Inside the FDI: a detailed description of its innovations

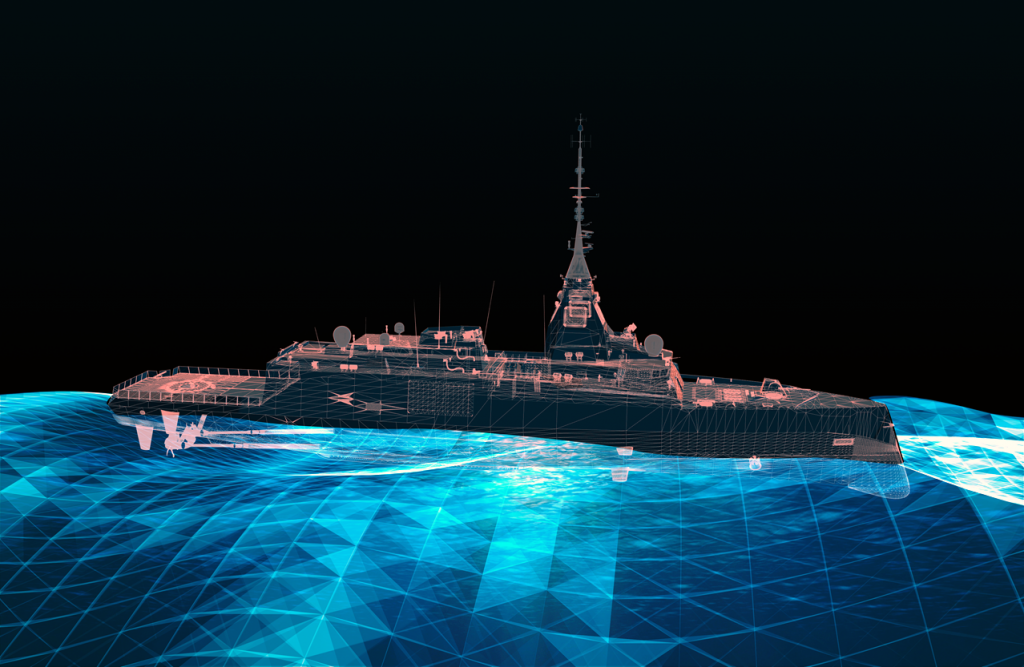

The FDI as well as its export Belh@arra variant has been conceived since its inception as a digital native platform, which will benefit from an unparalleled level of digitalisation thanks to a new information technology (IT) architecture centred on two data centres, allowing for a very large capacity for data storage and analysis.

