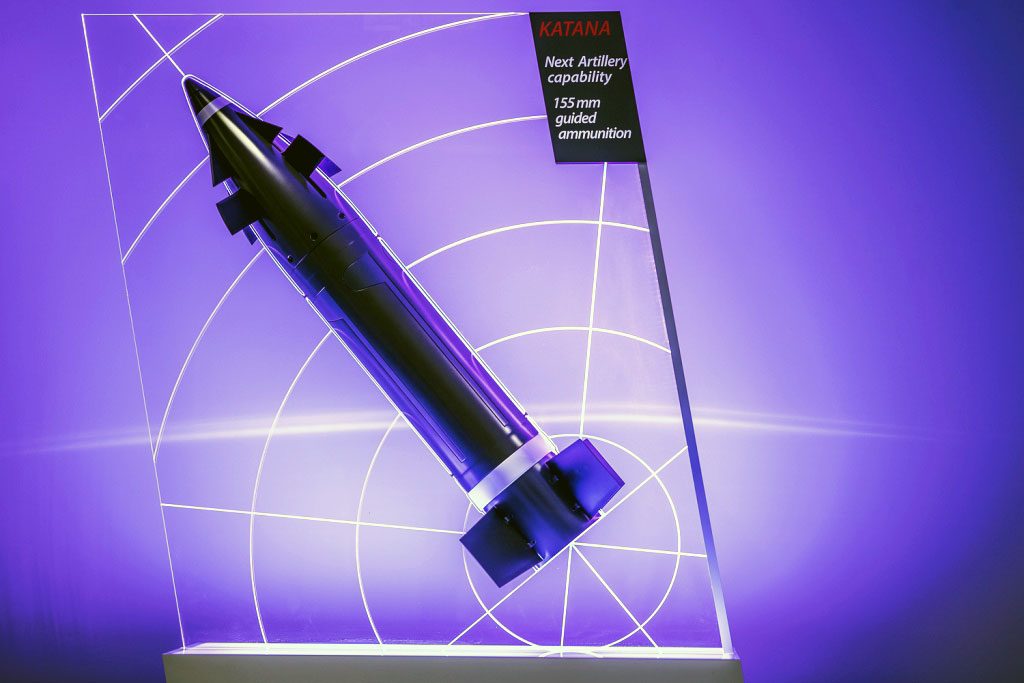

Nexter Arrowtech: the Katana 155 mm guided munition programme status

Increasing accuracy has always been the artilleryman dream, and it has become even more so since collateral damages have become a key issue. In the past years numerous solutions were developed, with different costs, performances, and operational constraints. Today Nexter Arrowtech inherits the developments carried out within the company munition business in the last few years. Among currently available systems we find at the lower step of the podium the Spacido 1D, a one-dimension course correction fuse capable to consistently increase range accuracy by a factor of 4 at long distance, according to Nexter. On the second step we find the Bonus Mk2 155 mm round, a fire-and-forget munition that deploys over the target area two sensor-fused attack modules with IR signature and 3D dimensions detectors, capable to carry out top-attacks against armoured vehicles and main battle tanks. The first step is still void, but will not remain so for long; unveiled in 2018, the Katana full-calibre 155 mm guided munition aims to climb soon on that podium. Designed for 52 calibre artillery systems, in its Base Bleed configuration it can exceed the 45 km mark with Top Charge Module Zone 6, ensuring a CEP (Circular Error Probable) of less than 10 meters. Its guidance system is based on an IMU/GNSS module, a fuse with impact, delay and height of burst modes triggering the warhead, the latter being loaded with more than 6 kg of XF 13 333 insensitive explosive.

“Katana is a key development for Nexter Arrowtech,” a company source tells EDR On-Line, “and we aim reaching TRL 6 [1] within 2023.” Despite the pandemic, the programme follows the scheduled timeline, its development being carried out according to the AGILE methodology, which is being used also for the development of the company SHARD 120 mm APFSDS tank ammunition. “We have a team of 30 skilled engineers who work in our Bourges facility on the Katana programme,” the source explains. Part of those engineers have been purposely hired, especially those specialised in guidance matters, a specialty that had to be re-acquired in-house as the last developments in that field date back to the 1980s, that expertise having therefore being lost. The AGILE system is based on a series of loops, the company discussing with the customer a certain level of requirement, which leads to a series of simulations and then of live firing trials. A comparison between performances obtained and those required by the customer is then carried out, a product maturity review then following, a case file being finally delivered to the customer who gives his comments. “This methodology is very similar to that used by software developers, and it allows reducing development costs, number of cycles and time to market,” Nexter Arrowtech experts point out. Currently the development process has already seen two iterations. Asked about the main hurdles to overcome, the Nexter speaker told EDR On-Line that mechanical dimensioning as well as the design of the rear empennage were quite tough, as well as the validation of the guidance system in close-loop.

The Katana programme is developed mostly on company funds, although the French DGA, the French Defence procurement and technology agency, filed a support contract to the company for a small number of ammunition. Once reached TRL 7 in 2023, Nexter Arrowtech will be ready to qualify the new product, a number of potential customers already lining up showing their interest for this new guided munition. A key advantage of the Katana 155 mm is to be ITAR-free, the manufacturer being also ready to provide the user keys to the client nation. “The Katana was developed as a modular system, therefore it can accept a number of modules that might be produced in partner nations,” EDR On-Line is told, a peculiarity that might favour the Nexter munition on the export market, especially in those countries were direct offsets are required. Another advantage over competing bestseller guided munition in the same calibre, according to Nexter Arrowtech experts, is the amount of insensitive explosive contained in the shell, which according to information available should be over than 30% higher.

The

munition currently under development is the Katana Mark I, which employs a

number of off-the-shelf subsystems that are being made compatible with

accelerations typical of an artillery grenade, however a further development

will bring to the Katana Mark II, which will feature all purposely-developed

components; how much this will also allow to improve performances remains to be

seen.

In December 2020 Nexter performed the first open

loop firings; this means that the test instrumentation verified that the system

received the right guidance signals, but no actions were taken to actually

guide the munition. “In July 2021 the first guided firings took place, and by

2022 we plan to carry out the first closed-loop firings, in which the munition

will autonomously guide itself on the planned coordinates,” our speaker says,

adding that most of those trials are carried out at the Bofors Test Centre in

Karlskoga, Sweden, over 200 km west of Stockholm. That test range cannot

however be used for firings at the maximum distance, the only range that can

probably support such activity both in terms of dimensions and instrumentation

being that in Vidsel, some 700 km north of Stockholm, which is operated by the Swedish Defence Materiel Administration.

These tests should lead to the completion of the development programme, with

the last firings in 2023 bringing the Katana to the desired TRL 7. EDR On-Line

understands that full development will be launched as soon as a firm contract

will be obtained, which will allow the company to fully qualify the new product

and launch the low rate initial production. No indication was given on the time-to-market

needed once this process will be started.

Photos courtesy Nexter Arrowtech

[1] According to the Technical Readiness Levels table, TRL 6 means “ technology demonstrated in relevant environment ”