Boxer: a recovery module from FFG

The Boxer was definitely the armoured vehicle mostly represented at DSEI, as beside those exhibited at the KNDS/KMW stand and at the Rheinmetall one, a third 8×8 was exhibited at the FFG (Flensburger Fahrzeugbau Gesellschaft). The latter was carrying a new module, unveiled in London by the Flensburg-based company, aimed at adding the recovery capability to the Boxer family.

Itsdevelopment, entirely financed with company funds, started in mid 2017, when FFG identified a gap in the Boxer capabilities, and in one and a half years time the new module has been brought to prototype level. The system has already undergone company trials that involved also KMW, the company aiming at obtaining full qualification, FFG knowing well the qualification procedures having developed the Wiesent and Wiesent 2, based respectively on the Leopard 1 and Leopard 2 chassis.

The two-man crew access the module via a side hatch on the left of the module, the driver position remaining that typical of the Boxer, front right, with the powerpack on the left. Two side arms with hydraulic jacks and one 2.95 meters wide rear spade ensure maximum stability to the vehicle before using the different equipment fitted to the module. Hydraulic power is provided by an electro-hydraulic drive, which in turn is powered by a Lithium-Ion battery pack which is charged by the vehicle alternator. Batteries allow 3-4 hours of operation with the Boxer engine cut off.

At the rear, on the centreline, we find the pivoting crane which is fitted with a 5.3 meters long boom that can carry a lift up to 20 tonnes. Maximum elevation is 60° which gives a maximum lifting height of over 6 meters. Considering that the heaviest currently available module for the Boxer weighs 14 tonnes, the ARM (Armoured Recovery Module) can easily be used when changing in configuration are needed, powerpack replacement and other maintenance operations being also fully supported by the FFG-designed module. At the rear a 60 meters long kevlar cable can be used to extract a vehicle from problematic situations, the low-weight high-resistance cable with a 22 mm diameter being fitted to a hydraulic capstan with a pull force comprised between 0 and 200 kN. Both the crane and the winch can be operated at distance using a mobile console, or from inside the vehicle thanks to touch-screen displays.

Additional equipment can be fitted, i.e. lifting accessories, a cutting and welding station, as well as hydraulic and/or pneumatic power tools.

The two-man crew compartment is fitted with anti-mine seats and a CBRN protection system, add-on armour allowing to increase ballistic protection. The prototype seen at DSEI was fitted with a Kongsberg RCWS, installed on the right side just ahead of the crane.

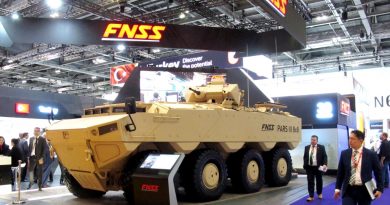

The ARM module is 7 meters long, 3 meters wide and 2.45 meters high (without the RCWS). FFG installed its module, painted green, onto a sand-painted Boxer chassis, the colour contrast showing well the modularity concept. Although not all nations have shown interest in the past for a wheeled recovery vehicle, something that remains difficult to understand, the FFG booth was visited by various military delegations of nations that are using or have selected the Boxer, who showed considerable interest. EDR On-Line understood that the company is further developing the concept, a crane with greater capability being one option for the future.

Photos by Paolo Valpolini