Killing enemy drones with a kinetic energy UAS; MARSS unveils its Interceptor

How to kill an incoming UAV reducing to a minimum the risk of collateral damages, a key capability especially when operating in urban areas? At the World Defense Show in Riyadh the MARSS R&D team unveiled its Interceptor, a small UAV-killer that employs its kinetic energy to neutralise the opponent.

In the past, drones have sometime been destroyed using surface-to-air missiles when soft-kill measures proved insufficient, however an explosion over an urban area is unacceptable. And in the years to come a hard-kill solution might well become the standard, as killer-drones might become more and more autonomous, hence disrupting their data link with the ground control station might become a useless solution. The Monaco-based company with principal operations in the UK keeps an R&D and production unit in Saudi Arabia, drone attacks being one of the critical issues in the region.

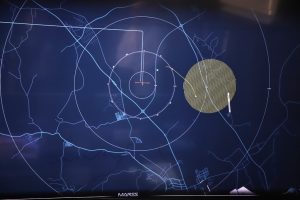

With an already good footprint in the Middle East as far as command and control is concerned, MARSS developed the NiDAR C-UAS long range surveillance system capable to protect high value maritime and land-based assets from air, surface and underwater approaches, the company used to team with soft and hard kill effectors producers to provide its customers full capability systems.

On Day 2 of the Riyadh exhibition the company briefed the press on its new MARSS Interceptor. This is a high speed drone, it flies up to 80 m/s, which means 155 knots or 288 km/h, around the double speed of Category 1 and Category 2 drones that MARSS intends to challenge with its new product.

The aircraft has an aerodynamic fuselage with a 0.9 meters wingspan mid wing, and four ducted rotors/propellers activated by electric motors. The Interceptor takes-off vertically and then rotates becoming a wing-lift flying machine, rotors becoming now propellers and accelerating the aircraft. The two ducted propellers at the extremities of the wing are smaller compared to those installed on top and underneath the air vehicle, when this flies as a plane.

Main ducted fans provide the principal thrust, while the two at wing extremities contribute to the thrust but should be mainly used in differential manner to steer the air vehicle, hence their smaller dimensions should make control easier. The structure was kept as light as possible, most part being made of carbon fibre with the insertion of titanium elements. The overall drone weighs less than 10 kg, which helps in ensuring maximum speed capacity,

“The Interceptor exploits kinetic energy to down its opponent, hence titanium is used to reinforce the forward part of the fuselage, inserts being also present in the wing leading edge and in the front part of the nacelles containing the propellers,” Johannes Pinl, the Austrian founder and CEO of MARSS explains, underlining that ducted fans are of proprietary design. Differential rotation speed of the rotors/propellers allow the interceptor to manoeuvre up to 4 g, the Interceptor being able to engage dogfight at altitudes of over 2 km. The drone-killer is fitted with an Imaging InfraRed sensor in the nose, which ensures maximum accuracy in the last phase of the attack thanks to IIR Artificial Intelligence-based video analysis, the Interceptor being designed to hit the enemy drone from underneath or in a frontal confrontation. “Against Class 1 targets the Interceptor would usually survive and be capable to reiterate the mission against another UAV,” Stephen Scott, the company Head of the Research and Development (Defence), tells EDR On-Line, adding that in normal circumstances the hit on a Class 2 airframe would cause the loss of the Interceptor.

A data-link is installed to allow controlling the UAV, however usually the mission is carried out autonomously. Artificial Intelligence and Machine-Learning algorithms used in the NiDAR together with the capacity of sensing the enemy drone, maximise the kill probability, which is estimated at around 90% at the maximum engagement range of 5 km. We must however consider that if it misses the target, the Interceptor can manoeuvre and reiterate the attack, which further increases the Pk.

“Cost per intercept is an issue,” Stephen Scott underlines, “and the estimated cost of a Short Range Air Defence Missile is between 150,000 and 200,000 US$, while we are at about one fifth of that value, and considering that a single Interceptor can eventually kill three Class 1 enemy drones, the saving might be even higher.”

The MARSS Interceptor is launched by a box-like system, visible in mock-up version at the show, that can be easily installed over a light vehicle. The launcher is raised in vertical position, hence after take-off the Interceptor will be able to steer in horizontal flight mode in any direction, according to data provided by the command and control system. The latter can control up to 12 Interceptors, each of them being able to kill up to 3 Class 1 drones. “Launchers are not only boxes,” Johannes Pinl says, explaining that the they all also carry out all pre-flight checks autonomously, adding that the dimensions should be reduced adopting some solutions already identified. He also underlines that the command and control system takes in count the collateral damage problem, ensuring that the killing action takes place over areas where debris have minimal impact. Should the situation change, a data link allows to update the information received by the Interceptors before take-off. Ideally in urban areas launchers would be installed on top of buildings, as it would be for sensors. A typical battery will field six vertical launchers

A rapid development programme carried out in around nine months, the MARSS Interceptor should reach its Initial Operational Capability in Q1 2023. So far it has been tested in open fields, worst case situations expecting it in the coming months in order to analyse all possible situations. Designed and manufactured in Saudi Arabia, that EDR On-Line understood should be the launch customer, the system is obviously offered to other nations, in the Middle East as well as in other geographical areas. “We are designing our production to be able to produce up to 200 Interceptors per year,” the CEO says, a production line in Europe being forecasted should customers materialise in that region.

The current version is however only a starter. “We are already considering a smaller and a bigger version,” Johannes Pinls tells EDR On-Line, “the smaller being the first that will be developed.” Elaborating on this concept, the MARSS CEO explains that ideally those will be installed on armoured vehicles to provide protection against killer-drones, a solution similar to that used for smoke grenade launchers, but with bigger tubes, being an option. The reduced scale version of the Interceptor will have a reduced wingspan, and will probably feature only three ducted fans. As for the bigger one, here MARSS aims producing a multirole aircraft, that in the C-UAS role will be able to confront Class 3 drones. However to do so kinetic energy is not a solution, according to Johannes Pinls, therefore the company designers intend exploiting the miniaturisation of EW solution and especially that of High Power Microwave systems, the Interceptor allowing to approach the enemy drone at distances compatible with the RF energy generated by the effector to neutralise the incoming threat.

Photos by MARSS and P. Valpolini, viewgraph courtesy MARSS