Bren-Tronics: further improving battery capacity

Carrying four batteries instead of five in order to have the same endurance for powered systems is among the dreams of all soldiers, the weight of their rucksacks being constantly on the increase. At the heart of the SWAP (Size, Weight And Power) reduction concept we find batteries, and one of the major suppliers of those vital elements, Bren-Tronics, is definitely aiming at increasing by some 20 per cent its Lithium-Ion batteries power density.

Based in the State of New York, this 47 years old company is specialised in energy storage applications, which include rechargeable and non-rechargeable batteries, smart chargers and complete power systems. In Europe the company has two operational units, one in France, Bren-Tronics International Solutions (BIS), which handles international orders and project management with international customers, and one in Turkey, Brensan Energy and Defence, a joint venture with a local company, which mostly acts as a technical office and production facility for limited series.

The last 20 years having been dominated by Lithium-Ion batteries

“In the last decades Bren-Tronics, with the support of the US Department of Defense, has carried out technological innovation in order to provide the military with lighter, more energetic, more resistant and safer batteries, the last 20 years having been dominated by Lithium-Ion batteries, at least for portable systems,” Sylvain Lhuissier, Bren-Tronics VP International and General Manager of BIS tells EDR On-Line. The increasing need of power for man-portable systems, such as sensors, jammers, optronic and robotic systems, led to a surge in Li-Ion battery production for military use and to a continuous search for better performances. Bren-Tronics increased its battery capacity every 2-3 years, and even if scientists see the Li-Ion solution approaching the horizontal asymptote, the company is still working on major improvements.

“Bren-Tronics started a collaboration with California-based American Lithium Energy (ALE), a company funded in 2006 that developed a patented lithium battery safety technology, of which it also acquired part of the shares,” Lhuissier says. While power density remains a key issue for the soldier, another vital parameter is definitely safety, Lithium being 5-6 times more reactive compared to lead in generating flames and gas in case of external aggression. “This can come in three forms, thermal, putting the battery in a fire, electrical, by loading it without respecting safety parameters, and mechanical, which is the most relevant to soldiers as a short circuit can be caused by a bullet striking through the battery,” he explains, adding that the latter case might bring to a thermal runaway that in turn generates a chain reaction with adjacent cells. ALE worked on reducing those effects in two ways. The first one, which is of common knowledge, involves the use of a non-flammable organic electrolyte that delays a possible thermal runaway. The second, which is a proprietary and patented solution, involves the coating of electrodes depositing a thin layer of specific materiel that, in case of short circuit, reacts isolating the area and avoiding the overheating of the damaged cell. This solution has been thoroughly tested on batteries ranging from man-portable ones up to those dedicated to vehicles, and not only at company level but also by independent centres and customers, such as the German Bundeswehr Wehrtechnische Dienststelle 41 based in Trier, and specialised in vehicles testing.

