less than 3.6 metres without the HITROLE RCWS.

Of course, the new 155/52 mm turret can be installed on other armoured wheeled vehicles, as well as on tracked platforms, and even on trucks.

The reduced crew led the Leonardo design team to consider an automated solution for reloading the howitzer, which needed soldiers to expose themselves to possible threats for the least possible time. Two apertures will be available at the outer rear of both magazines, while a reloading module is being designed that will be installed on a platform. This will flank the howitzer and a robotic arm, quite probably a derivative of those used in the autoloader, will ensure reloading with the crew remaining in the protected cabin. The only manual reloading will be needed for primers, but considering their dimensions and the limited number this should be a quick operation.

Leonardo aims completing industrial qualification probably late 2026, early 2027.

All graphics courtesy Leonardo