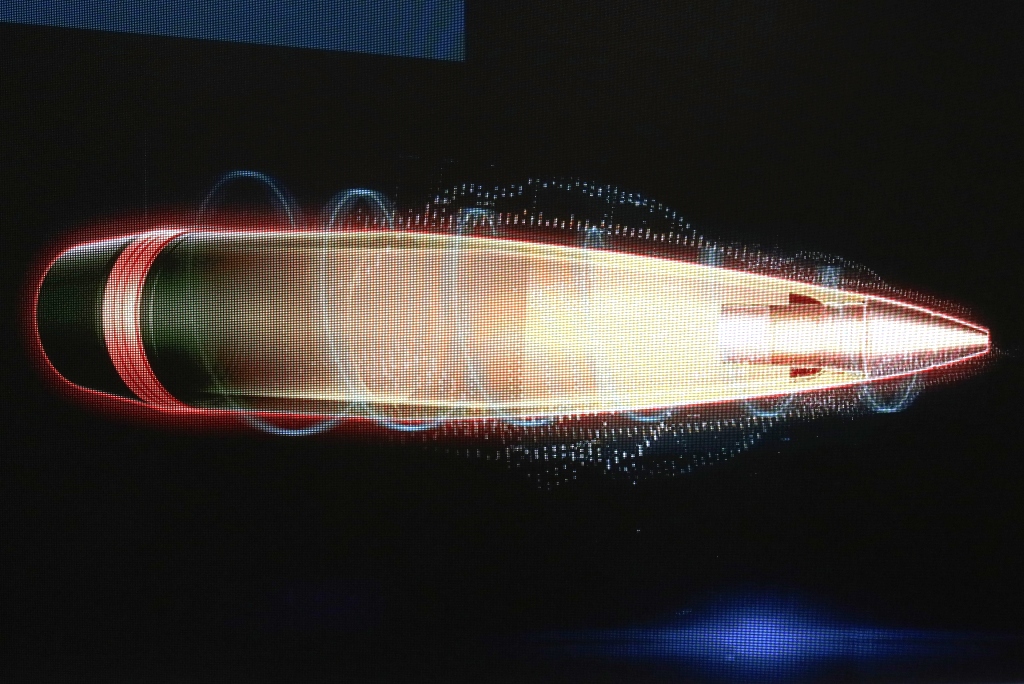

DSEI 2023 – BAE Systems NGAA future artillery munitions: better performances, maximum flexibility, easy to produce at lower costs

At DSEI 2023 BAE Systems unveiled its new NGAA, the acronym standing for Next Generation Adaptable Ammunition, this new round promising to revolutionise the world of 155 mm rounds addressing among other mass production issues, a key factor in today world

The Russia-Ukraine conflict highlighted the issue of ammunition stocks and of the limited production capacity by an industry tailored to a long peacetime period. BAE Systems launched a programme to develop its Next Generation Adaptable Ammunition, NGAA in short, that will address the production issue while also improving performances and growth potential, keeping also a close eye on compatibility and cost issues.

Steve Cordew, Business Development and Strategy Director and Gavin Crimmings, Head of Engineering, at BAE Systems Land UK, explained the key bullets of the new family of ammunition that in perspective will replace the ageing L15 family in UK service, while looking at a much larger market.

The initiative profits of recent successes on the national and export markets. The key production issue is dealt with thanks to a comprehensive approach that aims at allowing the use of less specialised materiel that can be used by non-defence related industry, converting those into mass ammunition production facilities when the need arises. This has also to involve the supply chain, therefore moving off from defence-specific materiel going to commercially available one is one of the key aspects.

“We will produce the ammunition body using selected commercial steel, moving away from the specialised defence steel used until now, which will allow us to buy it from a much bigger number of suppliers,” BAE Systems speakers explained. EDR On-Line understood that to get as close as possible to the characteristics of the steel used in current ammunition production BAE Systems engineers will apply some different manufacturing methods, namely in the heat treatments. Moreover the NGAA will feature a single shell body, compared to the different ones used nowadays in the L15 family, which will considerably ease production and increase commonality.

Energetic materiel will also be the subject of a revolution; melt-cast composite explosives have good safety and performance characteristics, however their production is difficult to be scaled up as it requires specific skills and equipment “We are moving towards resonance acoustic mixing, RAM in short,” the speakers said, “which is a much faster process, taking down production times from hours to minutes, which increases agility while reducing cost and waste, this technology being better suited for high volume production.” New chemistry is being developed and later this year new announcements will be made by BAE Systems in that field, the aim being to develop a national production capacity.

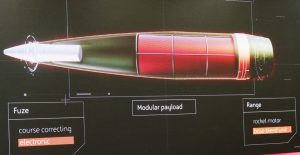

The most noble part in an artillery round is the fuze. Here too the NGAA programme adopts a disruptive approach, as it will abandon mechanic fuses in favour of an all electronic e-Fuze that adopts complex weapons technologies. This shift will allow BAE Systems to rely on a robust supply chain of off-the shelf components. The e-Fuze will also be scalable, and could be applied to other calibres, such as the naval 5-inch or 127 mm one

EDR On-Line understood the shell will be capable to host modular loads, the most obvious ones being the High Explosive (HE) one based on next generation explosive filling, and the advanced illuminating and smoke payloads, which will feature programmable outputs. The latter will leverage the most advanced solutions in terms of multispectral screening and light producing materiel, such as the New Generation Red Phosphorus.

Modularity will also be applied to the rage extenders, the standard boat tail being replaceable by a base bleed tail increasing range up to 40 km when fired from a 52 calibre barrel, up to a rocket assisted propulsion (RA) module that brings range at over 65 km.

The NGAA will be totally compatible with existing Course Correction fuzes, hence accuracy will be ensured even when using RAP.

The adoption of new materiel and production methods will allow, as anticipated, non defence-related production facility to manufacture these rounds, should the need arise, the switch from peacetime to wartime production being relatively short, the adoption of off-the shelf components also considerably reducing lead time.

As said, competitiveness is a key issue, BAE Systems aiming at a cost reduction between 50% and 75% in the round, however the e-Fuze will probably be cost-neutral according to information provided to EDR On-Line.

BAE Systems is not looking only at today issues, such as production and costs. Its NGAA also aims to be future-proof, payload modularity opening doors, the new round featuring a potential for a range of non-lethal end effects in the electronic warfare, communications and navigation fields, maxing the 155 mm artillery ammunition a fast deployable small uncrewed system, other even more innovative payloads being potentially developed.

How far away is the NGAA? “We plan to demonstrate it in late 2023,” the speakers announced, EDR On-Line understanding that the demo will encompass all the major elements of the new round.

Images courtesy BAE Systems