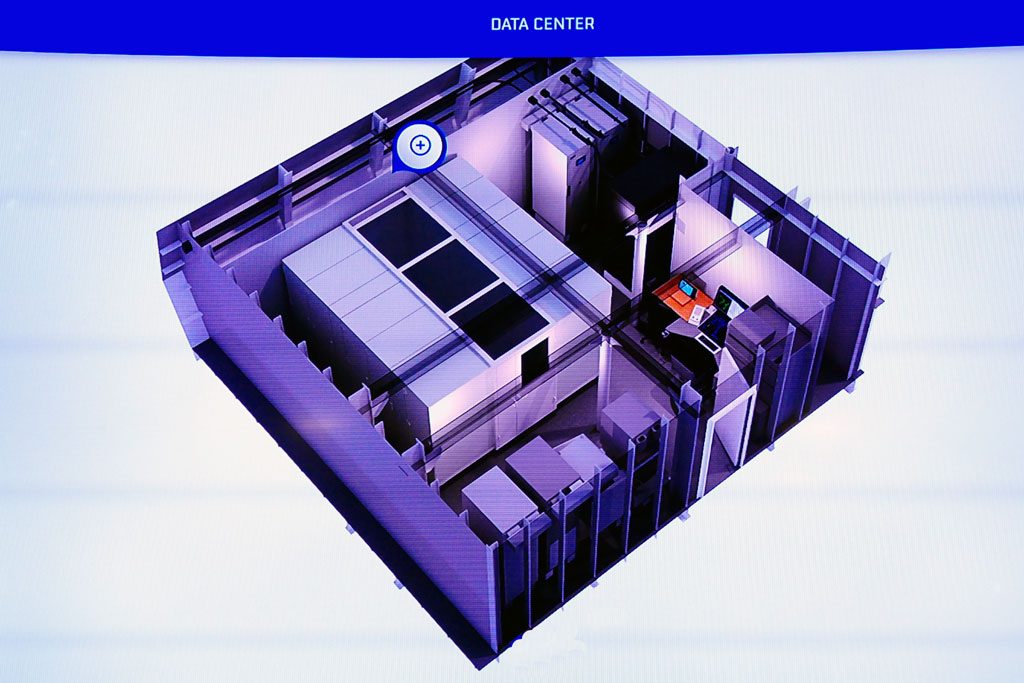

The most innovative feature of the FDI is the main core of the new-generation digital architecture applied for the first time to a French Navy’s platform and represented by the clustering of shared computing resources in two dedicated ‘data centres’. “The ‘digital backbone’ of the ship, these two data centres host almost all the computing power, the combat management system, the platform management system, the communication and the integrated bridge/navigation systems being all ‘virtualised’ and considered as applications hosted in those centres,”, Boy explained.

The Naval Group representative compared this architecture to ‘the one on the iPhone’. The resilient fully-redundant ‘two data centres’ and network configuration has been selected to increase platform survivability. “One of the two data centres is located into the Panoramic Sensors and Intelligence Module (PSIM) together with the sensors suite and the Combat Operation Centre (COC) while the second is physically separated and accommodated into the platform back aft, the connection between them offering full suite redundancy”, he continued. All the computing power is available for all the applications at the same time, in order to optimise available resources. Moreover, having the ‘brain’ of the ship concentrated in two rooms, allows to physically and electronically protect them from external threats, in particular cyber ones. “As anticipated, the systems are virtualised: equipment, computers and servers are separated from the software. This reduces footprint and optimises power consumption allowing easy hardware renewal/upgrade and software technology update as well as easier access control and armouring to protect the ship digital backbone”, he said. According to the few available details, standard tools as well as standard industrial blade processing units for the hardware are used for virtualisation. Each data centre contains 10 cabinets to give an idea of the computing power.

Another main advantage of this architecture is the easy collection of usage and diagnostic information, which introduces the so-called e-maintenance concept, to be discussed later on.

New generation warships are embedding more and more computer and software-based components, not only in combat systems, but also in platform systems and equipment such as navigation and integrated platform managing systems (IPMS) also called ship management systems (SMS). This may introduce vulnerability towards cyber-attacks, all the ‘digital ship’ in itself and the environment and communications together with the maintenance and supply chain contributing and exposing the platform to these threats. The FDI’s Cybersecurity Management System (CyMS) supervisory software-based console developed by Naval Group has particularly intuitive human-machine interfaces (HMI). This user-friendly system offers to the operator a centralized real-time view of information on the cyber state of the platform, by gathering information from equipment, and analysing in detail with regard to the ship’s operating modes, enabling the detection of cyber attacks against the vessel.

The software provides feedback to the operator, and once the corrective decision has been taken the system makes it possible to automate and monitor the commanded actions. “The CyMS is a unique, operations-oriented interface for real-time (cyber) security monitoring, capable to manage all dedicated capabilities, from attack detection to reaction, providing update and control, intrusion detection, qualification and remediation scenarios. In case of incident, an alarm is raised showing all impacted systems, with associated level of seriousness. The system gives the operator a list of possible remediation actions provided with details, and the crew can react according to operational priorities”, said Hervé, explaining how the system operates and reacts on the operator console, according to given mission priorities.

The FDI design also introduced for the first time on a French Navy’s platform other innovations from an operational perspective, in addition to human machine interface enhancements. The Command Management System (CMS) provided by Naval Group is based on the experience gained with the SETIS suite of current generation platforms to introduce the latest technology developments and facilitate the renewal and upgrading, to cope with the expected life cycle of the new FDI indicated in up to 40 years. In addition to software and hardware developments with remotely computing and lighter and smaller footprint consoles, the major evident evolution resides in the information exploitation thanks to new touchscreen displays and evolved human machine interface. According to information provided by Naval Group representatives, even if the design is still to be fully defined, the CMS is expected to accommodate 15 multifunction consoles to manage all the sensors and weapon systems. Although Naval Group has released few details, based on the video images of the FDI design development, the new Multi-Function Console (MFC) is centred on a wide vertically-positioned main tactical multifunction screen and a smaller inclined touch-screen display on the console board to interact with the system, together with two lateral smaller displays on the left side of the main tactical multifunction screen. Overall, the CMS requires around 20 million lines of code while IPMS around 7 million.

