Thales unveils its TSA 6000 IFF active E-Scan interrogator

By Luca Peruzzi and Paolo Valpolini

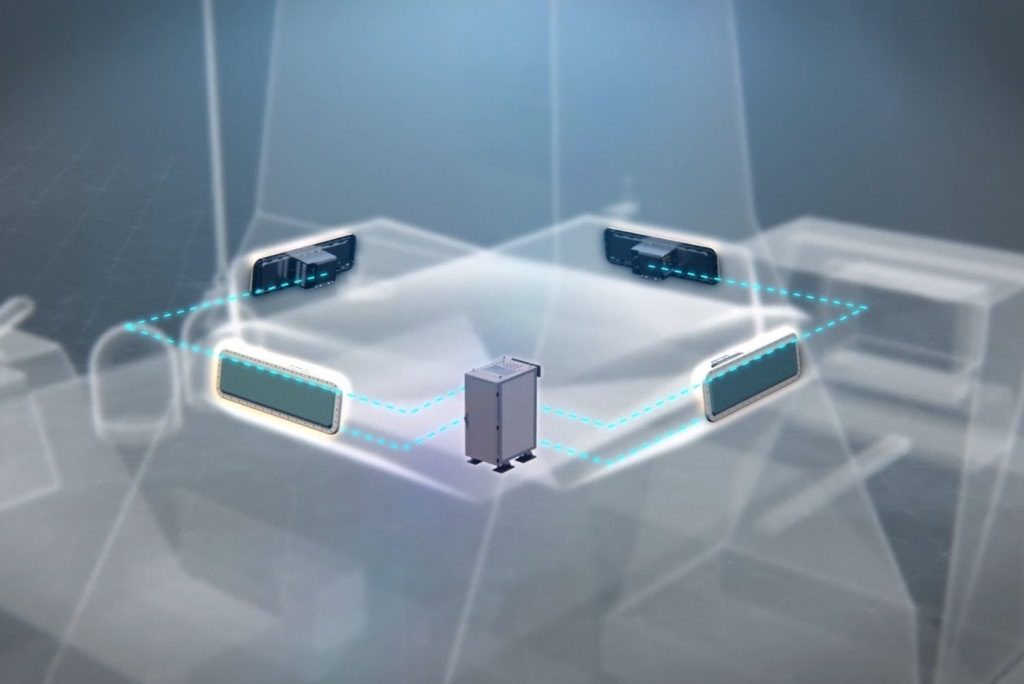

To answer the latest needs in terms of naval air defence identification Thales has unveiled its new TSA 6000 IFF, based on four flat panel AESA antennas operating simultaneously, each providing a coverage of around 100°, that can be easily integrated in any ship structure in order to provide full 360° coverage, the declared range being 360 km .

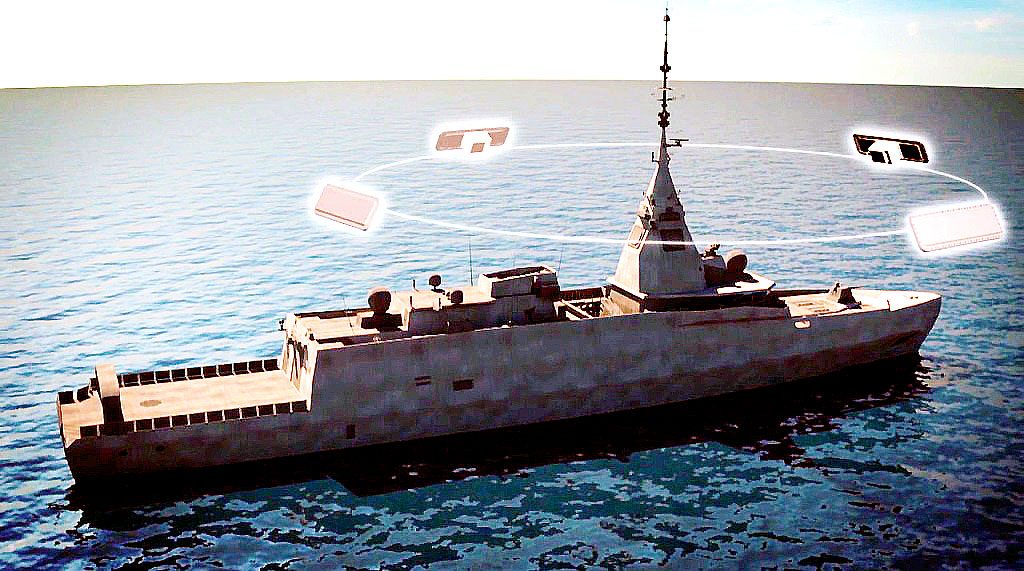

“This new system will allow to take more accurate and faster decisions,” Marie-Pierre Guilbert, Thales IFF Product Line Manager said, underlining that the first application of this new system will be on French Navy FDI (Frégate de Défense et d’Intervention), which is being equipped with Thales 3D SeaFire multi-function radar, the delivery of the first-of-class being forecasted for 2024.

