The Constellation-class frigate programme: schedule assessment ‘ongoing’

The US Navy’s Constellation-class guided-missile frigate programme is experiencing workforce shortages at the shipbuilding site of the first-of-class platform. These are the primary drivers of the delay in the delivery schedule, which was originally slated for late 2026

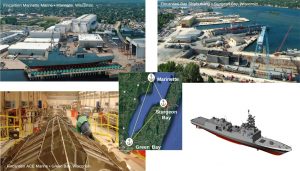

As part of Fincantieri Marine Group, the Marinette Marine shipyard in Wisconsin won a contract in April 2020 for the detailed design and construction (DD&C) of up to 10 guided-missile frigates, of which the first-of-class is under construction while three others are on order.

Speaking and answering media questions about the developments, milestones and challenges being experienced by the programme for the first-of-class guided-missile frigate shipbuilding and delivery during a briefing given during the annual Surface Navy Association (SNA) symposium (9-11 January) in Arlington (VA), the US Naval Sea Systems Command (NAVSEA) PMS 515 Frigate programme deputy manager acknowledged potential schedule delays in the programme due the workforce issues. Asked about the slippages and how they could impact on the delivery schedule, Andy Bosak said the assessment is “ongoing”, without providing further details.

Speaking during the Future Force Panel at SNA 2024, Rear Admiral Kevin Smith, the head of the Programme Executive Office for Unmanned and Small Combatants, from which the frigate PMS 515 depends, unveiled that the first-of-class frigate keel laying will take place this spring. Previously the same milestone was planned to be reached in August 2023, with a slippage of about seven months, if the same event will take place in late March, as EDR On-Line understood, although the programme delays could reach a year.

“Like the rest of the (shipbuilding) industry in the United States”, speaking about the workforce issues, “we do have challenge in the schedule. We are working on that. Fincantieri communicated to us of challenges within the schedule,” Bosak said. FMM is “short of few hundred people across both the blue- and white-collar workforce,” he added responding to media questions, “with issues extending across multiple trades and disciplines.”

“We are doing our analysis as the Navy does deep dives on causes and effects and various different levers of which we can pull within the shipyard. We need to, as a programme office, work with our leadership and find out what we want to do and from that we will make the assessment as to what the actual schedule impact is of where we are,” the deputy programme manager explained.

“We are supporting the US Navy’s decision to perform their own analysis on the challenges and impacts to schedule that we highlighted. After their analysis, they will make the announcement about any delay in delivery of the first-in-class ship,” Eric Dent, Fincantieri Marine Group director of communication, told EDR On-Line.

The US Navy Secretary Carlos Del Toro announced later the same day, he has directed the acquisition community to conduct a comprehensive analysis of the Navy Shipbuilding portfolio “to provide an assessment and actions for achieving a healthier US shipbuilding industrial base that provides combat capabilities that our war fighters need, on a schedule that is relevant.” This study is due in 45 days.

“I remain concerned with the lingering effects of post-pandemics conditions on our shipbuilders and their suppliers that continue to affect out shipbuilding programmes, particularly our Columbia-class ballistic missile submarines and Constellation-class frigate,” Del Toro said in the same statement.

Overcoming workforce shortages

Having said FMM shipyard is short of few hundred people across both the blue- and white-collar workforce, the programme deputy manager highlighted the activities the US Navy and the shipyard are carrying out to overcome the shortage.

The Surface Combatant Industrial Base (SCIB) $50 million funding provided in FY 2023 to FMM have been used for prioritizing workforce retention and development projects. “Essentially, they get a (first part of the) bonus if they’ve been working there for this next year and then a second part of that bonus when the first ship is launched,” explained Bosak (for a total of $15 million) with these bonuses showing early positive results. A $3 million human resources data analytics project was awarded in November while additional projects are under development and review for the remaining $30 million, leveraging on aggressive recruit and build upon apprenticeship and training programmes. Both the Navy and FMM are working with local councils to support them in applying for and win Federal and State grants for things like housing improvements in order to attract additional workers.

The programme office and FMM are also looking to push early production scope at the other Fincantieri shipbuilding facilities, Green Bay and Sturgeon Bay, creating a federated shipbuilding plan as Fincantieri is doing with its shipyards in Italy and abroad for both military and cruise vessels. They are also looking to shift work at these two facilities to reduce the burden on Marinette Marine for the other two shipbuilding programme: the Littoral Combat Ship (LCS) for the US Navy and the Multi-Mission Surface Combatant (MMSC) for the Royal Saudi Navy. These programmes are still employing personnel which was expected to pass to the frigate one.

