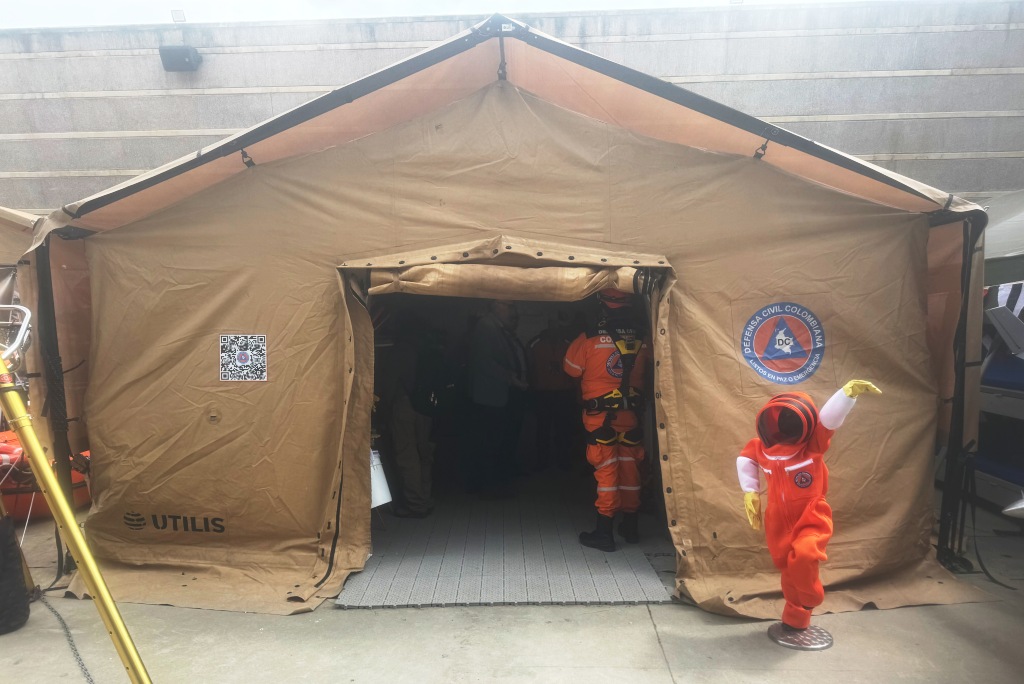

Expodefensa 2025 – Utilis showcased its modular deployable tents system

Utilis of France has developed a comprehensive family of modular field tents designed for armed forces that need to project command, medical support, accommodation, and storage capabilities as close as possible to the front line. These shelters, showcased at ExpoDefensa in Bogotá, have become a key element of theatre logistics: without them, it is impossible to sustain a combined-arms task force overtime on a highly mobile battlefield exposed to severe climatic and ballistic constraints

On today’s theatres of operations, Utilis tents fulfil several critical roles: rapidly deployable command posts, triage and treatment facilities, protected rest areas for rotating units, light technical workshops and controlled storage spaces. Their modular architecture allows a camp to be quickly reconfigured to follow the manoeuvre, for example by converting an accommodation structure into a forward medical post or a tactical command post depending on how the mission evolves.

These tents also meet the growing requirement for “low‑signature camps”: reduced thermal footprint through insulating liners, fabric colours and treatments adapted to desert, woodland or snow-covered environments, and compatibility with new-generation camouflage nets. Coupled with generators and C4ISR systems, they become genuine functional “bubbles” capable of projecting a Role 1/2 field hospital, a battalion CP or a forward operating base in just a few hours.

Utilis field tents are generally built around frames made of light alloys (high-strength aluminium) or composite materials to combine rigidity, low weight, and rapid assembly. The arches are segmented and articulated, enabling deployment by two or three operators without heavy tools and compact stowage for air transport (C-130, A400M, heavy helicopters) or road convoy.

Each module is designed to operate either independently or interconnected with others: link-up via sealed vestibules, pre-equipped entrance porches, adjustable feet to compensate for uneven ground and anchoring systems optimised for both soft and rocky soils. This modular architecture makes it possible to build complex configurations – field hospitals, multi-room command centres, disengagement zones – while keeping the logistics chain simple.

The outer skins are typically made from multi-layer technical textiles, often based on high-tenacity polyester or polyamide, coated with PVC, PU, or other flame-retardant finishes compliant with NATO fire safety standards. These materials are dimensioned to withstand strong winds, intense UV radiation, heavy rain, dust and sand, with mechanical resistance margins sufficient to bear snow loads and storm gusts.

Certain configurations are available with reinforced walls, light ballistic liners or inner liners providing advanced thermal insulation, which helps maintain acceptable working conditions in extreme climates (arctic or desert zones) while reducing the energy consumption of heating and air-conditioning systems. Anti-fungal and anti-mould treatments extend the service life of the fabrics in humid or tropical environments, which is a decisive factor for long-duration deployments.

In terms of dimensions, Utilis field tents are generally proposed as standard-width modules (for example 4 to 6 metres) with length extended by bays, allowing the usable floor area to be tailored to operational needs – from a small primary care tent to a full hospital ward or a brigade CP. The ridge height is designed to allow personnel to move around upright and to accommodate racks, servers, partition walls and overhead cable runs without impeding movement.

Interior ergonomics integrate dedicated attachment points for lighting, air-conditioning and ventilation ducts, as well as electrical and IT networks, so that heaters, air conditioners, CBRN filtration systems or technical shelters can be connected quickly. Several solutions include integrated or raised flooring, ensuring a level surface, keeping personnel clear of ground moisture and allowing cable routing under the floor to secure circulation routes and reduce the risk of trips and falls.

One of the main strengths of Utilis tents lies in the reduction of assembly and dismantling times, often down to a matter of minutes for a trained team, which is crucial for expeditionary forces and rapid-reaction units. Packaging in standardised containers and pallets simplifies loading onto air, sea or land assets and streamlines multinational support chains.

Finally, the support philosophy focuses on first-line maintenance by the user units: easily replaceable wear parts (fabrics, guy lines, pegs, connectors), clear documentation and maximum compatibility between the various tent families and associated kits (heating, air-conditioning, CBRN, lighting). On the battlefield, this approach reduces downtime and ensures that protection, command, and life-support capabilities remain continuously available despite wear and frequent relocation.

Photos by J. Roukoz