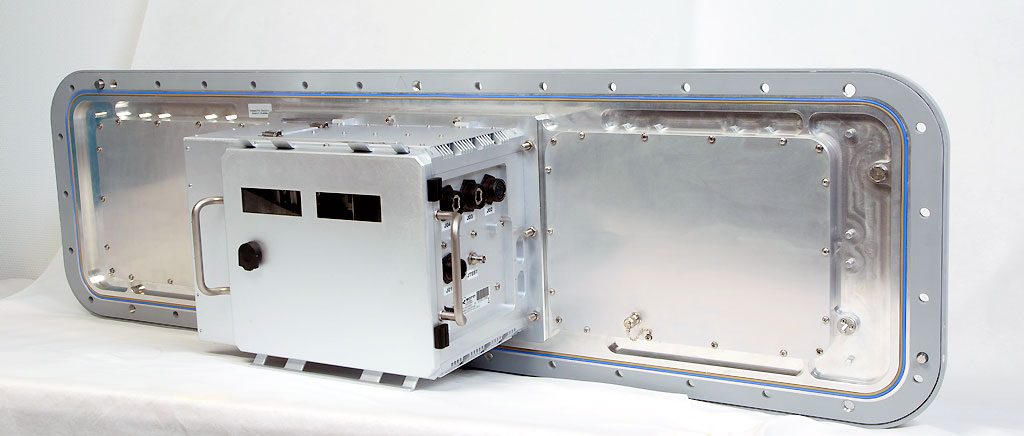

The latest evolution of Thales’ BlueGate IFF family, the TSA 6000 panels are 1,464 mm long, 430 mm high, and have a depth of 314 mm, the flat panel containing an undisclosed number of transmitting-receiving modules, which ensure a graceful degradation capability, and a processing module to coordinate all TRMs, cooling being ensured by natural convection. According to Mrs. Guilbert, “the TSA 6000 can track well over 1,000 targets at a time.”

Each flat panel antenna, which weighs 55 kg, is then digitally linked to a COTS computer fitted into a 19” rack, that manages the coordination between the antennas. The system covers all commercial, A, C and S, and military IFF standards, 1, 2, 3/A, 4 and 5 (Level 1 and 2), and is fully compliant with Mode 5 Stanag 4193 edition 3 (equivalent to US DoD AIMS 03-1000B), this standard having become mandatory for units engaged in NATO operations since July 1st 2020, and Mode S level 2.

“The adoption of AESA flat panel antennas provide considerable advantages in terms of quick response compared to rotating IFFs,” Mrs. Guilbert added, “but also provide improved availability and unmatched reliability.” Giving away all mechanical parts considerably reduces the chances for failures, hence MTBCF is much higher, over 5,000 hours; not only, HUMS (Health and Usage Monitoring Systems) have been inserted, allowing predictive maintenance, thus further increasing availability. All this also allows to reduce cost of ownership. Flat panel antennas, which can be installed in a totally independent way compared to the on board radar, even if the latter is based on AESA flat panel antennas, also contribute to reduce as much as possible the ship radar signature, while their overall weight, around 220 kg, is much lesser than the average available IFF system of that same class, according to Thales.

In early 2021 the company has delivered a first test system with two panel antennas to the French Navy and Naval Group, to be integrated into the FDI onshore test bed at DGA’s Air Defense Systems Experimentation Site (SESDA) in Saint Mandrier. The delivery of a full four-panel system is planned before year-end. This might well be installed on the first-of-class FDI frigate for completing the integration process ashore before starting trials at sea.

Designed hand in hand with the French Navy, the TSA 6000 looks also to the export market, numerous potential customers having been identified and talks being already undergoing, EDR On-Line understood, which of course remain confidential. “The geometry of the system allows it to be easily integrated both on new ships as well as on existing ones,” Marie-Pierre Guilbert says, explaining that not only the TSA 6000 can be installed to replace older IFF systems, but it can also be added i.e. to cover blind sectors. Asked about competitors, the Thales IFF Product Line Manager said that legacy rotating radars belong to a whole different category, while existing AESA solutions are bigger and heavier that the TSA 6000, which therefore has an edge over other IFF systems of its class. Entirely produced in France, the TSA 6000 is not subject to ITAR regulations and does not fall under the German export control rules.

According to Marie-Pierre Guilbert the new Thales IFF system is ready for production; it will be available on the market one year after the delivery of the first system to the Marine Nationale, which means late 2022, and a customer might expect a delivery time of 12-18 months from the order. The TSA 6000 is not limited to naval use and can also operate in conjunction with ground-based multi-function radar systems.

Images courtesy Thales