Seafuture 2025 – Intermarine unveils first details of Italian Navy New Generation Minehunters

On 25 September, Intermarine shipbuilder (IMMSI industrial group) started the hull lamination of the first Cacciamine di Nuova Generazione Costiero (CNG-C) New Generation Minehunter Coastal (NGM-C) commissioned by the Italian Navy. The NGM fleet programme consists of two batches, the first of eight Coastal platforms while the second one should consist of four NGM in larger size for expeditionary operations. The NGM is the newest member of the family of dedicated platforms which Intermarine presented officially for the first time during the Seafuture 2025 exhibition

Current conflicts and crisis confirm the strategic relevance of mine warfare and show how naval mines remain a strategic asset, as well as a sophisticated and insidious offensive weapon with an impressive psychological and deterrent power. As the recent operations in the Black Sea showed, even today, enemy minelaying operations could be sufficient to cause an immediate disruption of maritime traffics, with consequent economic damages worldwide, highlighted the Intermarine representative. The Italian Navy current mine countermeasures force consists of 10 Gaeta-class/Lerici-class units, the most modern being nearly 30 years old; with the acquisition of the NGMs the service intends to renew it within the 2030s.

The two NGM versions, 63 meters length for the Coastal version and 81 meters for the expeditionary version, both in composite materials, are designed to maintain the traditional minehunter’s specific characteristics of low magnetic signature and high shock factor, provided by the technology developed by Intermarine, which allowed international success worldwide, with 44 minehunters sold (plus eight under construction) in different configurations to answer different Navies’ operational requirements.

Although other naval forces are experimenting new methodologies to conduct mine countermeasures (MCM) operations exclusively with uncrewed systems, the operational philosophy adopted by the Italian Navy focuses on using dedicated platforms built with composite material to prevent mines activation. The limitations still presented by unmanned vehicles technology, the fast evolution of sea mines, the impossibility of defining the boundaries of a mine threat area and the necessity of operating and keeping the crew safe in the vicinity of mine threats, have clearly demonstrated the importance to maintain dedicated MCM vessels (MCMVs), characterized by the capability to operate safely inside the minefield, thanks to high resistance to underwater explosions and low magnetic and acoustic signatures.

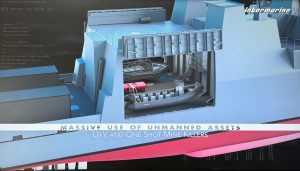

Combining these traditional MCMV characteristics with advanced technologies and the extensive use of autonomous vehicles to operate across the whole underwater spectrum provide the NGM designed by Intermarine, the modularity, interoperability and multi-mission capabilities requested by the Italian Navy. Other operators have expressed interest in the same philosophy, starting from NATO countries.

With a risk reduction/definition phase contract, awarded by Italian MoD’s Naval Armaments Directorate to Intermarine in 2021, the programme for the development, design, construction outfitting, delivery and in-service support of a family of two NGM platforms for the Italian Navy, respectively of 63 and 81 metres length, and 1,300 and 2,100 tonnes displacement was launched, culminating in a contract awarded, so far, for the Coastal Version – NGM-C – and its integrated logistics support to Intermarine and Leonardo in a temporary grouping of companies in July 2024. The € 1.6 billion deal includes the delivery of five vessels and the addition of approximately € 1 billion options for the completion of the programme with other three units in order to achieve a total of eight NGM-C. While the shipbuilder is leading the programme and is the ship design authority providing the platform systems, Leonardo is the design authority and supplier of the combat system. To cope with the new platforms construction and other contracts, including new patrol vessels for the Italian Coast Guard, Intermarine has built a new production hall 100 metres long, 65 wide and 27 high for shipbuilding activities with new adjacent buildings and other improvements while a new dock 89 metres long, 20 metres wide and 10 metres deep with lift equipment is planned for the shipbuilding site at Sarzana, near La Spezia, the company workforce being also expected to grow in the coming years.

With a requirement for a critical mass of at least 12 MCMVs, the Italian Navy has launched the acquisition programme of the first batch while the requirement for the bigger 81 metres expeditionary platform, also made in composite materials, which feasibility activities were part of the already mentioned risk reduction/definition phase, is still pending.