The FDI programme contract award also sees theThales Group providing a number of latest-generation systems including the new S-band solid-state Sea Fire 500 four-fixed faces (4 FF) AESA (active electronically scanned antennas) multifunction radar, also equipping for the first time a French Navy’s ship. Developed with the support of the French DGA, the software-controlled 3D multifunction radar liquid-cooled antenna provides a full 360° coverage in azimuth and 90° in elevation, which can be scaled according to the platform type and mission requirements. Designed to perform various tasks including volume search, low altitude surveillance, air/surface target tracking, environment mapping, fire control, full uplink support for Aster missiles and kill assessment, the Sea Fire radar family offers common modular architecture with fully digital and software-controlled processing and incremental capabilities. The latter differs for the number of digital transmit-receive modules (TRM) in each of the four antenna arrays, offering redundancy, graceful degradation and easy access. Thales has introduced the radar latest technologies, with full-digital solid-state TRMs applying GaN technology, arranged in 12 assemblies each hosting eight boards with eight TRMs channels, for a total of 64 channels per assembly for each radar antenna, in the case of the Sea Fire 500 radar. With respectively 300+ km and 80+ km ranges in air and surface coverage, the Sea Fire can manage over 1000 tracks simultaneously. The first series-production radar antenna was installed and emitted for the first time in September 2019 on the Saint Mandrier (near Toulon) SESDA (Site d’Experimentation de Systems de Defense Aérienne) facility, for test and evaluation activities in a two faces configuration, while the first full operational (four arrays) radar system will be delivered in late 2020 to naval Group to equip the first-of-class FDI frigate.

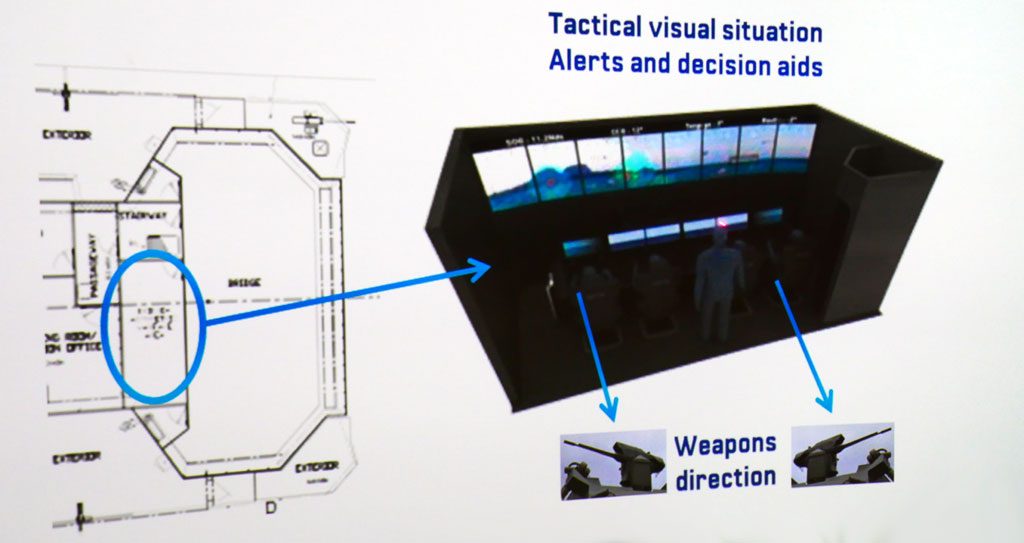

In addition to the new generation SETIS CMS positioned inside the PSIM, the FDI introduced for the first time on a French Navy’s platform the so-called asymmetric warfare centre, or Poste de Commandement de Lutte Contre les Menace Asymétriques (PCLCMA). Developed to deal with non-conventional threats in the close vicinity of the ship, as well as supporting the ship manoeuvring operations, the new centre is positioned behind the main bridge and provides on-watch team with a real-time, all-round day/night ‘virtual scene’ which provides visual information and fuses them with the tactical picture provided by other sensor and networks. The centre is equipped with a 360° augmented reality and integrated high-resolution display on one wall and five work stations plus a director position, which provide tactical visual situation, alerts and decision aids, allowing a small team to optimise the use of all sensors and effectors, including both lethal and non-lethal weapon systems. The centre receives visual data from the CNIM Group’s Bertin Technologies- 4K day/low light panoramic cameras suite and the two sponson-mounted Safran Paseo XLR electro-optical directors positioned on the main mast and providing a 360 degrees coverage. Two of the five stations are devoted to the control of the two Nexter Narwhal 20 mm remote weapon stations, while the centre also manages the two turrets fitted with non-lethal systems provided by Exavision, which include acoustic and optical effectors.

