BAE Systems Hägglunds and Saab: Additive Manufacturing, the future of spare parts

6 November 2024 – BAE Systems Hägglunds is ready to take a revolutionary next step in Additive Manufacturing (AM) together with partner SAAB. A generic AM capability will greatly benefit their customers with this new capability to manufacture parts and shorten lead time from approximately 30 weeks to four weeks.

Additive manufacturing (AM), also known as 3D printing, is having a profound effect on industrial manufacturing processes. AM can translate the most complex computer aided designs and offer precision, repeatability and material range that traditional methods cannot replicate.

The aim of the collaboration between BAE Systems Hägglunds and Saab is to create generic AM capability that will benefit the customer and secure their supply of spare parts. First up is finding the generic work methods and processes required for 3D printing.

“BAE Systems Hägglunds and Saab will explore a new area and share experiences within the field of new manufacturing which can influence the future logistics in both defence and non-military industries. We will do this in close collaboration with our customer to ensure that this benefits them and their security of supply,” said Lars Pettersson, Director of Engineering at BAE Systems Hägglunds.

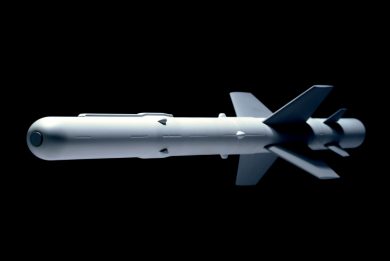

“Additive Manufacturing is at a stage where it can be really useful for defence applications, so now is the perfect time to involve the customers to make sure that they can guarantee the security of supply in times of crisis and war,” said Petter Bedoire, Chief Technology Officer at Saab.

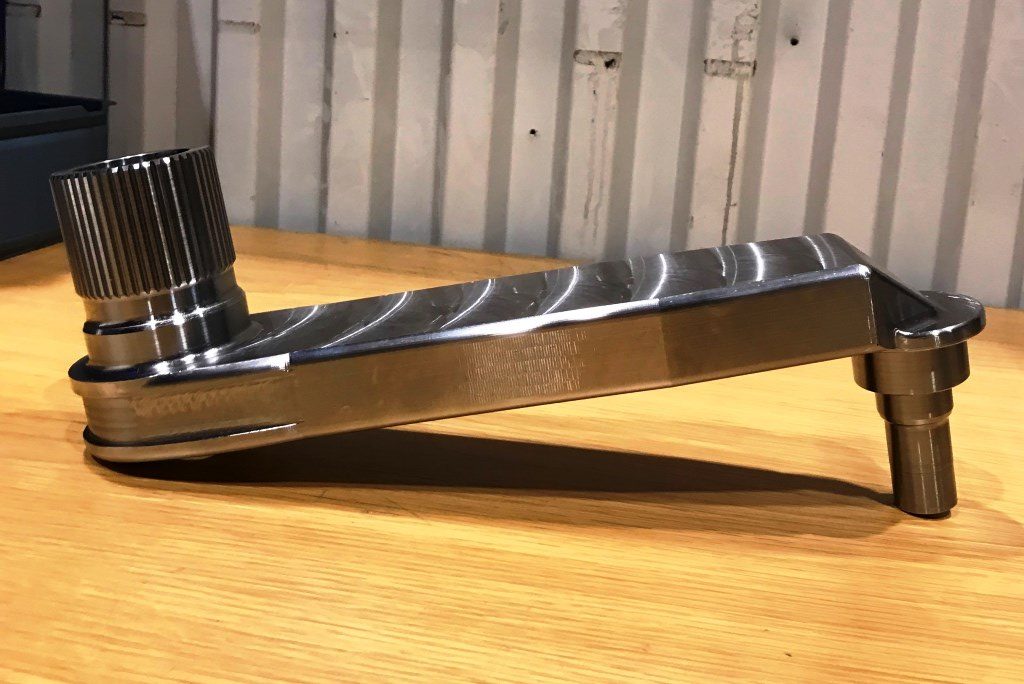

One of the greatest benefits of Additive Manufacturing is the short lead times. Björn Hellholm, head of Research and Development at BAE Systems Hägglunds explained: “If we take a large aluminum part as an example, it takes about 24 hours to print it, with a short subsequent processing time. If we had instead cast the same detail, it would have taken at least six months. The quality will be equal, if not better, with 3D printing.”

In early 2024, BAE Systems Hägglunds began development of a digital vehicle maintenance package for its customers. The package involves the use of additive manufacturing solutions, including a digital inventory library containing verified and tested spare parts recipes. This means that we can provide our customers with the ability to produce spare parts on-site and/or in the field. A process that focuses on the customer and their involvement.

“Building a common capability in this field is an important piece of the puzzle when it comes to creating security of supply in all levels of conflict. Additive Manufacturing provides us with the capability to manufacture spare parts when the ordinary supply chain can’t deliver. A collaboration between BAE Systems and Saab creates good conditions for maintaining availability of the armed forces’ material,” said Per Öster, Adviser to the Head of Defence Staff’s support unit, Swedish Armed Forces.

Both BAE Systems Hägglunds and Saab have several years of experience in the area of Additive Manufacturing.

“As companies, we bring different experiences and knowledge to the table, and the fact that we don’t have any competing products but have the same customer makes it easy to collaborate,” added Petter Bedoire, Chief Technology Officer at Saab.