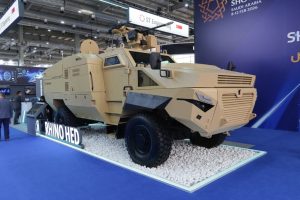

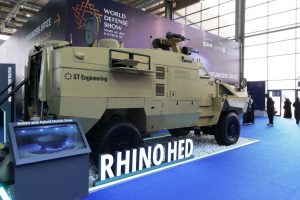

WDS 2026 – ST Engineering unveils Rhino, its hybrid and connected 4×4 next generation protected vehicle

At the World Defense Show in Riyadh ST Engineering of Singapore introduced to the public the first product born out of the company work on hybrid propulsion. Named Rhino, it exploits the company Central Drive Hybrid Electric Drive Kit, which itself has become a product

In the past years ST Engineering exhibited in various events its development programmes in the hybrid propulsion domain. WDS 2026 marked the debut of a true product, a 20,000 kg gross vehicle mass 4×4 armoured vehicle which has already found a launch customer, who remains unknown, the vehicle already being in low rate initial production since late 2025.

The Rhino, as the vehicle has been named, is based on ST Engineering Central Drive Hybrid Electric Drive Kit, which is also proposed for the upgrade of existing vehicles in the 15-20 tonnes category. EDR On-Line understood that also the kit itself has found a launch customer, also unknown, the company being active in the upgrade of an unspecified fleet of vehicles. In both cases the resulting vehicles will feature the typical advantages of hybrid propulsion, increased export power, silent drive, extended silent watch, extended range, and improved mobility.

The hybrid drive adopted sees a diesel engine reloading two sets of 400 V batteries located along the rear compartment sides. Through a set of high voltage distribution units these power two 225 kW electric motors; each one of those is linked to a shaft, connected to one of the axles, a two-speed gearbox ensuring optimal mobility on road and cross-country terrains.

The Rhino is based on structural monocoque hull that ensures increased crew survivability especially against mines and IEDs blast. It adopts two solid axles with parabolic leaf springs that ensure good off-road mobility, further increased by the typical near instant high torque provided by electric motors. The vehicle is 7.3 metres long, 2.7 metres wide and 2.8 metres high, without turret, and it carries a 4,500 kg payload.

The new ST Engineering 4×4 vehicle offers Level 2 protection both ballistic and antimine, under wheel and under belly, although the high payload allows flexibility for configuring protection according to customers’ needs. At full load the Rhino can reach a maximum speed of 100 km/h, and at cruise speed it has a 780 km operational range. Should the crew need a silent approach, it can travel on batteries only for 25 km at 50 km/h, switching off the 360 hp diesel engine acting as extender. In this condition it can carry on silent watch for a whole day. The Rhino can also export up to 150 kW of powers, replacing mobile generators and acting as mobile charging station for unmanned electrically-powered systems. As for mobility, the Rhino can overcome a 60% gradient, travel on a 30% side slope, overcome a 0.4 metres high vertical obstacle, and ford a 0.9 metres deep water obstacle. Its turning circle is 18 metres.

But the Rhino is more than a simple hybrid vehicle, ST Engineering having added to the vehicle most of its recent developments. It adopts a fully digitised architecture and is fitted with a digital dashboard, full 360° situational awareness system providing all round view in the 3-5 metres area, digital side mirrors, and rear object detection system.

In the personnel carrier configuration it hosts a two-man crew and ten dismounts, seated on two rows of inside-looking energy absorbing seats, infantry entering and leaving the troops compartment via a rear powered ramp. ST Engineering proposes the Rhino also for other roles such as signal, ambulance, mortar carrier, maintenance, as well as for C-UAS and MUM-T roles, the latter being the one on display at WDS.

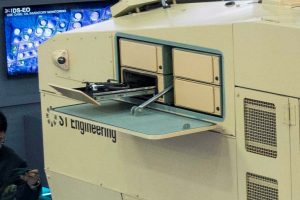

The vehicle exhibited was fitted with an integrated UAV launch system; on the right of the vehicle a side hatch was opened in the rear compartment letting out a tray containing a VTOL mini-UAV. Four such trays were available in the module, ensuring not only precise landing but also immediately starting recharging the UAV batteries as soon as this landed. EDR On-Line understood that this is only one of available configurations; apart from this horizontal solution, a vertical solution has also been developed, in both of them the crew being unable to reach the UAVs from inside. A third option, dubbed vertical/reloadable, was also studied, allowing for example the use of expendable UAVs, spare being hosted in the vehicle. All those solutions are UAV-agnostic, dimensions obviously dictating the possible choice.

The Rhino is also ready to operate with UGVs. ST Engineering puts forward an in-house option under the form of its Taurus 4×4 platform, but here too the vehicle is as much as possible UGV agnostic. In the case of Taurus, this would be towed by the Rhino, a quick-releasable tow bar allowing to let it start its autonomous mission without the need for the crew to expose itself to possible threats. This configuration, known as MUM-T, for manned-unmanned teaming, fully exploits the recharging capacity ensured by the hybrid configuration of the vehicle. In this configuration operators are seated on the left side while on the right we find a megascreen allowing to monitor the situation and unmanned systems behaviour.

The Rhino exhibited at WDS was also optimised for the C-UAS mission, being equipped with an Adder Twin remotely controlled weapon station. Also produced by ST Engineering, it can be armed with two different weapons, in the case of C-UAS missions the choice being for automatic grenade launcher, using ST Engineering 40 mm airburst grenades, or for a low recoil 30×113 mm gun, as the one seen at WDS.

The prototype seen in Riyadh probably does not represent the configuration/s adopted by the launch customer, as it is in fact a showcase of all ST Engineering capabilities. No details were provided on the versions being adopted by the customer, EDR On-Line understanding that the switch from LRIP to mass production should happen in late 2026, early 2027.

Not many details were provided on the upgrade kit contract currently underway. ST Engineering representatives underlined how the Central Drive solution is the best one for such operations, as it does not require changing suspensions and axles, avoiding going back to the OEM. The company is also developing solutions that will exploit in-hub motors, but these are considered not mature enough for heavy vehicles, they are being used on UGVs. Two major issues must also be overcome, that of amphibious capability and that of the increased thermal signature. On the other side advantages are quite obvious, as in-hub motors will allow to avoid the use of mechanical links, axles and shafts, giving the designer a much higher freedom when developing the vehicle. But to see this we will have to wait some more years.

Photos courtesy ST Engineering and P. Valpolini