SMArt is back!

In the 1980s the overwhelming number of Warsaw Pact tanks led some western countries to develop artillery ammunition capable to destroy MBTs. In December 2008 the Convention on Cluster Munitions (CCM) was signed in Oslo; this prohibited to use, stockpile, produce and transfer cluster munitions. It became effective on 1st August 2010, about 120 states having committed to it. It is to note that the US did not sign the CCM, however its national regulations on that subject are even more stringent than those included in the international agreement. CCM’s Article 2.2 (c) defined five criteria to be fulfilled in order that a weapon would not be categorised as a cluster munition: each munition should contain fewer than ten explosive submunitions; each explosive submunition should weigh more than four kilograms; each explosive submunition should be designed to detect and engage a single target object; each explosive submunition should be equipped with an electronic self-destruction mechanism; each explosive submunition should be equipped with an electronic self-deactivating feature. Considering all those conditions, the SMArt155 (Suchzünder Munition für die Artillerie 155, Sensor fused Munition for 155 mm Artillery), a round developed by GIWS (Gesellschaft für Intelligente Wirksysteme mbH), a 50/50 joint venture created by Diehl Defence and Rheinmetall Weapon Munition, did not fall into the Cluster Munitions category. This was not true for DPICMs (Dual Purpose Improved Conventional Munition), which were banned, so with the increased probability of conventional scenarios, after years of nearly asymmetrical-only issues, considerations about bringing the SMArt155 back among the company portfolio made their way at Rheinmetall. Compatible with all 39- and 52-calibre artillery systems respecting the Joint Ballistics Memorandum of Understanding, and capable to defeat main battle tanks and infantry fighting vehicles by top attack, the SMArt155 proved that its dud rate is much less than 1%. In the 1999-2012 timeframe 331 rounds were fired by the two original customers, Germany and Switzerland, beside the qualification rounds, showing a dud rate of less than 0.6%, which makes it well within today requirements for a DPICM replacement. In fact the dud rate might have been even lower should the last safety mechanism have not been set in the “off” position for range safety reasons.

