XTRAIM, the new Thales day-night rifle sight for XXI century soldiers

By Paolo Valpolini

Listening to soldiers coming back from theatres of operations, and talking about individual equipment, they make it clear that one of the systems they would never give up is the thermal sight. Once something reserved only to Special Forces and other elite units, and quite cumbersome and heavy, nowadays, from high level of “optical science skills”, the advent of effective uncooled thermal sensors with reduced dimensions and power consumption has opened an era of sights that have similar size and weight of top notch optical sights, giving an edge to the warfighter not only when fighting both at night and day but also when he or she needs to decamouflage a potential enemies’ hidden i.e. behind a bush to engage them on time.

Usually thermal sights for small arms came as a dedicated system or as a clip-on that worked in-line with the day direct view optics sight; these meant that a soldier had to carry two to three systems, the weight thus being doubled. Recently a new type of sight started to surface, made of a direct view red dot sight, allowing reflex targeting keeping both eyes open for maximum situational awareness, coupled to a thermal sensor.

Thales followed this path giving birth to the XTRAIM. “In the last few years we launched a complete modernisation programme of our optronics systems, the main focus being mass reduction and the jump into the perception beyond the vision,” Pascal Sécretin, Thales Imagers and Sensors product line director, tells EDR On-Line, “something which is a key issue when considering dynamic combat.” The XTRAIM is the latest of the systems developed by Thales at its centre of excellence for dismounted soldier optronics in Saint-Héand, in the Centre of France. “First of all we managed to cut the mass to one fourth of what is needed today to have similar performances,” Pascal Sécretin explains, “all this allowing the soldier to fight with both eyes open for close combat phases, hence a much better situational awareness, with recognition ranges similar to the effective ranges of assault rifles and light machine guns.” To this end he adds that the soldier can easily switch from one reticule to another, depending on the weapon-ammunition coupling he uses, “some tens of reticles being saved in the sight memory. “We can even develop new reticles tables based on special requirements, but this is mostly for highly specialised operators,” he says.

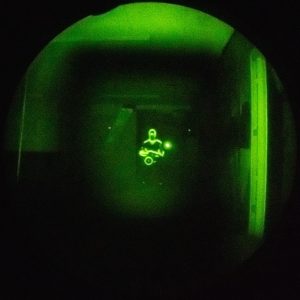

Another issue was coupling thermal imaging (TI) from the weapon sight and image intensification (I2) displayed thanks to the NVG. Until now it was impossible to look through IR clip-on sight with NVGs due to their architecture. “We developed a patented optical architecture that allows the eye to focus to infinity with the NVG and through the XTRAIM weapon sight, allowing thus the soldier to get the benefit from the I2–IR fusion. As an example, Thales NVGs present 40°, 47° or 51° I² observation FoV while looking through the XTRAIM the soldier gets a 14° IR decamouflage FoV at night”, Mr. Sécretin tells us, the I² giving the all-round situational awareness while the XTRAIM permits decamouflaging opponents hidden in the night and behind some masks such as bush, smokes etc.

The new sight day optical channel has a 14° FoV and a 1.6 MOA “red” dot, giving a x1 magnification, the red dot being generated on a high luminance OLED (Organic Light-Emitting Diode) screen, the window sight size being 30×24 mm. An undisclosed number of pre-set illumination levels are available for the red dot, both for day operations and for night ops, the latter being NVG compatible. The company brochure indicates that the thermal channel is based on a 640×480 matrix thermal sensor with 12µm pitch developed by Lynred French company. Looking at the latter company products, this is the latest generation of ATTO digital microbolometer family IR detectors, which according to Lynred is the smallest VGA sensor on the market, with a size of only 16.5×16.5 mm, something that definitely helped Thales in reducing the lens diameter, hence the weight. The sensor also has a low consumption, less than 300 mW, which ensures long operating time; in thermal mode the XTRAIM can operate for over 7 hours in standard conditions, while when using only the “red” dot the endurance increases to over 500 hours, the system being powered by two CR123 batteries. The thermal channel has the same FoV of the day one, and can be used in two different modes, Outlining or Full IR fusion processing. In daytime the XTRAIM can be used as a standard red dot sight, in fused mode injecting the thermal image into the sight exploiting the OLED screen, or in full thermal mode; in the latter case the sight features a x2 electronic zoom allowing to get a closer image of the target. At night the soldier usually wears night vision goggles; he can then use the sight in the normal red dot mode, brightness levels being as said NVG-compatible, or he can combine the NVG view with the thermal one using the fused day/night mode of the XTRAIM as anticipated. Finally he can obviously use the XTRAIM in thermal-only mode. According to Thales the thermal reconnaissance range is over 510 meters while the identification range is over 270 meters on a human target.

The thermal channel is hosted in the lower part of the sight, a 170 mm long parallelepiped body that carries on the sides the press-buttons allowing to operate the sight; the day sight is located at the rear top, eye relief being 90 mm. “We developed the XTRAIM exploiting first of all the simulations tools in our Innov’Lab, which allowed us to present to operators from different countries our solutions, and get their feedbacks that led us to a 1.0 Human Machine Interface, We used that solution on our first demonstrators, that were built using as much as possible 3D printing, although elements that had to sustain high levels of strain had to be produced by machining. These demonstrators were provided to potential users that brought back further comments,” Pascal Sécretin tells us. Each demonstrator was used to fire some thousands ammunition, overall the XTRAIM has been used to shoot more than 40,000 rounds, As an example of the results of that iterative process Mr. Sécretin says that the initial product had a three-button interface, but during trials it became evident that soldiers tend to put the carrying hand much further than what was initially considered, hence the third button was an encumbrance, so the production system will have only two buttons. “Another issue was compatibility with as many weapons as possible. One issue was that with belt-fed machine guns, that normally have a cover that must be opened to fit the new belt. In the initial design the XTRAIM was longer than the actual one, the 170 mm length being the result of that compatibility study.” The sight can be fitted to weapons that feature a NATO Accessory Rail, which is backwards compatible with the STANAG 2324/MIL-STD 1913 rail.

The XTRAIM weighs less than 530 grams batteries included, and can be fitted with a x3 optical magnification add-on when used against targets at distance, which increases the D/I ranges respectively up to 607 and 320 meters on a human target.

As said the XTRAIM sight was designed at Thales’s centre of excellence for dismounted soldier optronics in Saint-Héand, and is entirely assembled at this site. All its components are in majority designed and produced in France, some in Europe, hence it is inherently ITAR free.

The configuration is now fully frozen, and mass production is planned to start in 2022, a number of armies having shown their interest for this new day/night compact sight since it was discretely exhibited at SOFINS last June.

“However this is only the beginning,” Pascal Sécretin concludes, “as we have a development roadmap that will bring the system to become part of the collaborative combat scenario carried out by the next generation of soldier systems. We thought thoroughly on how to integrate our equipments in order to accelerate the detection, identification and neutralisation of a threat, and we are already working on new solutions. What is certain is that this evolution will not change the form factor and the mass of the XTRAIM.”

Photos courtesy Thales