Expodefensa 2025 – Colombian Navy, the Strategic Surface Platform (PES) Report 2025

The Strategic Surface Platform (PES) programme is the most ambitious naval project in Colombia’s modern history. At Expodefensa new detailed information on the programme were made available

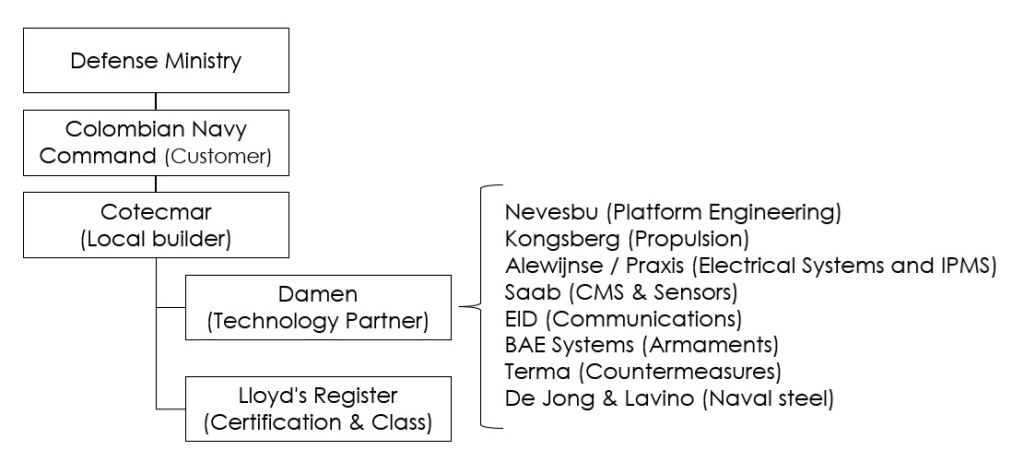

Led by the Colombian Navy and executed by the Colombian shipyard COTECMAR in cooperation with Damen Naval (Netherlands), the PES seeks to design and build a new class of high-capacity frigates tailored to the country’s maritime defence needs.

The project not only renews the surface fleet but also strengthens the industrial and technological autonomy of the national defence sector, consolidating Colombia as a regional leader in military shipbuilding.

Strategic level: Government and general management

| Actor | Role / Responsibility | Observations |

| Ministry of National Defense | Policy formulation and monitoring of the PES program. | Defines guidelines, budget and political-strategic control. |

| Colombian Navy Command | Institutional client and end user. | Responsible for operational requirements, tactical specifications and design validation. |

| COTECMAR | National main contractor and local builder. | Leads project execution, manufacturing, local integration, and receipt of technology transfer. |

| Damen Naval | Technology partner and principal engineer. | Provides engineering, technical assistance, logistical support, technology transfer and equipment packages. |

Industrial and technical level (alliances and suppliers)

🔹 Design, engineering, and certification

| Company | Country | Role |

| Damen Naval | Netherlands | Basic design (SIGMA 10514), detailed engineering, documentation provision and technical support. |

| COTECMAR – Naval Engineering Directorate | Colombia | Local adaptation of the design, integration with shipyard infrastructure, construction planning. |

| Nevesbu | Netherlands | Platform engineering (structure, compartmentalization, naval architecture). |

| Lloyd’s Register | United Kingdom | Design classification and plan approval, ensuring compliance with international standards. |

🔹 Propulsion, power, and platform control

| Company | Country | Role |

| Kongsberg Maritime | Norway | Supply of propellants (CPP propellers, shafts, control mechanisms). |

| Praxis Automation Technology | Netherlands | Supply of the IPMS (Integrated Platform Management System). |

| Alewijnse Marine Systems | Netherlands | General electrical integration, wiring and control systems. |

| Van Meer | Netherlands | Electrical subcontractor (motors, panels). |

🔹 Combat system and sensors

| Company | Country | Role |

| Saab AB | Sweden | Supply of the Combat Management System (CMS 9LV), Sea Giraffe 4A radar , Ceros 200 fire directors and EOS 500 optronic sensors. |

| EID SA | Portugal | Supply of the ICCS integrated communications system. |

| Terma A/S | Denmark | Guard countermeasure system (decoy launcher). |

| BAE Systems Bofors | United Kingdom | Main armament: Bofors 40 Mk4 naval gun. |

🔹 Materials and structure

| Company | Country | Role |

| De Jong & Lavino (DJL) | Netherlands/Belgium | Supply of certified naval steel. |

| COTECMAR / national suppliers | Colombia | Hull cutting, assembly, and welding; integration of local components where possible. |

🔹 Supervision, quality control and technology transfer

| Company / Entity | Function |

| Damen Naval | Provides resident engineers and technology transfer manuals. |

| COTECMAR | It implements technical training in shipyards, training Colombian welders, electricians, and naval engineers. |

| Lloyd’s Register | Monitors compliance with class standards during construction. |

General operational schedule (according to public information 2024–2030)

| Phase | Period | Description |

| 1. Engineering and detailed design | 2024-2025 | Validation of the adapted SIGMA 10514 design, approval of plans and contracts with key suppliers. |

| 2. Industrial preparation and steel cutting | 2025-2026 | Shipyard adaptation, reception of materials and technical training. |

| 3. Modular construction and assembly | 2026-2028 | Manufacturing of sections at COTECMAR, installation of main systems. |

| 4. Integration of combat systems | 2028-2029 | Installation of the Saab CMS, radar, propulsion and electrical systems. |

| 5. Testing and operational readiness | 2029-2030 | Dock and sea trials; official delivery to the Colombian Navy. |

Contractual flow and functional hierarchy

General operational schedule

| Phase | Period | Description |

| Engineering and design | 2024-2025 | Validation of the adapted SIGMA 10514 design, approval of plans and contracts with key suppliers. |

| Industrial preparation | 2025-2026 | Shipyard adaptation, reception of materials and technical training. |

| Modular construction | 2026-2028 | Manufacturing and assembly of structural blocks and sections at COTECMAR, installation of main systems. |

| Systems integration | 2028-2029 | Installation of the Saab CMS, radar, propulsion and electrical systems. |

| Testing and delivery | 2029-2030 | Dock and sea trials; official delivery to the Colombian Navy. |

The PES programme is a milestone in international cooperation and industrial innovation for Colombia. It integrates industrial cooperation, technology transfer, and local capacity building.

The project is part of the Defence Sector’s Technological Sovereignty Policy and the National Navy’s “Vision 2042” plan.

The PES will be the largest vessel built in Colombia and a benchmark for international industrial cooperation. The program’s success will strengthen the country’s technological sovereignty and maritime projection.

Working with Damen Naval, Saab, Kongsberg, BAE Systems and other European firms ensures quality standards comparable with the world’s leading navies, while driving the development of sustainable, autonomous local capabilities.

The contractual model is based on a comprehensive technology transfer scheme, with Damen Naval providing engineering, support, and critical components, while COTECMAR executes local construction. This establishes the country’s capacity to build large warships. In this way, COTECMAR consolidates its position as the most advanced shipyard in Colombia and a regional benchmark.

The resulting vessel will be the most modern frigate in South America, partially built in Colombia. The first unit is expected to be launched by late 2029 or 2030, depending on the pace of systems integration.