Arquus Technodays: looking at the future

By Paolo Valpolini

Organised by Arquus at Port-Marly, 10 km west of Paris, Technodays 2021 gathered industry, military and media to see the technologies the company is considering to further improve its products, the only vehicle present in real being the prototype of the Scarabee, the 4×4 reconnaissance vehicle which was launched at IDEX last February.

“We aim at finding the best solutions to improve performances, mobility, protection and ergonomy, in order to increase the effectiveness of our systems,” Emmanuel Levacher, the company CEO, underlined introducing Day Two of this year Technodays. “To do this we profit of the lessons learned from our customers, the French Army first, as well as of our partnership with many other companies, as we cannot do all by ourselves, and last but not least we exploit synergies within the Volvo Group, to which we belong,” he stated. A civil truck was visible at the entrance of the exhibition hall, fitted with hybrid propulsion, while the only all-electric loader available on the market was also on display. “We are always considering solutions in the civil domain to adapt them to the military world, but this is not always possible,” Mr. Levacher said, also underlining the importance of increased autonomy, in robotised systems, as well as digitalisation.

An example of synergies between the civil and military domain is the proposed diesel-electric hybrid powerpack for the Griffon, exhibited at the Technodays, which exploits the 150 kW electric machine employed on the aforementioned commercial truck. This is coupled to the 400 hp diesel engine and will provide extra power, increasing acceleration as electric motors provide immediately the maximum torque, while allowing silent motion when electric-only propulsion will be used, not to mention the considerable on-board electric power available for extended silent watch operations.

In July 2020 the French Minister of the Armed Forces, Mrs. Florence Parly, announced the availability of a hybrid Griffon demonstrator by 2022. After thorough trials, this should become a prototype by 2025, with first operational hybrid Griffons to be delivered in 2028-30, if the roadmap will be respected.

As anticipated, the only real product exhibited at Port-Marly was the Scarabee. The vehicle has now matured to a point that, should a contract be filed to Arquus, the company would be able to deliver the first vehicle within two years. Currently only a single prototype has been produced, which is constantly updated.

Talking to the programme manager EDR On-Line learned that when stealth movement is required, the driver can select two modes; “A” (Approche, approach), switches the vehicle in standard all-electric mode, while “F” (Finale, final) reduces noise to a minimum, i.e. slowing down cooling fans. The standard propulsion mode is the hybrid one and the management system has been upgraded. Power storage is provided by a series of Lithium-Ion batteries specifically developed by a French company working in the automotive competition field. The armoured floor providing protection against mines and IEDs is made of three layers; the upper one is that on which seats are installed, a second floor providing stand-off, the third being the one directly exposed to the potential danger. Batteries, which are pretty slim, are located in the gap between the second and the third floor, in a sealed compartment. According to the company, when the Scarabee carries out stealth surveillance, batteries allow for over half a day of silent watch with the remotely controlled weapon station, three CONTACT radios, the SIC-S command and control system, and the air conditioning, all turned on. In one of our last talks on the Scarabee subject we were told that the French Army asked for conventional rather than sliding doors; in fact widening the audience the poll result was a 50/50 score between the two configurations, depending on the type of unit and the use. In example police special units prefer sliding doors, in order to be able to move with open doors and not to have the door stuck when operating in constrained spaces, like narrow roads. On the other hand conventional forces seem preferring the classic hinged door. EDR On-Line understood that having developed both solutions, the hinged door being from the moment only on computers, Arquus will maintain the two options in its portfolio, letting the customer to choose his preferred solution.

At Technodays 2019 Arquus exhibited a concept model of a trailer. That concept has very much evolved, the company having considered which missions might be the most apt to be carried out by what is now named Mission Extender. This work was mostly done in 2020, and now the technical concept is being launched. A dedicated team is working on that project, made of Arquus personnel and of one element coming from an undisclosed robotic company as the new system will be something between a trailer and a robot. Its development will involve some partners, and the platform configuration has still to be optimised, i.e. the number of axles has yet to be determined.

The Mission Extender will be fitted with a generic teleoperation system, which will be spirally improved adding autonomy elements, to reduce the operator’s workload, the final aim being to have a fully autonomous system under human supervision. Easily interchangeable mission modules will then be developed, according to missions identified. A key requirement is that the Mission Extender must not change the Scarabee behaviour, thus it has to be wholly transparent to the driver, who should not even notice it is towing it, or them, as a concept movie showed more than one Mission Extender towed by the same Scarabee. The programme will follow an incremental path, with go/no-go steps to be overcome both in terms of technical and business considerations. Arquus intends to time its development with French Army robotisation programmes, in order to be ready slightly in advance to answer land force requirements.

Another programme is even more in its infancy; at the digitisation stand a movie proposing a series of uses of virtual windows to be adopted on armoured vehicles was visible. Arquus intent was to stimulate comments from the visitors of Technodays 2021 in order to understand how to develop virtual windows allowing the crew to improve situational awareness, with augmented reality helping stepping up from awareness to understanding. Arquus will then develop a proof of concept acting as integrator, as it will of course work in team with companies specialised in cameras and screens. Once a demonstrator will be available, this will allow getting real feedback from potential customers. For the time being Arquus is concentrating only on windows and not on the windscreen; according to the company, the latter requires a latency of less than 80 milliseconds, while windows can accept a latency more than double, which makes things much easier in terms of image processing.

