Indirect fires: Rheinmetall details its latest solutions

At Eurosatory last June Rheinmetall unveiled its proposal for the German Zukünftiges System Indirektes Feuer mittlerer Reichweite (Future system Medium range indirect fire) programme, which aims at providing the Army with new wheeled long range howitzers to answer the Russian superiority in terms of indirect fires. Range comparison shows immediately the critical situation in which western armies find themselves in terms of tube artillery, the Russian 2S35 Koalitsiya-SV reaching over 70 km while the PzH2000, currently one of the most advanced western systems, fitted with a 52-calibre barrel, can shoot at slightly over 30 km using a boat tail munition, and short of 40 km using a base bleed round. The Russian attack against Ukraine of February 24th 2022 and the prolonged war that ensued has shown once again that in terms of casualties, indirect fires account for 70-80% of the total. Many armies, among which the German one, which were already considering to improve their artillery assets to fix this unbalance, have accelerated their programmes, while industry is actively proposing new solutions.

Rheinmetall’s roadmap in this field is clear and aims at increasing ranges exploiting new guns, new projectiles and new charges. Lethality, range, survivability, mobility, ammunition load, rate of fire, automation and ergonomics are all fields that need improvements in order to provide forces with effective systems, a reasonable growth potential being also a priority considering the need to evolve new systems in order to adapt them to new threats and operational scenarios. Beside the launching element, the gun/howitzer, Rheinmetall is also working on propellants and projectiles to increase ranges and effects. EDR On-Line was provided a full briefing on what the Düsseldorf-based group is developing in the artillery domain during the 20th edition of the Rheinmetall Defence Talks, which took place in Berlin 5-7 December 2022.

Truck mounted artillery, a stepped approach with more growth potential

Adopting a pragmatic approach, Rheinmetall decided avoiding to design a fully new product, and teamed with Elbit Systems of Israel, the latter having a new artillery system already in advanced stage of development. In April 2019 the Israeli Ministry of Defence signed a contract with Elbit Systems for the development of an “advanced artillery system to replace existing ones.” Known as Sigma, it is a truck-mounted and fully automated howitzer, which pre-series systems should be delivered soon, the IDF requirement being for over 100 guns.

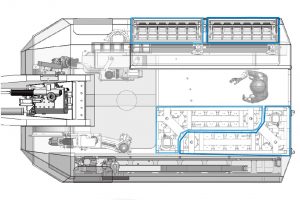

“Rheinmetall is ‘Europeanising’ it, integrating the RWM 155/52 mm elevating mass, the fire control computer, and installing the system on an HX3 10×10 RMMV truck, a demonstrator being expected to run in 2023,” Patrick Lenz, Vice President Business Development-Portfolio, Vehicle Systems Division told the audience. As anticipated, the new system will be fully automated, therefore the turret will be unmanned, and the two-man crew will carry out fire missions remaining in the truck protected cabin. The turret features an automatic loading system that operates with the barrel at any elevation angle, the manipulator allowing chambering and ramming ammunition and charges, a chain rammer being used. It is compatible with all projectiles designed according to the NATO JBMOU (Joint Ballistics Memorandum of Understanding) and with charges following the Modular Charge System (MCS) or Extended Range Charge (ERC) standards. A fuse setter ensures the ammunition being loaded to be programmed with the data provided by the fire control system. The setter is produced according to NATO AOP-22 (Allied Ordnance Publication) “Design Criteria and Test Methods for Inductive Setting of Electronic Projectile Fuzes” and allows the setting of all fuses designed to standard.

The turret contains 40 projectiles and 192 charges, allowing firing 80% of the rounds, that is 32, with 6th charge increment. If required to shoot at the same target, therefore without the need to modify the elevation, the autoloader allows a rate of fire of 8 rounds per minute. The truck-mounted turret can fire up to five rounds in Multiple Round Simultaneous Impact (MRSI) mode. Should the autoloader system fail, manual loading would allow half that rate of fire, the turret being accessible to the crew thanks to a corridor between the ammunition load, on the left side, and the charges, on the right. On both sides we find two magazines, two 20-round ones on the left and two 96-charges ones on the right; this ensures redundancy, each being fitted with its own e-motor, and should one of them fail the system would remain operational, albeit capable to conduct a reduced number of fire missions. Magazines are based on a Paternoster system, and feature a chain with 20 compartments hosting the rounds, the selected round being moved in front of the manipulator that grabs it and carries it to the breech. Charge magazines are conceptually similar, the right number of modules being loaded according to inputs coming from the fire control system. The autoloading system is currently undergoing qualification tests in Israel, Elbit Systems working together with Israel Defence Forces. Blow-off panels ensure any explosion would be directed outwards reducing the effects on the truck cabin hosting the crew. Should a customer require a higher number of rounds, an extra 10-15 munitions can be hosted in the turret in add-on racks, of course not in the automatic loading system. The new system maintains the through-loading capacity of the PzH 2000, which allows manually loading ammunition from outside, these being either used for immediate firing or stored in the magazine, an operation that can be carried out at a rate of 4 rounds per minute.

