WDS 2024 – MARSS Interceptor MR killer-drone close to production

Unveiled at the first edition of the World Defense Show, the Interceptor killer-drone is close to enter serial production, MARSS unveiled at this year edition of the Riyadh exhibition

“We are not yet to the market, but we will start deliveries to our customers in Q3/Q4 this year,” Johannes Pinl, CEO and founder of the MARSS Group tells EDR On-Line on the company stand at the second edition of the World Defense Show.

On the company booth stands a model of the Interceptor MR, the Medium Range version of the company killer-drone, the two-letter acronym having been added to the system name as now an SR, Short Range, version is in advanced phase of development, while the LR, Long Range system is for the time being on hold, full priority being given to the industrialisation of the MR and the development of the SR, the latter meant for integration into armoured vehicles.

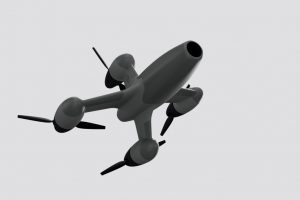

Compared to the model seen two years ago the Interceptor MR has considerably changed. Ducted propellers have been replaced by larger two foldable-blade propellers. “We originally selected the ducted solution as this has optimal performances at high speed and also better safety and better survivability when hitting Class 1 UAS, however it gave some problems in the vertical take-off phase,” Mr. Pinl explains,” therefore we decided to move to open propellers. “These not only provide better performances in VTOL but also allowed us to reach a higher speed, maximum seed being now 80 m/s.” Being the Interceptor MR terminal effect based on kinetic energy delivered to the target, the higher speed is a key design parameter, and touching a Class 1 UAS with the titanium-reinforced leading edge of one of the four wings of the Interceptor MR might cause devastating damages to the target. Build mostly in carbon fibre, the airframe of the MARSS Group is reinforces with titanium inserts in those places meant to hit the incoming UAS.

During the meeting with Mr. Pinl EDR On-Line understood that for ensuring high rate mass production, something that has become of paramount importance considering lessons learned from the Ukraine war, the body of the Interceptor can also be produced by 3D printing. Stiffness is lower when produced with such method, mass remains the same, only a few grams difference, as thickness must be increased in certain areas, and obviously the airframe is less survivable and does not ensure a multi-mission capability against a Class 1 UAS, the carbon fibre version being considered able to reiterate its attack against different target at least three times. The huge advantage is however the production rate, which can be increased dramatically. Production wise, MARSS will produce its Interceptor MR in its two facilities, one in the United Kingdom, in Bristol, and one in the Kingdom of Saudi Arabia, in Riyadh, the former to respond to European and NATO customers contracts, the latter to Middle East countries contracts.

Back to the system description, the original version was fitted with four electric DC brushless motors, two bigger and two smaller. Now the four motors are the same, bigger and more powerful, and drive the two-blade propellers; in order to increase the system survivability at impact the motors are stopped immediately before hitting the target and blades are folded, the motors automatically restarting after the hit, blades extending due to centrifugal force.

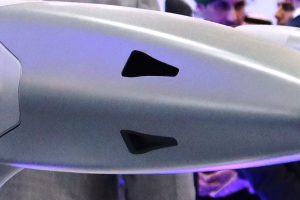

While the Interceptor MR flies towards its target under the supervision of the command and control system, its data link ensuring connection to the NiDAR CORE / NiDAR C2 system by the same MARSS, once the attack is authorised by the man-in-the-loop, in the last phase of the attack it operates in fully autonomous mode under the guidance of the on-board processing unit that contains artificial intelligence-based algorithms and receives target data from the uncooled infrared imaging sensor installed in the nose. In the final configuration air intakes are visible, the air flux being used to cool the high performance computer processing unit. “The attack phase starts at around 1 km away from the incoming target,” Mr. Pinl tells EDR On-Line, interception range being over 5 km, maximum altitude being 2,000 metres.

The Interceptor MR is 800 mm long and has a 900 mm wingspan; the new configuration brought to a marginal reduction in mass, the system weighing now short of 8 kg. The airframe can carry an extra kilogram payload, for example a miniaturised electronic warfare package that would be activated ay short distance from the targeted drone, required energy being therefore minimal. Dimensions dictate the size of the launcher, a model of a trailer with a six-cell launcher being exhibited at WDS. Each canister is climate controlled, ensures battery recharging, diagnostic and the link to the C2 system. The shape is different from that seen two years ago, which was an early development item, the canister being 140×110 cm. EDR On-Line understood that the cold launch system is not pneumatic but rather exploits an electromagnetic catapult, similar to a rail gun, which ensures a very long shelf life.

The trailer mounted model is a notional solution; as each canister is independent, MARSS is ready to produce customised launchers for its customers with different numbers of canister, also included a mast-mounted surveillance suite with four AESA radar antennas, looking very much like the aCHR (Advanced Compact Hemispheric Radar) from DRS RADA Technologies, used in many C-UAS systems, and a single optronic gimbal. The trailer also carried six spare Interceptors, which brings to 12 the system capacity. Considering the three-kill capability of the Interceptor MR, this means that the trailer can engage over 30 targets, if these are all Class 1 UAS. We should not forget that the MARSS system is capable to abort mission, come back to base and land vertically. Another difference from the past is that now for safety reasons a parachute has been added at the rear of the airframe, which might be deployed in emergency situations.

The system being near ready, it will be interesting to see how the customers will use it in terms of CONOPS, swarming, multiple missions to ensure maximum kill probability, with the following Interceptors providing battle damage assessment and eventually reiterating the attack, and so on, the latter case being probably suitable when dealing with bigger UASs.

Switching to the smaller system, the Interceptor SR, this is considerably smaller, with a 1.5 kg mass, a 400 mm wingspan and a 250 mm length. “With our medium range solution at TRL 8+,” the company CEO tells EDR On-Line, “many technological bricks can be downloaded to the short range system, especially software ones.” This allows starting from a TRL 5-6 level, shortening development times. The Interceptor SR will have an interception range of over 1 km, a maximum altitude of over 500 meters over ground, and a maximum speed of 60 m/s. Being designed as a last-ditch defence for armoured vehicles, a very quick reaction time is required, the company indicating a less than 3 seconds figure. Automation is a must as no time should be lost, hence detection, classification and command and control functions are fully autonomous.

The airframe will be pretty similar to that of the bigger system, although EDR On-Line understood that the configuration is not yet frozen. Considering its dimensions the Interceptor SR will be capable of one-way missions only, without the multi-mission capacity of its bigger brother, and will be capable to engage only Cat. 1 targets. Beside the use on board armoured vehicles, an infantry launched version is also being considered.

The Interceptor SR should be ready for testing in Q1 2025, MARSS aiming at unveiling it at IDEX next year.

Photos courtesy MARSS and P. Valpolini