Leonardo details its 30 mm X-Gun and announces first two customers

During a press presentation at the company Brescia facility, Leonardo announced that it is about ready to take orders for its 30 mm X-Gun, unveiled last year at Seafuture. It also provided a number of technical details on this new weapon

“Today everybody is speaking about counter-UAS and systems capable to defeat, and today we are on the market with something that we consider to be exactly at the right time at the right moment, with a technology that is totally of our property so that we own the full intellectual property rights,” Luca Perazzo, Deputy Managing Director of Leonardo Defence Business, part of the Electronic Division, says opening the briefing on the new X-Gun in the meeting room at the Brescia company facility, which started operating in 1924 under the name Breda Meccanica Bresciana, the site celebrating this year its 100th anniversary.

Numerous features were already unveiled last year at the La Spezia exhibition, however much more was said during the official presentation of the new product, or should we say new products as two other new guns were announced.

“Current scenarios are leading to constantly changing requirements, and only players that are capable to innovate their products and provide new solutions can keep up with those needs,” Daniele Barbieri, Head of Sales Management Export Small Calibre states adding that “our new 30 mm can answer those requirements, and not only present ones but also future ones.”

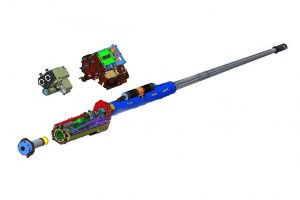

Before getting into technical details, Mattia Forcina, the Head of Defence Mechanical Engineering, who is leading team in charge of developing the new weapons, explained the very first stages of the X-Gun programme, starting from the first prototype of the drum cam, which constitutes the heart of the new gun, and which, when seen from the side, shows a cross that gives the “X” to the gun name. “The principle is quite simple,” Forcina says, “but it is completely unconventional compared to the other players.” The drum cam rotates ensuring all gun operations; in three turns, which is 1080°, one operation is carried out every 270°, respectively feeding the round, ramming it, giving it some dwell time for the firing, and extracting it, which brings some people to call the X-Gun also a cam-gun. According to Leonardo the drum cam system choice allows considerably reducing maintenance compared to other solutions. The X-Gun is fitted with a 30° rotating bolt with six lugs.

The strategic decision to develop a domestic 30 mm gun was taken in 2017, and in 2018 the company funded the proof of concept, which saw the development of the single component that were then put together, allowing a first burst firing at 200 rounds per minute in 2019. The following year the configuration was frozen, leading in 2021 to Prototype 01, which featured a linkless double feeder, a system the company is more familiar with. One year later the same prototype was fitted with a linked double feeder, and the gun control unit (GCU) was finalised.

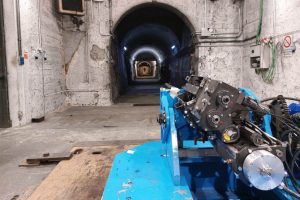

2023 saw the production of three guns, SN002 being the one that EDR On-Line could see firing in the company shooting range, with a single shot in sniper mode, five-round, and ten-round bursts. Leonardo is currently busy with environmental and STANAG 4516 qualifications, before moving to platform integration on naval and land turrets in 2025.

As said the X-Gun will be available with two types of feed; “The idea was to maintain the same receiver, swapping from the linkless to the linked feeder without any kind of modification. This is key under the logistic point of view, as it allows maintaining over 80% spares in common between the two versions,” the chief designer said. Asked about market preferences between the two solutions, Leonardo representatives stated that the situation is still unclear, and this might well be what brought the company to develop a flexible solution capable to be provided in both configurations.

Mattia Forcina underlines that along the development a series of improvements were adopted in order to reduce weight, improve maintainability as well as the form factor, to allow better installation on cradles both for naval and land applications. The X-Gun is 3,555 mm long, while breech block is 431 mm wide and 465 mm high. The barrel, which is produced in Leonardo’s La Spezia facility, is 90 calibres long, hence 2,700 mm; it is fluted, with eight grooves improving cooling and reducing weight while maintaining rigidity, and EDR On-Line understood it has a 8,000 rounds life, V0 and internal wear being the discriminators that bring to replace it when needed. Barrels for naval and land application will all have the same finishing, which is the highest protection level applied for barrels operating in demanding sea environment. It is to note that Leonardo is currently investing 20 million Euro per year to improve its barrel production capacity in all calibres, ranging from 20 to 155 mm, not only replacing existing machinery but also installing new production lines, all this to cope with the increased demand. Most of this goes into what the company defines “small calibres” which means 20 to 40 mm.

The gun seen in action was in the final configuration, the brushless electrical motor being now inside the drum cam, which according to Leonardo allows to save space and to have a better balancing of the weapon. The feeder is now smaller, all various improvements allowing to save around 25 kg, the frozen configuration having an overall mass of 173 kg, respectively 78 kg for the receiver, 60 kg for the barrel, and 35 kg for the feeder, to which we must add 16 kg of the GCU. The latter contains a set of capacitors that allow saving the latest data should power fail.

The rate of fire is over 200 rounds per minute, programmed burst and continuous burst modes being available; a peculiar feature is that the X-Gun is always on safe, the safe being removed only when the fire action starts, although a manual override system allows manual firing in case of power failure. Brass is ejected frontally while links are ejected laterally. Recoil force is comparable to that of competitors, the X-Gun being fitted with a single spring/hydraulic damper and with a muzzle brake that features two series of six cuts pushing vent gases backwards.

Two important features are the sniper mode and the next round selection. “With a light pressure of the trigger the operator allows the round to be chambered and to stop the cycle. It then takes precise aiming at the target, and when it is engaged then with a final pull of the trigger the firing pin is set free and he can fire with no delay. Not only, as ramming and loading generate some vibration, this would affect accuracy. So better accuracy and extremely low latency are the benefits of the sniper mode,” Mattia Forcina explains.

