Improved firepower, not only a matter of calibre

“The firepower is the right to exist of an MBT, and in our view the main gun will remain the dominant effector for a tank,” Dr. Tobias Schmidt, Rheinmetall‘s Future Gun System (FGS) programme director states, opening his remarks on the Panther/KF51 lethality.

Main targets for an MBT are obviously enemy heavy armour and other combat vehicles, as well as anti-tank guided missile teams and dismounted infantry. A tank can however be also called to destroy infrastructures, while defending itself from threats coming from the third dimension, namely combat helicopters and nowadays loitering munitions and UAVs.

The big caliber gun will mainly be used against enemy armour, with different types of ammunition such as kinetic energy (KE) and multi-purpose high-explosive (MPHE), the latter also used against helicopter and infrastructures, while secondary weapons are mainly used against infantry targets at closer range, or against drones. “An tank MHPE can generate more fragments than a burst of 35 mm AHEAD rounds,” Dr. Schmidt adds.

More on the 130 mm main gun

The Panther is fitted with the 130 mm main gun developed by Rheinmetall from 2015 on. EDR On-Line already dealt with this subject in past articles but some new information was revealed in Berlin. “To defeat enemy main battle tanks, which is the principal task of the main gun, a greater range is needed as well as a high hit accuracy, we are talking of distanced greater than 3,500 meters, and we also need high effectiveness in order to neutralise the target for the rest of the battle,” Dr. Schmidt underlines. According to figures provided, high effectiveness means the ability to defeat a rolled homogeneous armour equivalent in excess of 1,000 mm thickness, protection being of course nowadays provided by a combination of passive, reactive and active armour. Dr. Schmidt advocates the supremacy of the tank gun in MBT duels as he considers that the protection gap against dive and top attack effectors, such as antitank missiles and loitering munitions, will be closed pretty soon by new forms of active protection systems, leaving kinetic energy still the best way to neutralise an MBT opponent.

Justifying the increase of calibre from 120 to 130 mm, he pointed out the results of a study carried out in the mid 2010s by Rheinmetall, showing that the combination of the L55A1 gun with the DM73 APFSDS round ensured sufficient kill capability against modern enemy targets at 1,000 meters range, the new DM83 adding further 500 meters, this round being expected to become operational in 2024. This was however considered the end of the growth potential of the 120 mm smoothbore gun developed in the 1970s, which means it would not be possible to extend the range and increase effectiveness against new and more protected targets, hence the decision to increase the calibre to answer new requirements defined by customers.

A much higher degree of automation is also required; on one hand the number of systems installed in the turret is constantly increasing, therefore automated functions allow reducing the crew workload. These will also become key in the future, as Rheinmetall foresees the advent of big calibre unmanned turrets, which might also be installed on unmanned platforms.

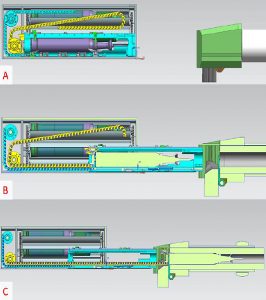

Beside adding automation functions, the automatic loader is a must due to rounds weight as well as to the above considerations. The Rheinmetall design team aimed at increasing the 1.5 km maximum range of the lower calibre gun by 1,000 or even 2,000 meters, all this in a gun system capable to be fitted in a platform with a maximum combat weight of 40-50 tonnes, as the company aims braking the weight increase spiral that brought current MBTs close to the 80 tonnes mark. Being a new system, the 130 mm was designed with an inherent growth potential, to cope with increasing protections on the enemy side. “We aim at reaching TRL6 in 2026. In the first four years, since 2015, we did a lot of optimisation to find out the right cartridge for this future gun system, and in parallel we did conceptual work on the autoloader and investigations in weapon components,” Dr. Schmidt explained. Before coming to the current gun, Rheinmetall considered numerous calibres and chamber volumes, between 120 and 157 mm and between 10 and 20 litres, and extreme service condition pressure between 700 and 800 MPa. Maximum barrel length was set at 8 meters. Interfaces between weapon, ammunition, target, turret and loader were considered. Interior ballistics had to be optimised for a much bigger chamber than that of the 120 mm gun. Three different types of prototype ammunition were developed and test fired since 2016, while a number of other parameters were analysed, including recoil forces, muzzle energy, barrel and weapon mass, and other. The next four years were devoted to develop subsystems, such as different barrel variants, the recoil system, the cradle and the autoloader, bringing them into the turret, and then starting testing at subsystem and system level. “We have carried out the first firing testing of the weapon in the turret, although not fully integrated, and then we did additional accuracy and performance testing, hitting an A4-size target at 1,000 meters distance with four shots,” Dr. Schmidt unveils.

The autoloader was one of the key components; developed by Rheinmetall Air Defence in Oerlikon, near Zurich, it has now been integrated into the turret allowing to prove the whole loadings sequence. Requirements call for a less than 3 seconds loading time and less than 2 seconds feeding time, the breech requiring around 1 second to move backward and one more second to go forward. Loading is controlled by a series of sensors, and as the system is brand new the movies shown during the presentation allowed for some extra time, 3-4 seconds, for safety checks. “As muzzle energy is of around 18 MJ we want to be sure everything is right before shooting,” Dr. Schmidt underlined.

