Saab teams with Divergent Technologies to move towards adaptive design and production

Looking forward to the evolving needs of the defence market, flexibility and short development to in service time being among key elements, Saab teamed up with Divergent Technologies, a California based specialist in next-generation digital manufacturing, to move towards a new concept of design and production

“Defence industry is definitely facing a transformation,” Marcus Wandt, Senior VP, Head of Group Strategy and Technology at Saab stated in his opening remarks at the on-line briefing titled “Creating hardware and software” provided to a selected group of media. The new geopolitical landscape, with war and increasing tensions in Europe, is leading to the need of rapid delivery of large volumes of systems, while in the meantime a lot of new technology is being developed and utilized in defence equipment, consolidation among defence companies as well as partnerships creating a very dynamic environment. “We can see the combination between the traditional industry and startups, finding each other and creating something that is very useful to keep people and society safe, which what we’re about at Saab,” Marcus Wandt added.

Underlining the need to put together legacy technology, experience, and know-how with emerging ones, he highlighted the necessity to leave the hardware-defined world to join the software-defined one. Saab, and more specifically the Gripen BU, made its proof with the development of the Gripen E avionics, designed to be quickly and easily upgraded. Artificial Intelligence (AI) is part of the game, “AI in products for Mission Advantage” being the first pillar of Saab move into the future.

Adapting to requirements that might change rapidly is a must, and this means that hardware must become as “flexible” as software, and this brings to “AI in development for Augmented Design an Engineering”, which is the second pillar. At Saab there is an entity whose task is to “defy the conventional”, an internal startup known as The Rainforest. “Today I am going to share part of this, and this is tied to fuselage manufacturing,” Axel Bååthe, Head of The Rainforest at Saab, told the audience. “In a traditional fuselage, we’re quite defined and limited by tooling. If we want to be more flexible, we need to find a way to manufacture that is more defined by code, and of course, innovations in terms of robotics and additive manufacturing play a key role in this.”

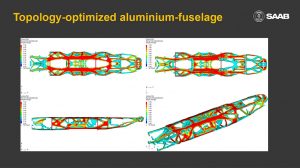

Another degree of freedom is that new approaches allow manufacturing shapes that are limited only by the algorithm. “Geometry is of course a limiting factor in traditional manufacturing, and if we want to do complex shapes, it becomes very difficult and expensive. With a software-defined manufacturing method, we can have essentially unlimited freedom,” Axel Bååthe explained, adding that “We can have biometric, more topology-optimized structures because we can let the design tools optimize for physics, placing structure exactly where the loads are instead of enabling manufacturing.” But design is only a first step. From design come instructions to be loaded on 3D printers, transferring any modification straight into production. Not only, digital factories can be deployed around the world, adding a quick ramp-up capability, spare parts being now stored as codes and not anymore as physical items. All this is becoming reality thanks to the work done by Divergent Technologies, the US partner with which Saab teamed up for this journey into the future.

“What Divergent has created is a truly digital and fundamentally adaptable production system, what we call Divergent Adaptive Production System, DAPS in short,” Cooper Keller, Divergent’s Chief Programs and Operations Officer, told the audience from his office in California. “ It allows the engineers that are most familiar with the vehicle and the requirements to very quickly move from the requirements to a structure that achieves both the requirements of that system, so achieves the stiffness performance, achieves the durability performance, while also being fundamentally manufacturable using an adaptable production system,” all software tools allowing doing the model-based systems engineering, the topology optimization, the manufacturing assessment, all in parallel. And then being able to move immediately into printing and assembly, he explained.

Divergent had clearly in mind that a printer large enough to produce a whole chassis or fuselage did not made sense, therefore it developed a large format laser powder bed machine “that is printing 15 to 30 times faster than anything else that is seen in industry,” Cooper Keller stated. The DAPS software allows engineers to assess how the final piece will be split into individual constituent elements. These are then assembled using a fixtureless assembly cell, no further details being provided about this key feature. EDR On-Line understood that the DAPS is already being used in the aviation and in the automotive world, 40-50 kg structures being produced, the single individual element maximum dimension being 700x700x835 mm. These are then assembled into a larger structure; the only available information on the assembly system is that the joints have been fully qualified for safety critical applications in both automotive and aerospace applications, they have been tested in all conditions in the last eight years, and are fully validated, being considered at TRL 9, but no details can be provided as these are under Non-Disclosure Agreement.

Saab is working on an unmanned air platform that should fly in 2026. Its development, or at least that of its’ fuselage, is done exploiting DAPS capabilities.

“This fuselage is around 5 meters long, 1 meter wide, and 60 centimetres high, and will have a payload capacity of roughly 200 kilograms. Compared to a traditional fuselage, part reduction is over 99%, if we count all type of attachments, fasteners, rivets, etc. This, of course, dramatically lowers the lead time from design and change to assembling it. We have worked together with Divergent to automate the assembly line this as much as possible. Sustainability in a wide context is super important and a strategic mission for us at Saab, and this type of manufacturing, compared to traditional machining, saves a lot of waste material, above 90 percent saving, compared to a more subtractive machining methodology. Another area where we found it very attractive to work with Divergent Technologies, is speed, as the software manufacturing system can be scaled to manufacturing thousand plus of these size of structures per year,” Axel Bååthe underlined.

Adopting the new design methodology Saab engineers defined where they want to have keep-out zones, where they need to install equipment in the fuselage structure, and then let the algorithms work, defining where the structure is required to be and optimizing it for performance and mass. The result is quite different compared to conventionally produced fuselages. “Something that struck me when working with these types of topology optimization algorithms is that nature is pretty clever. It was a surprise that these shapes look this organic and this sort of skeleton-like. On the other hand, I think nature is very good at optimization and creating only the structure required per kilogram of mass that needs to solve the task at hand. And I think this is what we’re seeing here as well,” the Head of The Rainforest added. And nature evolution has to do with the California-based company name. “Our name was derived from the concept of Darwin’s divergent evolutionary biology,” Cooper Keller explained, underlining that instead of millions of years of predatory evolution, here it is minutes of supercomputing and AI iterative evolution.

Cyber security issues have been taken into consideration, as well as qualification issues, regulatory authorities being quite cooperative, EDR On-Line understood now that data are available to demonstrate analytically the design work. DAPS is being considered not only for developing new systems but also in the maintenance, repair, and overhaul business. “We received a drawing on a Saturday and by Tuesday we produced a part that had equivalent stiffness, equivalent fatigue life compared to the baseline part, all that in three days, taking off 45% of the mass,” the Divergent Technologies representative underlined.

Saab promised new insights into this fascinating new world of digital manufacturing in the near future, the DAPS methodology being of course applicable not only to fuselages but to most other parts of an aircraft, aerodynamic optimisation being a possible further outcome. While Divergent is multiplying its facilities in the United States, a first digital factory should be created in Europe in 2028. More to come …

All images courtesy Saab