In addition to mine warfare operations, the current operational requirements dictate the need to conduct operations for the surveillance and protection of critical underwater infrastructures as well as exploitation of seabed resources, preservation of cultural heritage, safeguarding of the maritime environment, and hydrographic mapping of sea bottom. To conduct these missions, Intermarine has developed a platform with a modular area for mission tools capable to accommodate containerized payloads ranging from remotely operated vehicles (ROVs) to autonomous underwater vehicles (UAVs), from one shot mine killers (OSMKs) to influence sweeping modules, from hyperbaric chamber for divers to working class ROVs and logistic equipment. Moreover, the ship can accommodate Unmanned Aerial Vehicles (UAVs) with a flying spot, on top of the mission bay. The ship conduction is based on a “naval cockpit” while the combat system is centred on a command “multi domain” management system and a sensors suite that includes a variable depth sonar (VDS) for MCM operations, as required by the Italian Navy.

With the risk reduction/definition phase contract, Intermarine has further evolved and demonstrated the application to larger platforms of its unique and patented construction technique called “Monocoque single-skin without reinforcement” in composite materiel, the bigger units produced until now with that technique being the modernised 52.5 meters Italian Navy Gaeta-class and Finnish Navy Katanpaa-class MCMVs. The technique developed by the Sarzana-based shipyard consists in designing and building the hull without any longitudinal nor transversal structures, increased shell thickness providing the hull with the required structural strength. This allowed to exploit at utmost the elasticity and flexibility of GRP, and therefore to build vessels capable to withstand the shock caused by underwater explosions of mines by “absorbing” the enormous energy released by the explosion. The engines and main machineries are installed with specific and unique solutions allowing not only the proper functioning of the propulsion system under shock load but also providing additional benefits in terms of silent navigation and therefore higher safety for the vessel and the crew when navigating in proximity of a mine threat. The platform has reduced magnetic and acoustic signature in order not to activate the logics of modern mines.

The Italian Navy and Intermarine conducted an “impressive phase of feasibility and de-risking studies”, aimed to define the optimal design for the new mine warfare platforms, propulsion and mission systems, alongside a live explosion test campaign on a ship section equipped with monitoring equipment in the Gulf of La Spezia. The resulting analysis conducted for the NGM showed that the structural solutions adopted by the shipyard guarantee the best dynamic response to underwater explosions, despite the enlarged dimensions and displacement of the new platforms compared to those currently in service. These were subjected to nearby live underwater explosion testing respectively in 1995 by the US Navy (Osprey-class) with personnel on-board and in 2013 by the Finnish Navy (Katanpaa-class).

During the live explosion campaign conducted by the Italian Navy’s Support and Experimental Centre (CSSN, Centro Supporto e Sperimentazione Navale), a representative stern mission bay and propulsion section of the new smaller platform equipped with monitored mannequins and test equipment was used. Based on qualitative evidence, an underwater explosion created by a modern sea-mine placed at less than 50 meters is expected to provide minimum or insignificant damage to the composite material-made MCMV while the damage created to the steel hull platform would cause a significand damage or sink. At the same time, the magnetic signature is significantly higher for the steel hull platform, resulting above the activation level of the sea mine threshold during the simulation with a magnetic sensor placed at 25 metres depth.

The new generation 63 metres MCMV

With a full load displacement of 1,300 tonnes, a length and beam of respectively 63.08 and 12.50 metres, the coastal MCM is equipped with a propulsion and dynamic positioning system based on two electric cycloidal propellers and two bow thrusters used for operational transits as well as for MCM operations inside the minefields. The platform can reach a maximum speed of 14 knots and has a range of 1,500 nm at economical speed. Intermarine hasn’t provided details on the propulsion system configuration, but EDR On-Line understood it is full electric with three diesel generators of unspecified power connected to the two electric cycloidal propellers, each equipped with an integrated electric motor. No information was released about the electric cycloidal propellers provider – a couple were considered – and the ship diesel generators, but according to newspaper sources, MTU supplies the latter which also provide electrical power to the platform and combat systems.

Based on the design seen, the 63 metres platform features single-block full width superstructures which forward section includes the main bridge with the naval cockpit providing a full 360 degrees visibility, the combat operation centre and accommodations and living for the crew of 40 plus 10 additional. The ship design enhances personnel safety as all crew accommodations are positioned above the waterline. The rear section accommodates the mission payload bay while the ship stern main deck area can accept up to two 20’’ standard containers that can deploy different mission tools as vehicles and systems.

The mission bay features two large rear-positioned lateral up-opening doors for the launch and recovery of vehicles and systems through a traversal overhead crane system. According to the company’s video images, a storage for the countercharges and other equipment is positioned underneath the mission bay. Although no information was released by Intermarine about the MCM suite which can be accommodated in the mission bay and ship stern area including the one selected by the Italian Navy, the baseline one can include ROVs, AUVs, and one OSMK, influence sweeping, diving and defensive mine laying equipment, unmanned surface vehicles (USV) and RHIBs for different missions. The two lateral doors dimensions allow for 6-8 metres long manned or unmanned platforms. On top of the rear section superstructures a vertical operating area (VOA) is available for UAV operations.

