Sherpa A2M: mobile protected indirect firepower from Arquus, NTGS and Thales

Visiting the Arquus booth at Eurosatory 2022 one brand new product attracts the eye. This is the Mobile Protected Mortar System, based on a Sherpa Scout chassis, also known as A2M for Advanced Mobile Mortar. .

The weapon system mass being well within the vehicle payload limit, this allows the Sherpa to keep all its characteristics in terms of mobility and protection. It maintains the four-door cabin, which level can be adapted to customers’ needs thanks to modular armour packages, residual payload allowing bringing it to the maximum accepted level. The same applies for the mine and IED protection underbelly. The protected bonnet and run-flat inserts ensure good mobility resilience even under attack, the 150 kg bonnet being beneficial to weight distribution.

The vehicle rear flatbed is fitted with the auto-aiming deployable mortar system developed and produced by New Technologies Global Systems (NTGS) of Spain. In travel order the mortar barrel lies horizontally on the vehicle; when deployed, the weapon system is pushed back until the vertical strut that sustains the mortar platform is able to rotate 90° in order to lower the platform on the soil. This means that all recoil forces will be absorbed by the ground, which means that no modification must be carried out on Sherpa suspensions. A motorised arm allows varying the elevation from 45° to 80°, according to the firing data provided by the Fire Control System (FCS). It also allows rotating on the barrel on the x-y plane orienting it in azimuth within a ±60° arc. On the two sides of the vehicle, close to the cabin, we find the ammunition racks, which in the configuration unveiled at can host up to 36 rounds and charges, however EDR On-Line understood that up to 40 rounds could be fitted adopting a slightly different configuration. The two following cabinets host an auxiliary power unit that powers the hydraulic pump that allows the system deployment and redeployment.

While capable to be fitted with various 120 mm and 81 mm barrels, Arquus made the choice of teaming with Thales to provide a high-end solution to its customers, thanks to the superior performances of the 120 mm rifled mortar compared to smoothbore tubes. In service with many nations both in the towed version and in the 2R2M automated mounted mortar system, this barrel now finds a new usage on a lightweight mobile mortar system, the lightest such system fitted with a rifled barrel according to Arquus. The Arquus/NTGS/Thales A2M will be fitted with the Vali-ECSFire Control System specifically designed for indirect fire support systems and already installed on M109 self-propelled howitzers. While some configuration of the NTGS mortar system see the FCS interface installed in the right cabinet, the display allowing the commander to choose the target and initiate the aiming process being on the outside wall, in the Arquus/Thales solution this will be installed in front of the commander’s seat inside the protected cabin. This will obviously be updated with the data relevant to the Thales rifled tube and the ammunition, also provided by Thales. Overall the 120 mm rifled mortar system will not only increase the range compared to smoothbore solutions, but also provide better accuracy and an increased terminal effect.

According to Arquus integrating the NTGS deployable mortar system into the Sherpa Scout was relatively simple, the mortar system being self-sufficient in terms of energy, while the transport configuration allows the centre of gravity to fall within the limits of the vehicle design, hence the mobility remains unaffected. Now qualified at 11,500 kg combat mass, the vehicle payload allows installing a light remotely controlled weapon station (RCWS) on top of the roof, providing a considerable self-protection capability. Not only, should a target be in line of sight, it is possible to exploit the RCWS optronic package to feed its grids into the Vali-ECS and call a fire mission. The fact that the NTGS deployable mortar system is self-sufficient in terms of power generation leaves the power produced by the vehicle 350 A generator for on-board subsystems, such as jammers, etc.

Arquus and Thales have assembled the prototype vehicle, which carried out some mobility and deployment tests in Spain, no firing tests having yet been made. Eurosatory marks the launch event for the system; EDR On-Line understood that Thales would be the prime in bids throughout the world.

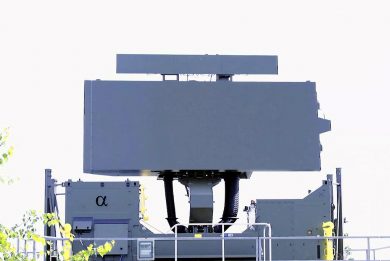

Photos courtesy Arquus and P. Valpolini