Saab further develops its knowledge in warhead technology

One of the reasons for which Saab acquired what was then RUAG Warheads back in 2007 was linked to a weapon that is currently on newspapers’ front pages, the NLAW (Next generation Light Anti-tank Weapon). Its shaped charge warhead, which is detonated downwards when the missile overflies its target in the OTA (Overfly Top Attack) mode, was designed, developed and manufactured in Thun, some 25 km south-west of Bern, the Helvetic Confederation capital. Within Saab´s Business Unit Ground Combat there is the department SBDS (Saab Bofors Dynamics Switzerland Ltd). SBDS in short, has since then been integrated into Saab, which allows it to exploit synergies within the Swedish group’s research and technology laboratories. In a rapidly changing world, the company’s approach to warhead development allows it to quickly adapt its designs to customers’ requirements thanks to a set of evolving and increasing of technologies that constitute the building blocks on which new designs are based.

“We considered multipurpose warheads to become the priority, however due to the current situation the focus is shifting to antitank at present,” Christopher Leitner, Head of Marketing and Sales at Saab Bofors Dynamics Switzerland tells EDR On-Line. Antitank warheads have been the bread and butter for a long time for the company, however this does not mean that Saab will rule out the multipurpose theme, as it is currently developing lightweight warheads of this type i.e. for loitering munitions or other weight sensitive applications.

At Saab products can be divided by the type of target set, such as: anti-tank, anti-air, anti-bunker or multirole. For cost / performance, there are state of the art warheads at a medium price range for unguided shoulder launched systems, and high-end warheads that include the latest technology destined for top-tier missile systems in the anti-tank as well as in the air defence fields.

The Thun-based company is providing its warheads to numerous OEMs; due to the reduced numbers of systems produced, some top-tier missiles manufacturers have outsourced their warhead production capability, hence these are now designed and manufactured by a small community of companies Saab is the leading one in Europe for small calibre systems, up to 3,500 mm diameter. Starting from antitank systems, here the shaped charge remains the dominant player. One of the key parameters is the penetration capability versus the diameter of the main hollow charge, known as CD. In the past the CD 10 limit (penetration 10 times the charge diameter) seemed the very limit, but this has already been overcome, Saab’s warhead developed for MBDA’s Milan ER in the early 2000s being around CD 12. “The trend is to go for CD 15,” Christopher Leitner says. Reaching that limit would provide a flexibility that will allow increasing penetration while maintaining or even reducing weight, eventually adding fragmentation elements, hence giving birth to a missile that can deal with different targets; having in service a single missile that covers all missions in a certain envelope would definitely reduce the logistic footprint and the training, therefore cost of ownership. New materiel and new explosives are definitely part of the CD increase. Today all missiles warheads are produced following Insensitive Munition (IM) criteria, the key element being IM explosive; this is not the case for mortar bombs, a considerable market share still requiring non-IM ammunition loaded with COMP B or TNT (Trinitrotoluene) even in Western Europe.

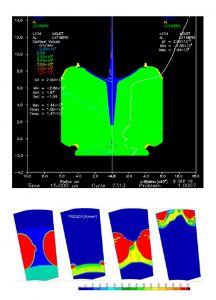

IM explosive has inherently less energetic density, as part of it is made of non-explosive materiel, that provides its insensitive properties. “One of the most used IM explosives is the PBXW-11 of which 96% is made of HMX with only 4% of non-energetic materiel, and it is quite easy to compensate that small energy loss by optimising the warhead design,” Christian Herren, the company Director Development and Quality tells EDR On-Line. Fully accepted in most European countries, except in Germany where higher insensitive qualities are required by the Bundeswehr, the PBXW-11 is at the base of most Saab warheads, such as that of the 5th generation MMP developed by MBDA. “We have proven that using that explosive we can reach CD 11-12 by improving the warhead design, and we are pushing further.” However when some nations, or some services, mostly navies, need higher IM properties, things change. To reach this objective only 86-87% of the fill is made of energetic materiel, and optimising the design allows to recover around 10% of the loss, hence we only have a 5-7% reduction in performance,” Christian Herren says.