Similar in concept to the Multi-Purpose Combat Ship/Pattugliatore Polivalente d’Altura (MPCS/PPA) innovative bridge configuration, the Intermarine-designed bridge accommodates a naval cockpit developed by the same shipbuilder, an undisclosed number of operator consoles and the commander station. The combat operation centre is positioned behind the main bridge.

Leonardo, as anticipated, is the design authority and supplier of the combat system, which is based on the cyber-resilient SADOC 4 command and control system already installed on the newest Italian Navy frontline platforms. The embarked SADOC 4 version, EDR On-Line understood, includes a software package specifically developed for the MCM missions based on the developments and lessons learned with the previous generations of mission-oriented CMS provided by Leonardo and its previous historical brands Datamat and Selex. Although no official information was released, EDR On-Line understood an autonomous vehicles managing system called SIGEVA (Sistema Gestione Veicoli Autonomi) and developed by Leonardo will be part of the MCM controlling suite. The Leonardo CMS manages the ship communications, sensors, weapons and MCM suite including the new hull-mounted VDS, manned and unmanned vehicles. The new NGMs for the Italian Navy are equipped with an integrated multi-communications bandwidth and data link suite to ensure the highest and most effective level of interoperability provided by Leonardo and including software-defined radios in different bands, the Multi-Data Link Processor (MDLP) with Data Link 22 and 16 capabilities, civil and military SATCOMs.

The sensor suite includes a Columbus 3D radar which provides air and surface surveillance at significant distances, a dual-band navigation radar from GEM Elettronica, and a day/night surveillance system with two Janus electro-optical turrets from Leonardo. The same company also provides the two Lionfish 12.7 mm Remotely-operated Weapon Systems (RWS) positioned in front of the main bridge, space and accommodations being available for two additional systems at amidships lateral stations. The self-protection suite includes the Sitep Italia MASS system featuring two turrets with surveillance sensors and non-lethal effectors, an ESM suite and decoy launchers as an option.

The MCM sensors and vehicles suite is centred on the new VDS being developed by Fincantieri WASS. The new sensor represents a significant and first development for national industry in the specific mine warfare field, using latest generation technologies and enhanced human-machine interface (HMI) capabilities. The sonar features a new electronic steering transducer array without moving parts, which increases reliability and improved HMI, being developed with the support of national customer’s crew to implement solutions that can enhance operational effectiveness. The deployment and recovery system are designed and produced by Fincantieri’s company Remazel.

Intermarine hasn’t released further information on the MCM suite to be installed on NGM-C platforms, but a baseline equipment will be the Hydrone-D MCM hybrid ROV/AUV system by Saipem (two systems for each ship). The new platforms allow the embarkation of a comprehensive suite of containerized mission payloads including ROV, medium-large AUV, decompression chamber, OSMK, logistic, as well as command and control equipment, in addition to unmanned surface vehicles as well as RIHBs.

The new generation 81 metres MCMV

The larger platform project presented by Intermarine represents a unique and most innovative design for a MCMV in composite materials of these dimensions, displacement and capabilities at worldwide level. It seems to be a game charger, which has attracted interest from worldwide Naval Forces. EDR On-Line understood many Navies have shown interest in the new design.

With a 2,100 tonnes displacement at full load, a length and beam of respectively 80.95 and 14.50 metres and a propulsion system capable to reach 18 knots and an endurance of 3,000 nm at 14 knots, the new platform has been conceived as an ocean-going platform with expeditionary capabilities, as it will operate in far aways areas of operations, integrated into joint task forces and for extended periods of time.

The new MCMV has a longer and large hull fitted with extended superstructures with a longer and wider mission bay and accommodation for a 50-man crew and 10 additional personnel, in addition to larger food and fuel reserve to extend the operational endurance. The propulsion system is based on the same configuration of the smaller platform but is based on four diesel generators and possibly more powerful electric cycloidal engines. Armed with four 12.7 mm RWS, its combat system could include an electronic warfare suite, which is considered an option on the smaller platform, together with decoy launchers for protection against missiles and asymmetric threats. The 81 metres MCMV combat system maintains the same but enlarged CMS as well as sensors, including the VDS.

The longer and wider mission bay has two up-opening doors of two different sizes on each side: the forward area accommodates the larger doors capable to operate USVs while the rear mission bay area presents the smaller ones for RHIB-size vehicles. Moreover, the stern ship area can accommodate three instead of two containers, significantly increasing the MCM and other mission tools to extend the ship operational capabilities.

Graphics courtesy Intermarine, photos by L. Peruzzi