The next round selection allows to shift from one feeder to the other, changing type of ammo, without the need to fire some round in the process, which in the end means a greater number of rounds to be used for engagements. “We can do this because we have a neutral position on our feeder selector,” Forcina explains.

The X-Gun can of course fire all 30×173 mm ammunition, however for the C-UAS role the MF-ABM (Multi Fragmentation-Air Burst Munition) under development by KNDS Ammo Italy (formerly Nexter Arrowtech) will be the ammo of choice. It is fitted with a smart fuse which programming is ensured by a fuse antenna setter is installed inside the gun; the time of flight before detonation is provided by the fire control system (FCS); it is based not only on target distance and ballistic tables, taking in count the average muzzle velocity for that type of round, but also on the type of incoming threat. This allows to detonate the ABM round in front of the incoming target at the right distance, the FCS being also capable to decide the number of rounds needed to cause maximum damage at the right and the timing between each round, adapting the firing rate to obtain the optimal fragments pattern in front of the threat, EDR On-Line understood. This is conducted firstly identifying the threat; EDR On-Line understood that once integrated in the turret, the X-Gun will exploit a UAS data base “with hundred thousand images and videos” constantly increasing according to Leonardo representatives. AI-based algorithms are definitely part of the process, and although no more details were provided it is quite obvious that self-learning modes will improve efficiency along time, all AI related issues being developed in cooperation with other entities of Leonardo.

To further refine the time-of-flight data, two passive magnetic coils are inserted into the muzzle brake, to allow the fuse to “read” the true V0, which is used for fine-tuning the delay data for utmost accuracy. As the “brain” is in the ammunition, this makes it nearly impossible to jam it.

Beside the ABM mode the MF-ABM under development by KNDS Ammo Italy (formerly Nexter Arrowtech), can also be used in point detonation (PD) mode, being activated at impact on target. Talking to company representatives EDR On-Line understood that the round has already been tested, however system testing should be carried out before year end. The steel spheres diameter contained in the front of the warhead, which generate a cone with a reduced angle, no data being available, was done on considerations of kinetic energy versus density, fragments generated by the steel body at detonation adding extra killing power on a wider angle. According to information, the company decided to keep the programming system as an add-on kit, should some customer decide to go for a different type of programmable ammo.

The X-Gun is electrically powered, the supply being provided by a 24 VDC source, with a peak absorption of 390 A. Leonardo considers the X-Gun at TRL6, however it should step up one notch very quickly, and the company considers it is ready to take orders. In fact, two contracts have already been signed, delivery time for the first systems being 24 months from contract signature, while once production will be launched production time will be reduced to 12-18 months.

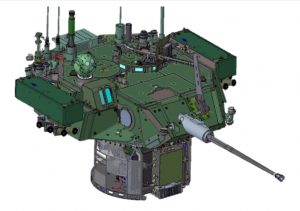

Coming to applications, let us start from naval ones, for a very simple reason: here two customers have already materialised, one being the Italian Navy. The Marina Militare decided some time ago to move from the 25 mm to the 30 mm, and it will be the first customer for the Lionfish 30, the new member of the Leonardo Lionfish naval turrets armed with the X-Gun to be installed on PPX OPVs. With a mass of around 1,600 kg without ammunition, the non-penetrating turret hosts the electronics and servos on the right side while ammunition, up to 200 rounds, are hosted on the left. Fully stabilised, the turret training range is ± 155° while elevation is -20°/+70°, with training speed and acceleration respectively 140°/s and 220 °/s2, data for elevation being 90°/s and 220°/s2. The optronic suite includes a day camera, with detection/recognition/identification ranges of 9.5/4.8/3 km, while the thermal camera provides DRI of 12/6/3.5 km, a laser rangefinder with a 10 km range being also fitted. The second contract for the Lionfish 30 comes from Canada, the Royal Canadian Navy having selected the Leonardo turret for its Canadian Surface Combatant project. The prototype turret should be available in 2025, EDR On-Line understood.

Leonardo is developing two turrets for land applications, one unmanned and one manned, which will join the HITFIST family, with which they share many commonalities. The former will have a mass of around 1,400 kg without ammunition, a total of 150 rounds being available, with a basic protection around Level 2. Reloading will be conducted under armour, and the turret will have Hunter-Hunter, Hunter-Killer and Killer-Killer operating modes. A 7.62 mm machine gun mounted over the main gun will provide short range suppressive fire, antitank missiles being considered as part of the turret growth potential. The adoption of a slip ring allows continuous 360° training while the elevation arc is -10°/+60°, no speed and acceleration data being available. Here too the optronic suite includes a day camera, with detection/recognition/identification ranges of 13.4/6.5/3.7 km, while the thermal camera provides DRI of 11.4/7.4/3 km, a laser rangefinder with a 12 km range ensuring target distance measuring.

As for the two-man turret, this will lack the Hunter-Hunter mode, will be ready for adding two antitank missiles, one per side, and will feature a number of survivability systems, first of all a Level 4 ballistic protection kit, which will bring its mass up to 2,500 kg without ammunition, which in this case will be up to 230. It will feature the NATO Generic Vehicle Architecture (NGVA). Leonardo considers with interest the Italian Navy VBA wheeled amphibious vehicles programme, which second batch should include fire support vehicle, the unmanned version being a perfect fit. As for the two-man version, this eyes the programme for the Italian Army future armoured infantry fighting vehicle, known as A2CS (Army Armoured Combat System, formerly AICS). Although mock-ups are already there, the first HITFIST prototype turret should be available a few months after the Lionfish, as potential programmes should materialise at a later moment compared to naval ones.

Photos and graphics courtesy Leonardo