DSEI 2023 – Rheinmetall exhibits its ADW based on top-attack SMArt 155 munition

With the comeback of a Cold War-like scenarios the defence industrial complex looks ahead on technologies but also, sometimes, looks back at old ideas. It is the case of the ADW, for Area Defence Weapon, exhibited at DSEI 2023 by Rheinmetall, a reactive mine based on the top-attack SMArt 155 munition

The Düsseldorf-based defense company Rheinmetall has apparently resumed work on a barrier concept that was first developed in the 1990s. The group publicly exhibited a model of the so-called Area Defense Weapon (ADW) for the first time as part of RüNET 2023, which took place in Koblenz on August 30th and 31st, 2023.

Towards the end of the Cold War the German Army was looking for a barrier concept to stop the mass of Soviet and Warsaw Pact tanks that might have attacked its borders, the main potential tank playgrounds being the Fulda Gap and the northern German planes. Beside standard antitank minefields, airmobile formations capable to funnel Red Army Operational Manoeuvre Groups into combat helicopter killing grounds, the idea of a barrier made of smart land-based mines able to attack the weakest point of an MBT, the top, started to appear. Nothing came to fruition, and the concept never became a product, financing being stopped in the late 1990’s when other types of missions became the bread and butter of most western land forces.

Since February 24th, 2022, things have consistently changed, and old ideas come back on the computer screen. It is the case of the ADW that is being developed by Rheinmetall Weapons and Munitions (RWM), and which was unveiled in late August at the RÜ.NET 2023 that took place in Koblenz, Germany. The system could be seen by a much wider audience two weeks later in London, at the DSEI 2023 exhibition.

The starting point for this system is the existing warhead of the SMArt 155 artillery round, SMArt standing for Suchzünder Munition für die Artillerie 155, Ammunition, search-used ammunition for artillery). To develop this munition a joint venture known as GIWS (Gesellschaft für Intelligente WirkSysteme) was formed by Rheinmetall and Diehl Defence. The 155 mm round contains two submunitions; once it reaches the target area the two submunitions are released and descend under a parachute, their sensors start looking for enemy tanks. When one of those is identified the munition is activated and the explosively formed penetrator hits the tank from above.

The SMArt 155 has been used in combat in Ukraine and is therefore combat-proven. However the munition is having obsolescence problems, hence an upgrade programme has been launched by Germany, which will allow re-starting the production of the SMArt 155, the legacy version being in service with Australia, Germany, Greece and Switzerland, and is qualified for use in the United States. While this artillery round drops the submunitions over the target area coming from above, the ADW idea is to exploit the same submunition launching it from the ground up to a height that would allow them to descend for sufficient time to locate the tank.