As said, the Rheinmetall version of the truck-mounted howitzer will be fitted with the company 155/52 mm elevating mass. “This is similar to that installed in the PzH2000 tracked self-propelled howitzer, however the cradle is different. Development firings will be carried out in early 2023, starting from firing from a stand and step by step reaching the full system firing test,” Patrick Lenz said.

Between the turret and the platform vehicle, Rheinmetall will install the Artillery Turret Interface, ATI in short, fitted with four hydraulically operated outriggers, the only hydraulic elements of the whole system. “These allow stabilising the system in order to permit shooting on all 360° without any limitation in terms of elevation and charge. Outriggers are extended in less than 20 seconds and retracted in about the same time; should the main system fail, the operation can be carried out using the truck APU (Auxiliary Power Unit) or finally it can be done manually, of course in a longer time,” Patrick Lenz explained. EDR On-Line understood that Rheinmetall is investigating the possibility of carrying out fire missions without the need of extending the outriggers, in a limited angle, around ±10° from the 12 o’clock position

The platform vehicle is the HX3 10×10, the biggest version of RMMV new line of trucks. The turret is located at the rear, over the three rear axles, which allows a good load distribution, the five-axle architecture ensuring good mobility, sufficient for a combat support system that does not need to follow combat vehicles in the worst mobility situations. “Two main reasons led to the selection of a truck rather than an armoured personnel carrier as the platform of choice: one was cost, the HX3 being around one third the price of an APC, while the second was growth potential,” Patrick Lenz stated. Not only the acquisition price of a truck is lower, but also its life-cycle cost is lesser, which is even more true if the Army deploying the system is already equipped with HX vehicles. In the current configuration the SP howitzer can carry an extra 5 tonnes, which provides flexibility in terms of add-on capacities to cope with evolving threats and scenarios.

One of the future developments was already visible in Paris as a mock-up, as the turret was fitted with a 60-calibre gun currently under development by Rheinmetall in its Unterlüß factory. The new gun has not only a longer barrel but also a bigger chamber volume, comparable to that of the US ERCA (Extended Range Cannon Artillery), and a fully redesigned muzzle brake. Beside the L60 the German group is also developing the L52A1, which allows a higher chamber pressure, both solutions increasing the range. That said, forces in the turret will be very similar and the rate of fire will also be the same of current systems.

New propellant key to improve range

Having a long-barrel system to shoot a projectile is not enough, the energy the latter acquires during its travel within the barrel being provided by the propellant charge. Improvements in this field are ensured by Nitrochemie, the company jointly owned by Rheinmetall and RUAG and specialized in high-performance propellants. One of the key elements in the group evolution towards longer ranges is the Extended Range Charge, ERC in short.

“Its development started five years ago and the ERC has reached a relative high level of maturity,” Pascal Schreyer, Senior Vice President Sales & Marketing Propulsion Systems at Nitrochemie explained at the Berlin event. EDR On-Line understood that the ERC is now offered for in-service ammunition and in-service platforms, so both can now be qualified with the ECR. According to information provided, the ERC can increase the effective range of in service ammunition (BT and BB) and new ammunition (RAP, Rocket Assisted Projectile, and V-LAP) by 10% to 20%, increasing muzzle velocity while remaining within pressure limits of current guns, as it is compliant with the system Permissible Maximum Pressure (PMP) limit imposed by STANAG 4110. This ensures that barrel wear and system stability are respected. The ERC comes in a single piece charge, as it aims at maximum range, and its ballistic performances were proven in 2019-2022 on several platforms and in different firing ranges, with two firing campaigns in Alkantpan, South Africa, two in Yuma, United States, as well as other in Northern Europe.

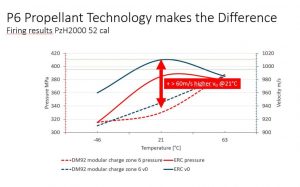

“The range increase can be exploited either to reach targets at longer distances, or to compensate the range loss generated by the adoption of course corrected fuses (CCF), which increase accuracy at the cost of a range reduction of around 10%,” Pascal Schreyer said, adding that “a new propellant technology was key in developing the ERC. Usual propellants employed in available modular charges have a near-linear increase in velocity and pressure along with temperature increase.

The ERC exploits a novel propellant developed by Nitrochemie, known as P6, which is a triple-base propellant that comes from a solvent less production, and is surface treated. “The P6 allows reaching peak performances at operational temperatures, around 21°C, hence increasing the overall system performances in the mostly used temperature range,” Pascal Schreyer said. As an example, considering the PzH 2000, at standard temperature the pressure is increased from around 330 to over 380 MPa compared to the DM92 modular charge Zone 6, and muzzle velocity is increased by nearly 70 m/s, from 945 to 1.015 m/s, according to the graphic provided.

