Increasing effectiveness and range: the new LU 220 HE 155 mm munition by Nexter Arrowtech

The advent of 52 calibre 155 mm artillery guns led to the development of a new generation of munitions that were able to fully exploit the increased range capability of those systems. In Europe then GIAT Industries munitions business unit developed the LU 211, which in 1999 was classified as “MUnitions à Risque Atténué” (MURAT, attenuated risk munitions) by the Armament Inspector for Powders and Explosives (IPE), the French National Explosive Safety Authority. That new artillery round was developed to maximise the range of the new Caesar 155/52 truck-mounted howitzer at that time under development by the same company and that would enter service with the French Army in 2008. To do so the shape of the round was different from that of older 155 mm munitions destined to 39 calibre howitzers, the more streamlined body giving a lower aerodynamic drag, hence a longer range, further enhanced by the longer barrel that allowed exploiting to the limit the pressure generated by the maximum charge. Then GIAT Industries also developed the insensitive explosive used in the LU 211 HE munition, named XF 13 333, the key element in the “muratisation” of that ammunition.

Compared to a typical COMP B explosive, a highly insensitive explosive has a lower efficiency in terms of energy, losing between 10 and 20% depending on various factors, among which the angle of the round when it hits the target. Further increasing the range and bringing back the terminal effect to that of the Comp B loaded LU 211 munitions was therefore the aim of what is now known as Nexter Arrowtech France.

The new ammunition development study is carried on within the framework of a research programme sponsored by the French DGA, the French Defence procurement and technology agency. The study phase is coming to an end and the LU 220, this the name of the new round, is currently rated at TRL 6. “We need to qualify it, and to submit it to all tests required by STANAGs,” a company source told EDR On-Line, one of those being STANAG 4439 “Policy for Introduction and Assessment of Insensitive Munitions”.

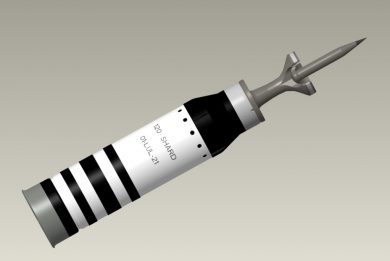

How to obtain two contradictory results, increasing range together with terminal effect? The company R&D decided to increase the munition dimensions while keeping the weight close to that of the LU 211. The LU 220 with fuse is 940 mm long, compared to the 867 mm of the LU 211, but remains fully compatible with the Caesar and the other 52 cal artillery systems, its mass being between 45 and 46 kg in the Base Bleed configuration, compared to the 43.9 kg of the in-service munition. The diameter being obviously the same, being imposed by the calibre, the extra 73 mm in length allows obtaining a better aspect ratio reducing the aerodynamic drag hence increasing the range. Moreover the higher volume of the bigger LU 220 allows for a higher amount of insensitive explosive to be loaded into the round, 11 kg compared to the 8.8 kg of the LU 211, a 25% increase that compensates the inherently reduced explosive power of the XF 13 333 versus the Comp B. Of course the increased weight has limited the range increase, however that decision was taken in full accordance with the French Defence authorities, the DGA and the Army technical services as well as the feedback provided by operational personnel, who clearly stated that priority one was the increase of the terminal effect on the target. Another plus of the LU 220 over the LU 211 is that the new munition is designed to accept deep intrusion fuses and can therefore be fitted with precision guidance fuses, as i.e. Northrop Grumman’s PGK (Precision Guidance Kit). Nexter signed an agreement with Northrop Grumman, the two companies working together to get ready to propose its new round on the export market fitted with the PGK, the compatibility with such type of fuse allowing of course customers to eventually chose other course correction fuses available on the market.

The first iteration of the LU 220 will be based on a conventional steel body providing a natural fragmentation effect. However Nexter Arrowtech is already looking at a further evolution, that will have a body obtained with 3D printing and will include preformed fragments. “Currently we manage the technology which is however not enough mature under many aspects, which leads to a cost per shell unacceptable on the market, we intend to pursue our goal in the future,” a company source told EDR On-Line. “As for the munition with the conventional shell, we intend to finalise its development in order to be able to propose our new ammunition to some selected customers, including the French Army, answering the request for conventional artillery munitions with a further extended range,” he added, underlining that tests were carried out in which the LU 220 reached 44 km, compared to the 40 km of the LU 211. This shows that even giving priority to the amount of explosive carried, hence the terminal effect, the better aerodynamics of the new round overcompensated the higher weight, allowing a +10% in range in the very first tests.

“The development study for the DGA is now finished, and we are awaiting the DGA to provide us reports on terminal effects,” a Nexter Arrowtech representative tells EDR On-Line, “and we are now aiming at launching as soon as possible a full development programme, full product availability being forecasted in 30 months time.”