He also confirmed the already available data of 20 shots, separated in two magazines, on both sides of the loading mechanism, adding however that the number of rounds might be increased up to 30 “but losing a lot of space around.” As a quick reload procedure is available, this ensures that 20 rounds are enough, according to the speaker. The autoloader can not only ensure the loading of the ammunition but the unloading as well, a peculiarity compared to other systems that are unable to do the unloading. “This is because we look at using it into an unmanned turret, so it must be able to do all operations,” he added, explaining that time needed for unloading is around 6 seconds, as pulling the round needs to be done with lower forces compared to ramming. This means that unloading a round and shooting the next one will take around 9 seconds. Moreover, the Panther/KF51 autoloader is also able to reorganise ammunition in the magazines, which might allow for example filling up one of the magazines, empting the other one in order to replace it. As for precision, “What was surprising was that with the gun integrated into the turret we achieved a higher precision compared to what we obtained in bench firing adjusting the gun every time,” Dr. Schmidt unveiled. We must consider that a KE round weighs around 32 kg while an HE round is at around 40 kg, while the travel between the position in the autoloader to the rammed position in the chamber is around 2.6 meters.

Secondary armament is key to defeat secondary targets

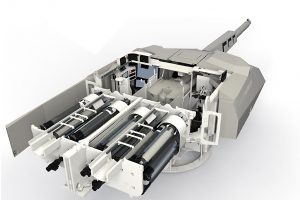

As said, Rheinmetall is proposing its Panther with a 20 ready-rounds load therefore secondary armament is key to defeat secondary targets. The reduced number of rounds available to the 130 mm gun compared to MBTs armed with 120 mm guns, a Leopard 2 carries 42 rounds, led to the choice of a 12.7 mm heavy machine gun as coaxial weapon, capable to defeat light armoured and soft targets at medium ranges. “This is fitted with some automated functions as, for example, there is nobody to solve a misfire should this happen,” Dr. Schmidt pointed out.

The machine gun is controlled by a generic interface which makes it weapon agnostic, and is fed from a 1,250 ready-round box. Beside this, which covers the frontal arc of the turret, Natter RCWS is located at the rear; this can be also armed with a 12.7 mm MG, but can also accept a lighter weapon, such as a 7.62 mm MG, or a 40 mm automatic grenade launcher, and provides full hemispheric coverage its elevation ranging from -15° to +85°. With a weight of around 100 kg, it is fitted with its own sighting system, and can be used by every crew member. Armed with the 7.62 mm MG, the Natter proved its effectiveness against slow flying UAVs at ranges up to 300 meters exploiting the automatic tracking and the grid-firing mode that ensures sufficient dispersion to hit the target, 2,500 ready-rounds being available. A high-end drone detection and recognition system needs to be installed, to ensure a proper C-UAS capability.

Considering the 40 mm AGL option, high velocity 40 mm airburst grenades are also pretty effective against UAVs up to 600-800 meters, especially if hard-kill effectors are coupled to soft-kill systems, such as EW effectors, which jam the drones reducing their agility, something much needed considering the relative low velocity of 40 mm grenades, V0 being around 240 m/s. To do so the programming end of the 40 mm ammo must not be affected by the jamming, therefore grenades are fitted with a special programming system. Rheinmetall estimates that a drone can be engaged with a 6-8 round burst, an ammo box allowing 3-4 engagements.

Although not yet integrated, the Panther can be fitted with a high-energy laser weapon station, the beam being fed through the commander’s optronic sight. According to Dr. Schmidt energy storage can be installed at the rear of the tank, thanks to the engine and the gear set have reduced dimensions compared to those of the original Leopard 2. Data provided mention an output power between 4 and 10 kW, with an engagement time of 4-5 seconds, 4-5 engagements being a realistic option before needing to reload the energy source. The main task for such an add-on system would of course be countering incoming drones and LMs.

As already highlighted in previous articles, coming to long-range effects, one of the magazines of the autoloader can be replaced by a loitering munitions canister, containing for example four UVision Hero 120 40 km range LMs fitted with antitank or multi-purpose warheads. Handling LMs might definitely be the task of the fourth crew member.

The system status

Coming to the status of the lethality package, since 2016 Rheinmetall carried out more than 300 shots with its 130 mm gun in its various development stages, reaching a V0 between 1.700 and 1,900 m/s, which means approximately an 18 MJ muzzle energy, a 50% increase over that of the 120 mm gun system. “As growth potential, we have new technologies that we did not implement yet. The current round is pretty close to a DM63 or DM73. This being a reliable technology that we used for proofing the weapon, but we are planning introducing at a later stage new ammunition technology to further improve performances,” Dr. Schmidt stated.

EDR On-Line was also told that following the Eurosatory unveiling in June 2022 the Panther/KF51 went through numerous testing. Among those the full loading cycle was tested on the move in increasingly difficult conditions, such as on a 60% slope or a 30° side slope, while firing on the move has not yet been done. However static firings were done, testing all the chain up to operational firing. This phase will end in March 2023, when a further testing phase will start, which will include all electronics.

Photos courtesy Rheinmetall and P. Valpolini