“As we move forward in the long term, we will look at things like automated manufacturing and streamlining the digital environment within the shipyard,” Bosak highlighted. As we will explain later, welder robotics are already installed on the new shipyard Panel Line facility (Building 30). Fincantieri has developed together with Comau company, which is active in automotive industry, the new generation MR4Weld robot which is being procured to start large-scale use in Italy and the shipbuilder wants to use it also in the US to accelerate productivity and increase quality. These enhancements are expected to support the Fincantieri’s aim to increase the production rate from three frigates every two years to two ships every year.

Shipyard renaissance and revolution

Fincantieri invested more than $300 million into Marinette Marine industrial base, revolutionising the facilities and production process. Due to low temperatures at which the FMM workers are operating in the winter season, most of the activities are to be completed in climate-controlled facilities. This, together with the need to improve the shipyard facilities to cope with the most modern technologies and processes, pushed Fincantieri to add critical enhancements. Today, the shipyard sees a large new facility (Building 35), which accommodates giant steel plates of raw steel to begin the journey to become a warship, which is connected to the new Panel Line site (Building 30), where steel is prepared, marked, cut, and welded on an automated assembly line with state-of-the art robotics welders. Other facility enhancements include a renewed Blast and Paint facility (Building 20) that allows to speed up activities and increase efficiency, satisfying the latest health and safety standards, as well as a newly available Hull Erection facility (Building 34) and a shiplift. Building 34 has two bays each allowing for ship modules assembly with superstructures for one Constellation-class platform, plus additional modules for one third ship length. Currently one bay is occupied by the initial modules for the Constellation first-of-class frigate while the other accommodates the second MMSC for the Royal Saudi Navy under hull assembly. This together with the new shiplift represents a huge development for the shipyard production rate and among the national shipbuilding industrial base. The new ship lift built by Pearlson Shiplift Corporation is capable of handling vessels of nearly 10,000 tonnes and allows for the launch and retrieve of vessels that can be outfitted to near completion and tested inside facilities before being launched into the adjacent Menominee River. Until recently the slide launch system used by the shipyard requested to complete the ship outfitting after the launch, as certain components could be damaged in the dramatic splash. According to the presentation provided by the deputy programme manager, the shiplift construction is completed, with shipyard testing underway and Navy test and certification scheduled for early this year.

Programme past and future achievements

Looking to the main achievements reached in the busy programme for 2023, Bosak pointed out to the transitioning from class functional engineering to detailed design, which adds 3D modelling to show the configuration of equipment and spaces on the ship. The latter is planned to be completed in fiscal year 2024 with the on-going inputs flow coming from the fleet end users. FMM has started construction on the first-of-class FFG 62 Constellation frigate, and the factory acceptance trials were conducted on the various equipment including diesel generators, electric power motors and air conditioning units. The US Navy has certified the Frigate Build Specification and completed ship scale model testing at Naval Surface Warfare Center Carderock Division Maneuvering and Seakeeping Basin. However, Bosak hasn’t provided details on the encountered challenges on responding to US Navy specification.

The programme office established combat system requirements and initiated equipment procurement. Exploiting the key programme risk mitigation elements, the NAVSEA representative recounted the Program of Record (PoR) Combat System and its elements leveraging on proven technology, sustainment, and training programmes. The programme office established testing sites for the combat system at Morristown and Wallops and initial cyber testing has already been conducted on the first US Navy platform with cyber resilience requirements. A Land Based Engineering Site (LBES) was established for the propulsion system testing at Naval Surface Warfare Center Philadelphia Division with a facility overhaul commencement ceremony took place in August 2023. The FFG 62 LBES capabilities will consist of vessel-representative equipment, the ability to simulate or emulate propulsion configurations of the ship and replicate operational parameters. It will allow crews to train on a live plant prior to their own ship’s commissioning. Additionally, the site will be able to support future modifications or updates to ship systems and equipment throughout its life. Overhaul activities are on-going on the facility structure, and design of the vessel-representative equipment layout is expected to get a contract with the procurement and installation activities to be launched toward the end of 2024.

On the future operational side, “one of the biggest changes to the programme that does not affect the ship at all is the switching from a dual crew concept to a single crew concept,” the NAVSEA representative unveiled. The initial plan was for a single crew concept applied to the first six ships and then make the transition to a “Blu/Gold (crew) concept”. Now the single crew concept is applied to all the ships and the programme office is working to satisfy this requirement in term of ship operations, training, and support.

Looking forward to the Constellation-class frigates homeporting, the first six vessels will be based at Naval Station Everett (WA) (FFG 62 to FFG 67) on the Pacific Coast, while the follow-on will be homeported at Naval Station Mayport (FFG 68 to FFG 71) on the Atlantic Coast. The next batch of 10 frigates will see the first six assigned to Naval Station Everett while the remaining (FFG 78 to FFG 81) at Naval Station Mayport. The programme office has been working with these naval stations, mostly the Pacific facilities, looking at port loading, considering updates to the peering and maintenance and support.

Photo courtesy Fincantieri Marinette Marine, NAVSEA, Rolls-Royce