More on Rheinmetall tank guns and ammunition evolution

By Paolo Valpolini

Following the recent briefing by Christoph Henselmann, Senior Vice-President and Head of Portfolio Tank Main Armament on the future of main battle tanks armament EDR On-Line gained additional information to better understand some of the topics that were discussed during the Rheinmetall Defence Talks (to read that article please click HERE).

Let’s start from the 120 mm ammunition. The DM73 is fully finalised and the new APFSDS round has started qualification firing sequences at WehrTechnische Dienststelle 91 (WTD 91) in Meppen, the Bundeswehr Technical Centre for Weapons and Ammunition depending from BAAINBw, the Federal Office of Bundeswehr Equipment.

“The DM73 maintains exactly the same penetrator of the DM63 currently in service,” Mr. Henselmann explains, “we worked only on the propulsion system, mainly to increase the combat range rather than to increase performances, as requested by the customer.” Modifying the combustible case and the type of propellant, Rheinmetall engineers and scientists working at the Unterlüss facility managed to start exploiting part of the increased admissible pressure of the new L55A1 120 mm smoothbore gun, the round having an 8% extra energy compared to the older round. To withstand the increased pressure the metallic stub case of the new round is produced in a more resistant materiel. The round is currently undergoing thorough testing by the Bundeswehr including a planned firing at very long distances for research purposes. Qualification is expected to be concluded by year-end, allowing customers equipped with Leopard 2A7V MBTs to exploit the performances of the new round. “As the projectile remains the same, we offer to our customers who have in stock numbers of DM63 rounds to upgrade those to the new standard, keeping the flight projectile, penetrator and sabot, and replacing the propulsion components,” Henselmann says.

Switching to the newest 120 mm round under development, the KE2020Neo, this is a completely new development, this ammunition aiming at fully exploiting the increase of 28 MPa of chamber Extreme Service Condition Pressure allowed by the L55A1 gun. “We started working on a new penetrator design since 2018,” Christoph Henselmann says, “and we are advancing in experimental firings at our Unterlüss range,” adding that the co-location of the R&D, the production and the range on the same premises allows for a very short modification cycle when some adaptations are needed.

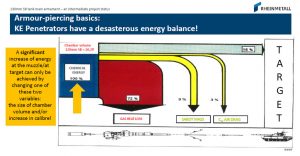

Talking about penetrators, EDR On-Line asked Mr. Henselmann to elaborate more on a slide shown in his last briefing, where the loss of energy from the chemical one generated in the chamber until the kinetic one reaching the target was depicted. Around 3% of the energy is lost due to the aerodynamic drag, the smallest reduction compared to those caused by the sabot and, mostly, by the gas heat dispersion. “To reduce the drag we should increase the length/diameter ratio, but our experiments have shown that increasing that ratio leads to lesser performances against explosive reactive armour. We must produce a penetrator capable to cope with a set of different targets, hence we must adopt a compromise, and we therefore consider the effectiveness against such targets the real driver, rather than looking for a marginal aerodynamic improvement.”

A loss of around 9% is due to the sabot mass, as the sabot has to be accelerated by the gas generated in the chamber, but once the round leaves the muzzle the sabot is discarded and will not bring any energy to the target, as it will fall just ahead of the tank. “There are two ways to try to reduce that “parasitic weight”, one is to produce a sabot in a lighter material, the other to optimise its design,” the Head of Rheinmetall’s Portfolio Tank Main Armament explains. New material for sabots is being developed in the United States for Depleted Uranium rounds, but apparently many hurdles have yet to be overcome. “We are looking at a new improved sabot design,” he says without revealing details, “the other challenge being to cope with the increased pressure.” As for the gas heat loss, “this would require the development of a new specific steel, but for the time being our scientists do not consider this a viable path.” Therefore increasing pressure, hence muzzle speed, and consequently speed and energy on the target, and improving penetrator’s performances, remain the only solution.

“In the development of our new 120 mm round we fully exploit the tools provided by our excellent simulation department, which brings with it decade long experience hence a huge data base of firing results,” he stresses, adding that both in the development of the KE2020Neo and the 130 mm results provided by the simulation tool were pretty close to those experienced during live firing. “This allows us to considerably reduce firing sessions, hence time and cost, however live firing remains a must when we need to confirm the development work.” According to Christoph Henselmann to have a minimum statistic base 15-20 rounds of the same design must be fired, and the whole development work can see an iteration development process that brings to up to 20-25 different designs to be tested, which means 400-500 firings. Both KE2020Neo and 130 mm rounds are being tested against different types of NATO ballistic targets representing respectively the latest versions of T-72, T-80 and T-90 Russian main battle tanks, no equivalent target existing yet for the T-14 Armata, as western intelligence has not yet acquired enough information on its armour package. The firing path at Unterlüss allows to reach a maximum of 2,000 meters distance, hence for longer range firing tests will be carried out at the WTD91. “Usually we fire at 2,000 meters for accuracy tests, while for effectiveness tests we fire at shorter distances, reducing the propellant charge to simulate longer ranges, in order to be sure to hit the very expensive target in the right place,” Henselmann explains.

Rheinmetall is fully involved in the KE2020Neo development, the aim being to freeze the configuration in early 2023, two years from now, in order to complete company tests within that year to start government qualifications in late 2023, at that time the round adopting a “DM” naming. “This will be a wholly new round, so we consider that qualification tests will require 1.5-2 years to be completed, and we look forward starting series production in late 2025,” Christoph Henselmann states.

In the mean time work on the 130 mm gun system, that is the gun itself, the automatic loader, and the ammunition will continue. EDR On-Line understood that the aspect ratio of the 130 mm penetrator will remain similar, length an diameter being of course greater than in the 120 mm round, increasing weight which linearly increases kinetic energy. But the major energy increase will come from the speed, the chamber volume increased by 50% compared to the 120 mm gun allowing for greater pressure, nearly 15% more, which should result in an undisclosed higher muzzle velocity, speed increases counting in quadratic manner in the Ke = ½ m.v2 energy equation.

The speed increase must be considered when we take in count the greater ranges required by the customer, 4-4.5 km; one key parameter is the time of flight, as MBTs often fire against other MBTs that might well be on the move, hence the longer the range, the higher the time on target, the least predictable the future position of the target. Considering a target travelling perpendicularly at 30 km/h, this means slightly over 8 m/s, and with current rounds flying at an average speed of 1,500 m/s a target at 2 km is reached in around 1.3 seconds, allowing it to move 11 meters from its original location, something manageable in terms of targeting considering that the T-72 MBT hull is slightly less than 7 meters long. If we more than double the range, the distance travelled by the target will become much higher, as not only the distance is greater but also the round velocity will decrease due to the drag, making things more complicated, not to mention possible effects due i.e. to cross, wind which increase with the time of flight. “I think we will have to consider up to which distance a tank gun can really be effective against a moving target, and when a missile must come into play,” Christoph Henselmann says, “which is something that applies perfectly to the Main Ground Combat System, as this will be a system of systems, made of different platforms, and it will allow the military to chose the right effector for the right range and the right target,” he concludes.

Photos and images courtesy Rheinmetall