IDEF 2023 – Otokar unveils its Alpar 15 tonnes unmanned ground vehicle

Otokar, the Koç Group company specialised in commercial and military vehicles, exhibited for the first time its Alpar unmanned ground vehicle at IDEF 2023

With a gross vehicle weight of 15 tonnes, 3 tonnes being the payload, the Alpar is considered a heavy unmanned ground vehicle (UGV) according to Turkish nomenclature, while it would be a medium UGV in the US and Europe, the Alpar is the very first unmanned vehicle developed by the Istanbul-headquartered company. The Otokar production facility in Sakarya produces both tracked and wheeled vehicles, but the choice for the first unmanned vehicle the company developed went to a tracked solution. Tracked vehicles have less terrain problems, Serdar Görgüç, Otokar General Manager explained to EDR On-Line.

The Alpar chassis is very much tank-like, with the rear part slightly higher to host the powerpack. It is 6.25 metres long, 2.75 metres wide and 1.5 metres high, ground clearance being 450 mm. Propulsion is provided by a serial hybrid powerpack; two 80 kW electric motors working at a nominal tension of 630 V (maximum 750 V) activate the rear sprockets, powered by two Li-İon NMC battery packs providing 69 kW each. A 180 kW diesel range extender reloads the batteries; these are located at the front of the vehicle, each pack weighing 480 kg, the UGV having space for two more packs, their shape having been designed according to the vehicle internal volume. Should this option be finalised, it is clear that the payload would be reduced by nearly one third. A quick battery packs change system was adopted, however specialised personnel is required considering also the high voltage involved.

The diesel engine, the cooling system and the two electric motors are located at the rear, in a layout that resembles pretty much to a standard main battle tank powerpack, this layout allowing balancing the weight of the batteries.

The Alpar features a six road wheels running gear with rear sprocket and front idler, suspensions being of the torsion bar type with hydraulic damper, an automatic system ensuring optimal track tensioning. Currently the Alpar is fitted with steel tracks but these can be replaced by Soucy rubber tracks, the UGV having been designed to be compatible with M113 rubber tracks without modification, only the automatic tensioner requiring some adjustments. These would provide advantages in term of reduced vibrations and noise, the latter being key when the Alpar will move in silent mode, with the diesel extender shut down, the vehicle being able to travel for some 50 km only on batteries, while the overall range of the vehicle is of 550 km.

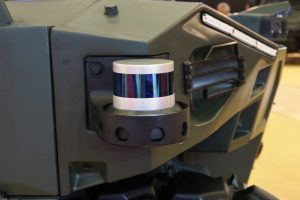

Currently the Alpar is teleoperated up to a distance of 5 km using radiofrequency signals, the range being extended if GSM communications are used. Its sensor suite dedicated to autonomous movements includes four 3D LIDARs, installed at teach corner of the chassis, two radars, one front and one rear, and four groups of day/night cameras providing a 360° coverage. These provide information to the control computer which is the brain of the system. Full autonomy is still far away, but the Alpar is capable of waypoint navigation, to conduct convoy missions exploiting its platooning and follow–me functions, and return home. Currently the crew is made of two operators, one dedicated to the chassis and one to the payload, but in the future, with the increase in autonomy manpower should be reduced, one control station being probably able to monitor more than one vehicle at the same time.

Otokar produced two technology demonstrator, one for the reconnaissance role, exhibited at IDEF 2023, and one in antitank configuration. Other version such as counter-UAS, radio relay, logistic resupply, and loitering munitions carrier are already being envisaged. The version seen in Istanbul was fitted with an Aselsan RCWS, a mast carrying optronic sensors being installed at the rear-right side of the chassis, exploiting the room available. The antitank version is fitted with a medium calibre Aselsan turret carrying two antitank missiles on its right side. Both vehicles are fitted with a forward ramp that allows a mini-UGV to be deployed and recovered, this being used mostly for stealthy recce missions at close contact. For those versions which missions require the vehicle to remain static for long periods of time while using their payloads, Otokar is considering installing on the Alpar energy harvesting systems such as solar panels, to silently reload batteries.

EDR On-Line understood that the Turkish Land Forces are close to launch a Request for Information for light and medium UGVs, therefore the Otokar effort, which is entirely conducted on company funds, is looking further down the time axis. The development plan might see at a certain point the advent of a wheeled platform; the company General Manager pointed out that Line Replaceable Units not only have been positioned in order to allow ease of maintenance, but are also independent and could be easily reused on a wheeled UGV.

Autonomy on land vehicles is definitely less advanced than that in the air, not only in terms of technology but also in terms of operational concepts, most armies being currently working in order to find out which are the missions for which UGVs would really provide key advantages.

Otokar has launched a five-year development programme for which it has reserved a portion of its research and development budget and selected a dedicated workforce to carry out the plan.

“There is a lot of work to do on Artificial Intelligence, and we have started a tough technological journey,” Mr. Görgüç concluded, already thinking of an Alpar operating as a wingman for a Tulpar infantry fighting vehicle.

Photos and images courtesy Otokar and P. Valpolini