Knowing Christian Herren’s knowledge of chemistry and more specifically in explosives, EDR On-Line asked him to share some considerations on developments in the explosive field. “I see two trends in that field. The first one is by research institutes that are looking for new formulas for explosives but there we are mostly at the end of the line. There are of course molecules that can have an impact on penetration performances, but in terms of a few percent, and some of those substances cost thousands of Euros per kilogram, so they will never be used in mass series production. They may be employed only for very specific uses, i.e. nuclear devices. Currently what we have is PBXW-11 and PBXW-17, and this is what we have to work with,” he states. “There are however other things we can do, such as better understanding the complex physical chemistry which is behind those explosives.

We started to simulate that in a quantum mechanical approach and that gives a lot of surprises and possibilities that in perspective will allow making the production process cheaper and more efficient. As an example, when using isostatic pressing, which is currently the standard production process for high-end warheads, one of the big costs comes from the loss of explosive when machining the explosive. We are therefore working hardly to understand how we could use the material in a more efficient way and maybe how to recycle the scrap material, which would in the end make the warhead cheaper.”

Another line Christian Herren sees becoming increasingly adopted internationally is that of replacing non-IM explosives such as TNT or COMP B, with explosives that include NTO (Nitrotriazolone) and that will be much better in terms of IM properties but not significantly more expensive. As previously stated, cost led many nations to stick to non-IM rounds in certain categories, with these new explosives able to bridge the gap for mass production rounds.

A key player in the optimisation process is definitely simulation; “we are using neuronal networks, and we are working massively on artificial intelligence that helps us in designing the liner profile,” Christopher Leitner explains. Some profiles are impossible to be produced, while other can become reality, and usually they are almost similar to those designed by Saab’s scientists. To penetrate the main armour of a Main Battle Tank (MBT) the jet generated by the shaped charge must first of all reach it. To do so, something else must take care of the Explosive Reactive Armour (ERA) that nowadays is installed on most MBTs. “We developed different technologies able to do that, one in a detonating way and two in a non-detonating way, in which you go through the ERA without exploding it. This can be done in an energetic or in a kinetic way,” Mr. Leitner tells EDR On-Line. The advantage non-detonating solutions will have is to avoid creating major turmoil in front of the main charge. No details were provided on how the non-detonating energetic solution works, but it is based apparently on a shaped charge. As for the kinetic solution, this very much resembles the Modular Explosive Penetrator (MEP) developed in Thun when the company was still RUAG Warheads, and at that time used in an RPG prototype aimed at penetrating sandbags and walls. The kinetic solution maintains the MEP conical forward shape, with its surface treatment remaining undisclosed. Moreover, it should also maintain some capabilities in terms of wall penetration, which leads to a potentially multipurpose solution.

Modularity is the keyword in Thun, and EDR On-Line was shown the scheme of a multipurpose solution that includes a series of elements designed to neutralise ERA and then the main armour, while maintaining also a multirole function. Before firing, the operator can select the mode best suited for the target, which adds considerable flexibility to the missile. All technologies involved are at TRL9.

And this brings us to the fragment generation, which added to antitank capabilities allows a dedicated missile to transform into a multipurpose one. Some of those are well known and have been in use for some time, such as MAPAM (Mortar Anti Personnel Anti Material) used in mortar rounds, and Skjoll, which comes in the form of a belt added outside the warhead generating fragments with adaptable energy and adaptable spray angle, able to deal with soft targets. It is based on very small diameter tungsten balls, with adaptation to customer needs being obtained by modifying the wave shape and balls materiel. These two technologies have been patented and are already in use in some of the warheads provided by Saab to its customers. The third fragment technology patented by SBDS is named Thor, and is a further development of the MAPAM that features multi-materiel and multi-geometry characteristics.