Two different versions of the ERC are currently available, one for 155/39 mm and the other for 155/52 mm systems. Both have a proof pressure of 395 MPa and can be used in the –46/+63 °C range temperature, however their dimensions and weight differ, that for L39 guns being 780 mm long with a 13 kg weight while that for L52 systems is 960 mm long and weighs 16 kg, muzzle velocities being obviously different, over 900 m/s for shorter barrels and over 1,010 m/s for longer ones. Until now ERC developments were aimed at full-bore ammunition, however Rheinmetall is ready to develop a specific charge for subcalibre ammunition, should a customer require it.

New ammunition to deliver optimal terminal effect at longer ranges

“Today we have a BT projectile known as DM121 in Germany and M1712 in the Netherlands. The latter can be transformed in the M1711 that features a base bleed add-on allowing it to reach around 40 km when fired from the 52-caliber gun of the PzH 2000. We then have the V-LAP projectile, a smart solution that combines base bleed and rocket assisted propulsion, these working just at the right time. This solution allows to have more explosive than a RAP projectile, while obviously less than a standard one,” Dr. Christian von Hörsten, Head of Department, Development Artillery and Launcher Ammunition, Business Unit Weapon & Munition, told the audience adding that the V-LAP demonstrated in numerous tests its capacity to reach 54 km using the DM92 modular charge system.

Stepping from today solutions to near future indirect fire capability, this at Rheinmetall is represented by the use of the ERC, which as previously said allows a 10-20% range increase. These performances were tested and verified back in 2019 using a PzH 2000 howitzer.

A mid-term solution is offered by the L52A1 gun, which is an optimisation of the currently available gun installed on the PzH 2000, which can be qualified in shorter times compared to a fully new weapon. It uses the same barrel, the same breech and the same sealing system, however it has a bigger chamber volume and the chamber pressure is increased

The long term solution obviously comes with the L60 gun and new projectiles, which are being developed to answer the aforementioned Future system Medium range indirect fire programme which requirements calls for a 75 km range with conventional ammunition. “As this figure is for non guided ammunition, we added some range to compensate course correction fuses,” Dr. von Hörsten explains. The 82 km range will be reached using a V-LAP projectile, which EDR On-Line understood being a new development of currently available rounds that will maintain the same outer dimensions and weight, 43.5 kg, to be JMOU compatible, but will be hardened to accept higher pressure levels.

“The V-LAP carries around 4 kg of explosive, however we are working on pre-fragmented designs that will increase lethality,” he added. As part of its ammunition development programme Rheinmetall is also working on a new driving band, which was tested in 2021 shooting from a PzH 2000, using modified charges. The charge system for the L60 will adopt a stub case, to deal with higher chamber pressures, and the primer will be screwed into the stub case and not located in the breech. reaching a muzzle velocity of 1,144 m/s. First trials are expected to take place in early 2023.

| Today | Near future | Mid term | Long term | |

| L52 / MCS-DM92 | L52 / ERC | I52A1 / ERC | L60 / ERC | |

| Boat Tail (BT) | 30 km | 36 km | 39 km | 48 km |

| Base Bleed (BB) | 40 km | 46 km | 52 km | 64 km |

| Velocity-enhanced Long-range Artillery Projectile (V-LAP) | 54 km | 63 km | 68 km | 82 km |

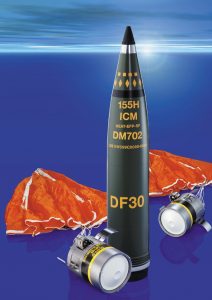

Beside the work being done on new projectiles and charges, Rheinmetall is also launching an upgrade programme concerning its SMArt 155 (Suchzünder Munition für die Artillerie 155Ammunition, search-used ammunition for artillery) currently in service with Germany,Greece, Switzerland and Australia, and qualified for use in the United States.

Developed in the late 1980s by GIWS (Gesellschaft für Intelligente WirkSysteme) a joint venture between Rheinmetall and Diehl Defence, each round contains two submunitions that are released over the target area, their seeker sensing tanks and armoured vehicles and attacking them from above. Used in combat in 2022 it is therefore now TRL 9. To solve obsolescence problems GIWS has just started the upgrade programme; “in 2025 we will get to the proof at components stage, production start being planned for 2027,” Dr. von Hörsten said. However work will not be limited to replacing obsolete elements of the ammunition. “Here too we are looking for extended range, the round reaching currently 22 km with an L39 barrel and 26 km with an L52. The programme is carried out in partnership with General Dynamics Ordnance and Tactical Systems in the United States. We developed a new outer shell with Base Bleed, containing the same submunitions,” he added. To test the range issue, shells with BB and inert mass were fired in September 2021 and August 2022; the first tests carried out from an L39 system achieved a 27 km range, while the following one was done from the ERCA prototype with the L58 barrel, with reduced charge and lower elevation, reaching over 38 km, maximum predicted range being 48 km with a muzzle velocity of 1,054 m/s. The new round is fully JBMOOU compliant, the programme running under the C-DAEM (Cannon-Delivered Area Effects Munition), GD OTS being the prime. It also features a new lightweight aerodynamically optimised ogive which reduces drag, furthering the base bleed effect. A US decision is awaited before moving to the next development phase.

Photos and images courtesy Elbit Systems, Rheinmetall and P. Valpolini