Moreover, located just after the so-called asymmetric warfare centre, the PSIM accommodates a staff room designed for about ten people, allowing the FDI to embark a small group or mission command staff for national and international missions.

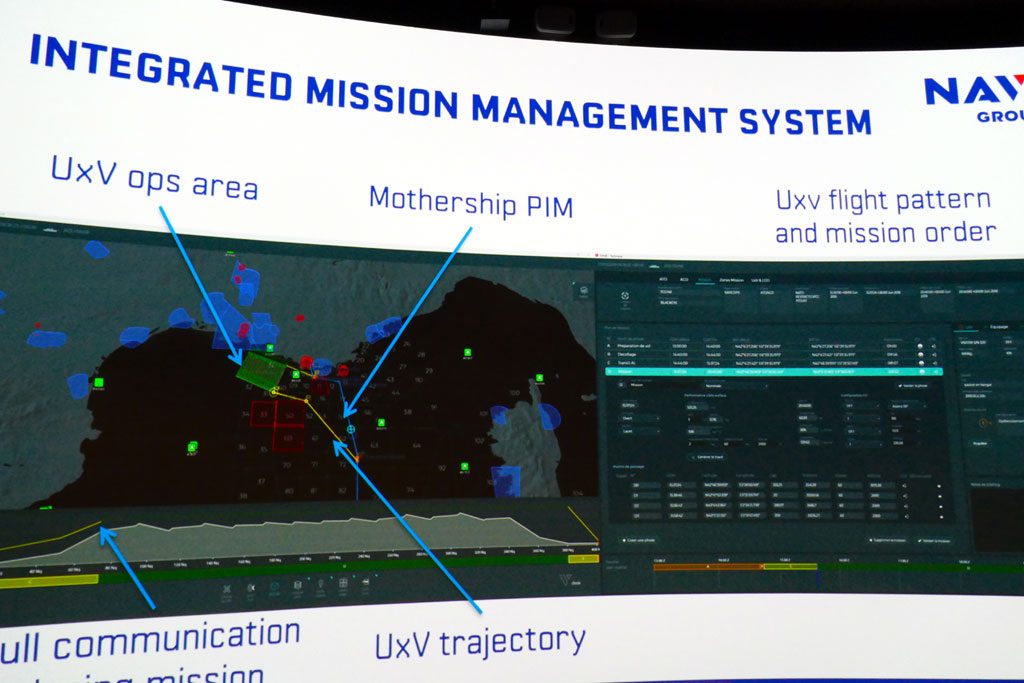

Another peculiarity of the FDI design is the integration since its conception of unmanned systems. Based on lessons learned with vertical take-off small unmanned air system integration on board the l’Adroit OPV and other R&D and development programmes, as well as the French Navy’s requirements, the FDI can embark, and the hangar can accommodate, a VTUAV in addition to one 11 tonnes ASuW/ASW helicopter. Naval Group has developed a software-based command and control system integrated and managed by the CMS which, together with the UAV control and exchange data systems, will be part of the FDI’s equipment suite. The 700 kg VTUAV is under development by Airbus Helicopters and Naval Group together with Hélicoptères Guimbal and other main subcontractors such as Safran, Thales and ONERA, within the DGA’s SDAM (Système de Drone Aérien Marine) demonstration programme for the French Navy, based on the VSR700 platform.