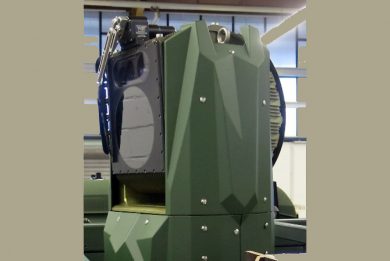

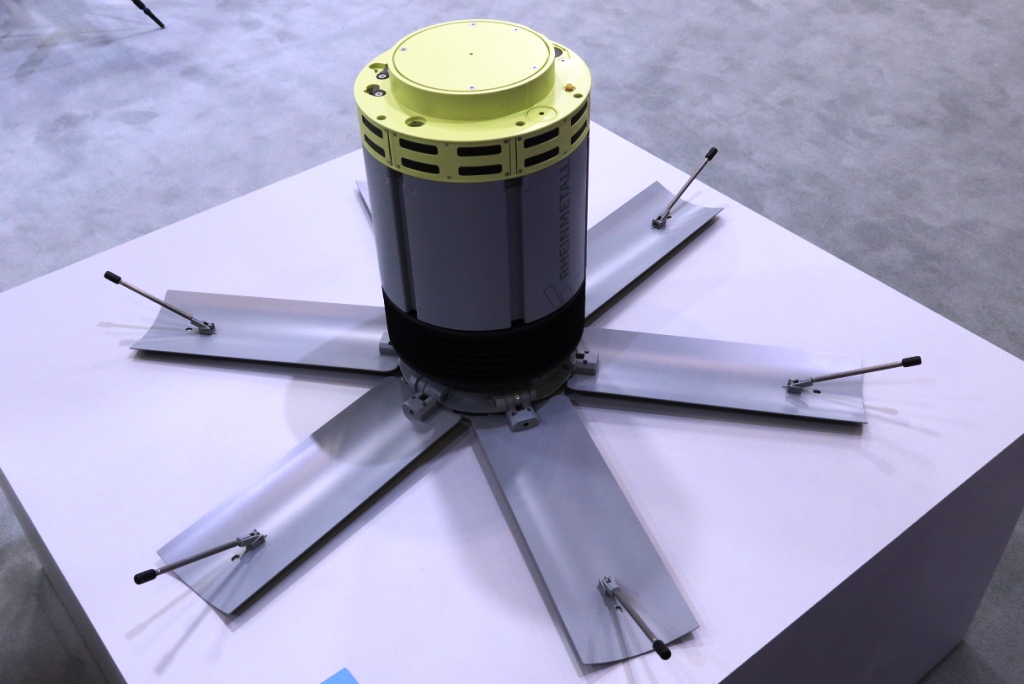

The idea is to create a barrage of smart mines capable to launch those submunitions once they have identified the threat, exploiting current technologies to maximise the effects thanks to networking and coordination eventually led by artificial intelligence. The ADW comes in the form of a cylinder with a 234 mm diameter and a 187 mm height, weighing less than 25 kg. Six radial stabilisers hinged at the bottom of the cylinder, which open up when the mine is placed, each carrying at its end one microphone used to gather sounds from the battlefield. The acoustic sensor is only one of the three used, the other being a seismic one, while the last is a radar sensor, which small antennas are located at the top of the main cylinder.

The sensor suite is being completely renewed compared to that of the late 1990s, exploiting new technologies. While seismic and radar sensors are mostly used to acquire the target, EDR On-Line understood that classification and identification are mostly devoted to the acoustic sensor that exploits a data-base of signatures containing those of both wheeled and tracked vehicles.

Te “brain” of the mine gets all the information coming from the sensors and once identified the threat as an enemy vehicle it elaborates the launching data. Not many details were provided however EDR On-Line understood that ADW mines are not working on their own but are connected among them as well as with a higher level decision-making centre, probably manned but exploiting also AI-supported algorithms. Considering the tactical situation the system will decide which actuator will be used against which target, s well as which target must be hit first in case of multiple targets. This may allow optimising the use of the ADW munitions, but these could also act solely as sensors, the upper level calling in for example loitering munitions to cope with the situation.

When an ADW is tasked a mechanism at the bottom of the mine will tilt it towards the firing direction calculate by the system in order to deploy the submunition over the target area. Compared to the artillery-released submunitions here these reach a lower altitude, around 180 metres above ground, but the search area is more limited, the intervention range being over 100 metres distance from the mine itself. Once in the air the SMArt155 submunition activates its infrared and millimetre wave sensors to aim its explosively formed penetrator towards the intended target. Should the mission be called off before firing, the ADW can be re-programmed as it can be remotely armed, disarmed and rearmed at will.

Fully ITAR-free, the ADW is sufficiently hardened to withstand a launch by artillery rockets, by mine dispenser, by logistic vehicles, and obviously by hand. Once deployed it can remain in the field for over three months. RWM is continuing the ADW development, the aim being aligning it with the SMArt 155 upgrade programme, production of the modernised ammunition being planned for 2027.

Photos courtesy Rheinmetall and P. Valpolini