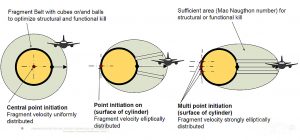

One more patent is part of the SBDS technology portfolio, although this one is not yet available at production level. Named ExploStrain, it is based on multiple initiation points; using smart fuses available on the market, it is possible to initiate the explosive in a way to concentrate fragments on one side at an angle, increasing by 40% the warhead effectiveness. Currently considered at TRL 4-5, it would allow to either increase effectiveness or reduce the warhead weight while maintaining the same effectiveness of a conventional one. The ExploStrain technology is considered particularly suitable for air defence missiles, as it will allow triggering the warhead in the best relative position to the target, orienting the majority of the fragments towards the intercepted airframe. “It is relatively simple as many missile seekers provide not only the relative special position of the target relative to the missile but also the rotation of the latter,” Christian Herren says.

Concentrating fragments is also the aim of a still unnamed technology that exploits two initiation points. When the shock wave is the outcome of the detonation initiated in a single point, it pushes forward fragments within a cone of about 7°, which at some distance would mean a lesser fragment density hence a loss of performance. Christian Herren explains to EDR On-Line. “With our technology, detonating the explosive in two different points allows focusing the fragments which in a missile aimed at aerial targets can increase effectiveness by 30%,” he adds.

However, fragments concentration can be also obtained with other means than working on initiating points. “Diffgeo is the acronym for differential geometry, and it is based on mathematical calculation that allows optimising shrapnel focusing, exploiting only the geometrical shape of the fragmenting surface,” So this would not be the typical cylinder but a warhead surface optimised to build a focus line. This is a system that Christian Herren considers simpler that the dual-point initiation one, adding that Saab has already produced and tested some systems based on that technology.

One technology that goes together with dual-point initiation is Diabolo shape as it is a symmetric shape, but by combining the initiation technology with the geometry it can reach a very high concentration of fragments. “This is used to defeat hard aerial target samples, such as those considered by various customers that retain heavy maraging steel tubes that have to be cut,” explains Herren, underlining that Diabolo shape is the main candidate for future air defence or air-to-air missiles warheads under development.

As for Blast Shield, this is an enhanced blast solution that blends into a multipurpose warhead and it is used when the main effect required is more a pressure wave than fragments; used in combination with ExploStrain, it is possible to focus the blast in the same way the latter does when coupled to a fragment generation technology.

However, in Thun scientists and engineers are not exploiting those technologies only to allow increasing warheads effectiveness. Deepening their knowledge on the intimate mechanisms of a warhead also allows them to better understand which are the areas where extreme precision is required, and which are those where a lesser accuracy has minimal influence on performance. “At CD 14-15 charges, 40% of the cost will be purely linked to the quality level of manufacturing, hence this better understanding of warheads mechanisms allows us to reduce cost by 15-20% therefore maintaining an excellent performance-to-price ratio,” Christopher Leitner underlines.

Beside missiles and mortar ammunition, which currently represent the great majority of the SBDS business, the warhead-wing of Saab is looking to new applications such as to Loitering Munitions (LM) or Unmanned Ground Vehicles (UGV) domains. Especially for LMs, the weight issue is a critical factor and, until now, most such systems have been fitted with existing warheads that were not optimised for such use. SBDS is looking at two main market areas, Europe and North America, where many nations in those regions have adopted LMs in their inventories. However, this might change drastically in the coming 5-10 years. When numbers increase, companies producing LMs will probably decide to invest in warheads capable of dealing with most types of targets, which are one of Saab specialties, and which would leverage the technological research done to now.

According to Saab, the LM business will probably have a more unified approach compared to the purpose-made warheads for missiles. As for UGVs, the aim is to create effectors that might range from lethal to less-than-lethal solutions, which might even extend in the firefighting domain thereby avoiding putting human beings in hazardous situations.

Images and photos courtesy Saab