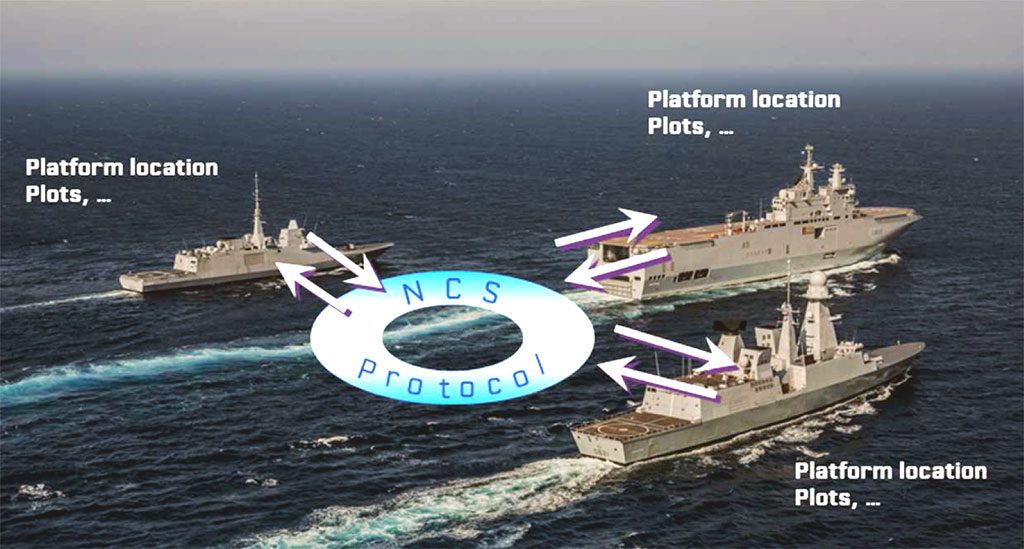

The FDI will also be the first French Navy’s platform to embark since its delivery the Naval Cooperative Surveillance, the so-called Veille Coopérative Navale (VCN) capability. The latter offers cooperative continuity and unicity of threat tracks, the key element for threat evaluation and engagement, explained the Naval Group representative. The VCN is based on the exchange of sensors raw data by using a high data rate network based on internet protocol. The sensors raw data are fused in real time on each unit to create a virtual radar at fleet level, with a common tactical picture processed on the different naval units. The VCN relies on the RIFAN 2 (Réseau IP de la Force AeroNavale or naval and naval aviation’s IP network) digital UHF radio network, currently at the stage of incremental development and validation, which is compatible with the latency of satellite link. In addition to provide the French Navy with a potent information superiority tool, the VCN increases track accuracy by combining detection as well as sensors’ complementarity, which provides benefits against low radar cross-section threats as well as in difficult operational scenarios, such as radar jamming, sensors unavailability, restricted emissions situation and blind sectors.

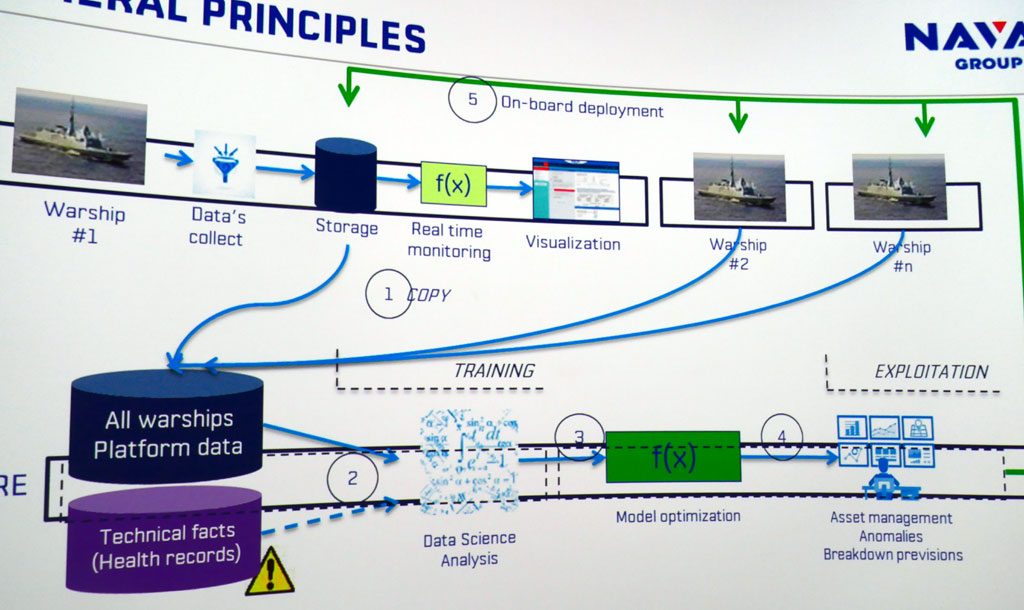

Naval Group, DGA and the French Navy are also working on e-maintenance for the FDI. “Every system is logging information about its status and performance. Analysing this information will allow us and the French Navy to be much more efficient in maintenance, enabling the detection of faults as well as predicting failures”, said Hervé. The conditional maintenance diagnoses the status of the equipment during operations by identifying hints of deterioration or imminent failures, through software and hardware detectors. Data are collected exploiting the ship digital backbone and stored onboard and then transferred ashore into the two data collection centres created by the French Navy, where thorough analysis is carried out allowing to determine the level of maintenance required. The system not only allows to take immediate action, but also works on statistics, permitting to forecast maintenance requirements and life-cycle costs, not only of the same class of vessels but also for other ship using the same components. Naval Group and the French Navy are already working side-by-side in the two ashore centres, located respectively in Toulon and Brest, to incrementally improve the predictive maintenance concept.

Pictorials courtesy Naval Group