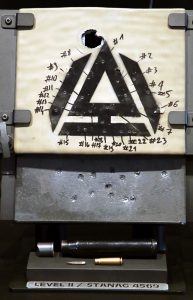

As an armoured vehicles manufacturer, the Arquus R&D department gives a high priority to protection solutions. Activities consider both ballistic and blast, work being focused on the process, materials and assembly. Different examples could be seen on the dedicated booth. Material hybridation allowed developing armour packages with a 50% surface density compared to typical 500 brinell armoured steel. An example of a Level 2 add-on package was exhibited together with the vehicle basic armour; 23 armour piercing rounds in 7.62×39 mm calibre were fired from 30 meters distance on an equilateral triangle with 15 cm sides; most of them went through, the add-on armour slowing down and destabilising the bullets that indented but did not perforate the vehicle armour, the same being true for a bigger shrapnel simulating an artillery impact. A Level 1 solution was also exhibited, while a Level 3 package is also available. All those solutions are mature and available to Arquus customers. No areal density and thickness data were provided.

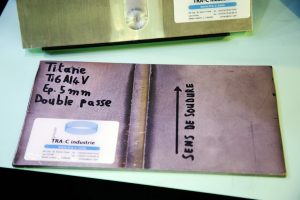

To carry out complex shape elements assembling welding has always been the standard solution. Arquus is moving to friction stir welding, which allows avoiding fusing materials, and on this it is cooperating with French specialist TRA-C industrie Group.

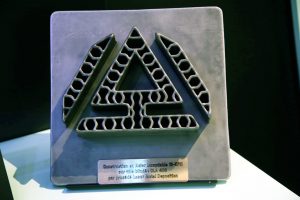

Additive manufacturing is another domain that is being developed at Arquus. Direct metal deposition allows providing a much greater freedom in terms of geometries and dimensions, adding material only where needed, and increasing productivity. According to R&D Arquus responsibles, the company has mastered this technology with stainless steels such as 17-4 PH, 15-5 PH and .420S, as well as with high-entropy alloys providing characteristics 50% higher than conventional steel.

This R&D programme is carried out in the framework of the Optifab project launched by the French Délégation Générale pour l’Armement in cooperation with the Agence de l’Innovation de Défense, which aims at developing technologies capable to improve blast-resistant floors. Arquus is the industrial partner, the project being now in Phase 2. The team already carried out some tests, first results showing a minimum gain between 20 and 30%. The aim is to carry out real demonstrations in one-year time, the technology being currently considered at TRL 5, or low TRL 6.

Exploiting additive manufacturing, the development team produced the door of a VAB armoured vehicle, lowering its weight by 20-25%. According to Arquus the result showed some defects, but since the company has mastered the material involved. A key element is cost, the development team stating that also this has been mastered, cost being coherent with the gain in weight and performances.

The 2021 edition of Arquus Technodays was not limited to the company itself, numerous partners being also present. Among those we can mention CerbAir, Internest, Precision IO, Squadrone and Robotic Industry.

Specialised in C-UAS solutions, Cerbair has been in discussion for quite some time with Arquus, and 4-5 months ago the project for a vehicle-based modular solution saw a considerable acceleration. The two companies are currently defining the various types of mission. The aim is to propose a ready solution within 2022.

From C-UAS to UAS, Squadrone exhibited its Stork quadcopter together with Internest; the latter developed a Local Landing System capable to automatically recover the UAS on a platform even in GPS-denied scenarios and adverse weather. Feedbacks from the around 50 systems currently provided to potential customers for demonstration led to give up the 2.4 GHz frequency as this was subject to too many interferences, to increase the range and strength of the system, Internest planning to have a fully industrialised version of its system in fall 2021. A further evolution that will include a battery reloading capability should be ready for 2022, either for the third French Battlelab demo or for Eurosatory. The two companies cooperate with Arquus to provide the OEM with a viable solution for increasing its vehicles ISR capacity, allowing operators to remain under armour while launching and recovering the UAS.

Another company involved in unmanned systems was Robotics Industry, with its Brain reconfigurable UAS/UGV. This is based on a central module hosting the computer, sensors, and batteries, to which either wheels or arms equipped with rotors, as well as modular payloads, are fitted. The system automatically understands which type of unmanned system has been created, switching to the right control software, the same happening for the HMI and payloads. Brain UAVs/UGVs are designed to operate in team, according to the collaborative combat model. The solution proposed by Robotics Industry allows optimising not only the logistic footprint, but also costs, as the module containing sensors, the control computer with its software and algorithms, is definitely the most expensive part of the system. Robotics Industry works closely with the military, mostly with Special Forces but not only, in order to generate products as close as possible to their needs. Thanks to this experience is cooperating with Arquus on innovative programmes.

Last but not least, Prevision IO is cooperating with Arquus on predictive maintenance. The company developed a platform based on Artificial Intelligence that was fed with data coming from 20 VAB armoured vehicles purposely fitted with a number of sensors. Elaborating those data the system allowed to anticipate faults, giving a warning some five days before those happened, allowing to anticipate repairs, hence increasing fleet availability. A demonstrator for the Griffon is planned, following the same path.

Photos courtesy Arquus and P. Valpolini