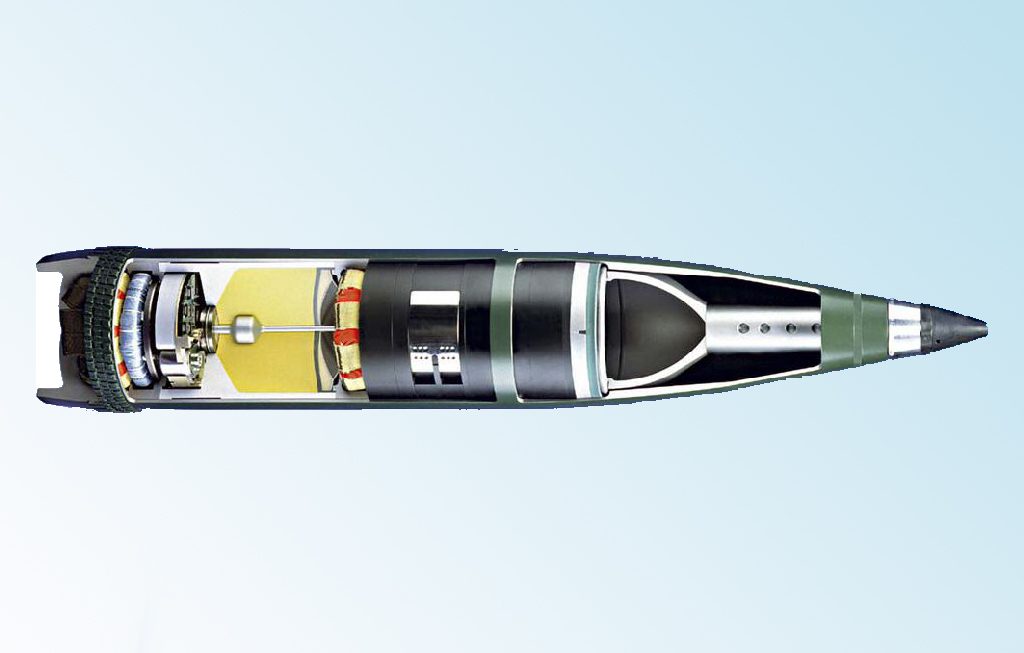

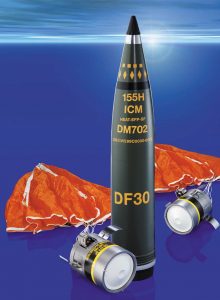

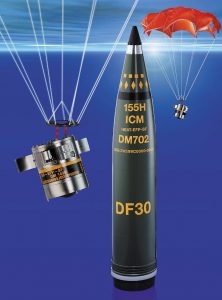

As the production of the SMArt155 round, known as DM702A1 in the German Army, was ceased in 2004, following the completion of the contracts with Australia, Germany, Greece and Sweden, for over 12,000 rounds, it is worthwhile describing shortly the system. The 155 mm round is fitted with the GM52A1 time fuse, located at the front, followed by the ejection unit and by the two submunitions, a base plate closing the round at the rear. The fuse timing is set prior to loading, then the SMArt155 is used as any standard ammunition and fired. Once the time set in the main fuse has elapsed, the ejection charges separate the body from the two submunitions, which batteries are then activated. As the round falls at around 300 m/s, with a spin rate of 200 spin/second, it has to be slowed down, this function being devoted to a ballute, a mix of a balloon and a parachute, the spin rate being reduced to 3 spin/second, the axis of the submunition being angled 30° from the vertical, allowing the sensors to cover a wide area.

Only when the ballute is fully deployed, the submunition is fully armed and the three sensors, one active radar also used as range measuring device, one passive radar based on the measure of the reflection of space waves on the ground, and one infrared sensor, are activated and start searching for targets; search is usually carried out between 200-15 meters and 20 meters from the ground. When a target is identified the aim point is calculated and the submunition is fired. It is made of a shaped charge with a tantalum liner that generates an explosively formed penetrator capable of defeating a 120 mm rolled homogeneous armour. Considering that the EFP would hit the roof of the vehicle, typically not the most heavily armoured area, this is still considered sufficient even against nowadays tanks. To counter such threat the adoption of passive or reactive armour on top of the turret and chassis would add considerable weight to the vehicles, installing ERA tiles meaning in many cases strengthening the roof itself to withstand the effect of their explosion. The adoption of active measures would mean first adding systems capable to search and track the incoming submunitions, a quite expensive option to which we must add the cost of the effectors.

Should the submunition not find a target, the first electronic self-destruct mechanism, based on the active radar sensor being used as radar altimeter would detonate it a second self-destruct system, the battery power down function, being activated at 0 meters height.

In late 2017 market considerations led to the decision to reactivate the GIWS activities and plan the restart of the SMArt155 production. The move proved successful as the round attracted considerable interest at Eurosatory 2018. According to estimates made by the German Army Artillery School, a counter-battery mission against 18 enemy artillery systems, grouped in two clusters of six and two of three, would need over 20,000 DPICM/HE rounds versus less than 150 SMArt155 rounds, with considerable benefits in terms of reduced collateral damages, mission time, logistic burden, barrel wear, charge and fuse consumption, and storage costs.

The roadmap for restarting the production is subdivided in four phases. The first one started in late 2017 and will last two years; this time is being used to find the obsolescent components, which are not available anymore, and identify their replacements. Phase two, which will start in late 2019 and will last until 2022, will be dedicated to engineering and manufacturing, eliminating obsolescence and integrating the new components into the production cycle. In 2022-23 the JV will carry on the qualification process with the German BAAINBw, production being scheduled to start in 2024. GIWS is also looking at the ammunition growth potential; old chip could process only a limited number of data, while those available two decades later are much more powerful and might provide i.e. a much better precision in height measurement.