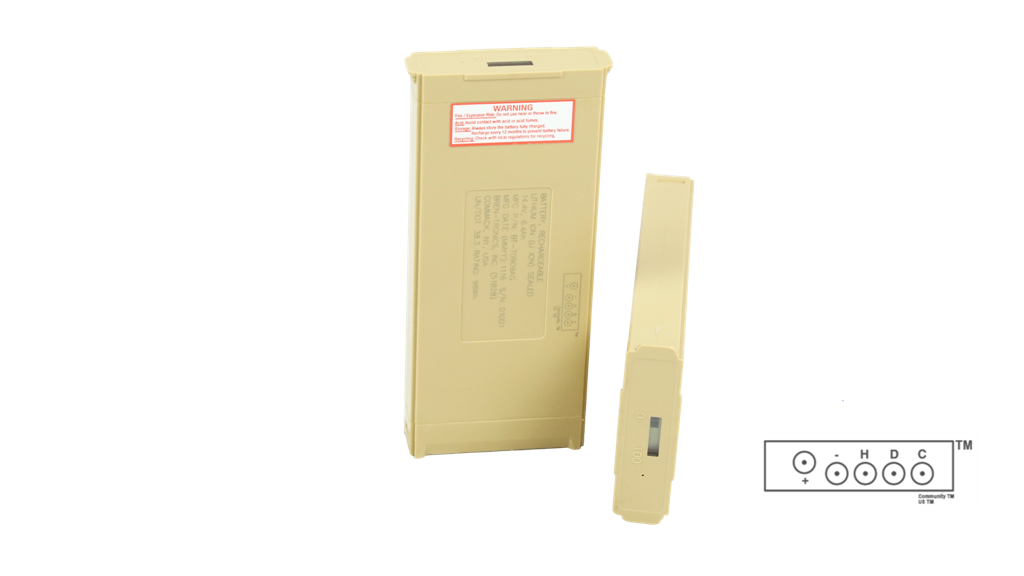

“Once the safety problem solved, the other objective was to increase the single cell capacity. The standard cell size has always been driven by commercial rather than military requirements, and until now the standard one was the 18650 Li-Ion cell [1], which started at 1.5-1.6 Ah in the early 2000 to reach 3.5 Ah in current times, the theoretical limit having been put around 4 Ah,” Lhuissier details. The need for higher power batteries is leading to a major change on the commercial market, mostly driven by the automotive market, the new standard for Li-Ion cells being the 21700, which bigger dimensions allow for more energy and power, current top products reaching 5 Ah. That said, in the military word most battery-powered systems rely on standard batteries, therefore changing the form factor of military batteries becomes nearly impossible, and eventually extremely expensive, in the short-medium term. Hence the need to further improve the capacity of the 18650 cells, which is exactly what Bren-Tronics and ALE are currently doing. “The challenge is to increase the cell capacity by 20-25 per cent,” Sylvain Lhuissier tells us, “therefore some 18 months ago we launched a roadmap that should allow us to further evolve the current cell capacity for the next 15 years,” he adds. The joint effort has already led to an 18650 cell with a 4Ah capacity, which is currently under industrialisation in the United States with a partner company. Bren-Tronics is ready to introduce those cells in other countries, however only in friendly ones such as Europe, Japan and South Korea. Bren-Tronics aims at having its new batteries available in 12-18 months, their power density being increased from the current 210-215 Wh/kg to 265 Wh/kg.

In time the SWAP concept has evolved into the SWAP-C concept, the “C” letter indicating cost. Should the civil market shift entirely on the 21700 standard, the number of 18650 ones produced yearly will dramatically decrease, furthermore the current energy density level for the 18650 cell seems to be sufficient for commercial uses, thus R&D non recurrent costs will have to be spread solely on cells produced for military use, some millions per year compared to the billion cells currently manufactured, which will inevitably bring to higher costs. That said the move towards improved capacity batteries is considered a must by the US DoD, the rest of the western world eventually benefiting for this R&D effort.

From his position as VP International and head of BIS Sylvain Lhuissier is closely monitoring the possible market reaction outside the US: “we still have to convince the OEMs we are working with of the competitiveness of our new technology,” he underlines, although some of them have already shown interest in the new standard. A huge advantage of the battery world is that being a dual-use product it is not linked to the US ITAR [2] procedures and regulations, so the new batteries will be readily available to the international market, the only hurdle to be overcome being economical, seen under a cost-performance perspective. That said, three levels of batteries are currently proposed, Tier 1 high-end product is based on 3.5 Ah cells, Tier 2 on 2.9 Ah cells and Tier 3 on 2.6 Ah cells, a reference cost being 1 for the latter, roughly 1.5 for Tier 2 and 2 for Tier 1. A rough estimate of the latest development, which industrialisation is still ongoing, brings to a possible cost of 4, its advent probably bringing to discontinuing the production of current Tier 3 batteries in order to maintain the three-tiers system.

In the US the Bren-Tronics market is evolving, and from Li-Ion batteries with a few Wh capacity for soldier systems it evolved into batteries with some KWh capacity for bigger systems, such as vehicles, and into packages with some tens of KWh, aimed at energising complete shelterised systems with hybrid power supply.

This translates into new possibilities also on the international market: “we are part of the French GICAT land defence industry working group on power, including hybrid vehicles,” Lhuissier says, “and we are proposing batteries with better safety and performances to the team, which is led by Arquus [3].” This might not be the only target for the international arm of Bren-Tronics, as i.e. Otokar of Turkey also has an all-electric/hybrid vehicle underway, while the interest for Li-Ion solutions for vehicles is definitely increasing.

“In the last eight years Bren-Tronics invested roughly 2 million US$ per year in France for its international businesses. The current assets allow us to have a good flexibility, the Paris company dealing with the export market while the Ankara-based company is a key element for our penetration in Turkey, providing high local content, and in providing us flexibility when we must answer specific customers requests on small series contracts,” Bren-Tronics VP International and BIS General Manager states.

However Li-Ion improvements at Bren-Tronics and ALE have not yet reached an end: “we continue working, and we aim at bringing the 18650 cell to 4.5+ Ah in the next 10 years,” Sylvain Lhuissier concludes. Then, quite probably, a new technology will have to be adopted to further increase specific energy and power density such as solid state; another path being investigated by Bren-Tronics

Photos courtesy Bren-Tronics

[1] The number shows the cell dimension, in this case 18 mm x 65 mm, respectively the diameter and the height.

[2] International Traffic in Arms Regulations.

[3] Arquus, formerly Renault Trucks Defence, developed a hybrid VAB and is currently testing its Scarabée, an innovative hybrid 4×4 scout vehicle unveiled at Eurosatory 2018 and that should have been one of the company stand stars at the 2020 edition.