The new generation digital native FDI/Belh@rra frigate

Belh@rra frigate: to satisfy both the French Navy requirements and the growing request of international customers for a heavily armed 4,500 tonnes frigate.

Unveiled for the first time at Euronaval 2016, the previously known Frégatede Taille Intermédiaire (FTI) mid-size frigate was renamed Fregate de Defense et d’Intervention (FDI) or Belh@rra for the international market, was developed by Naval Group to satisfy both the French Navy requirements to deploy five new “first-rank” frigates by 2030, and the growing request of international customers for a heavily armed 4,500 tonnes frigate. The central role of the FDI/Belh@rra export based-design and the Gowind corvette families in the next 10-15 years’ worldwide export market has been underlined by Naval Group CEO Hervé Guillou also during the first steel cut ceremony of the first of class.

The Belh@rra’s detailed design activities were launched one year ago

After the initial feasibility studies launch in 2015, the DGA, the French Navy and the industrial team led by Naval Group, and including Thales and MBDA, have begun to work co-located as a single integrated team with the result, among others, of a better understanding of mutual needs, a progressive validation of solutions and a better reaction to requests. “If the deadlines are met, …. it is also, I believe, thanks to the collaborative work between the DGA, the Navy and the Naval Group that was set up for the FDI……And I hope this will extend to all our weapon programmes. That’s why a few days ago at Balard I inaugurated a collaborative platform between the capacity division of the Army Staff and the DGA’s future systems preparation and architecture department … welcoming industrial representatives”, Florence Parly, the French Minister of the Armed Forces, said at the ceremony. In April 2017 this led the French Direction Générale de l’Armement (DGA) to notify Naval Group (acting as prime contractor and combat system integrator) and Thales the development and construction contract for the first FDI, and on October 2017 to notify MBDA the development and production contract for the new generation multi-weapon systems firing installation. The FDI’s detailed design activities were launched one year ago, and a critical design review (CDR) of the FDI was achieved last May. In parallel, the industrial team led by Naval Group, – employing around 800 persons among all its industrial sites, including 400 subcontractor companies (200 contracts awarded), began to work on the programme, which according to Naval Group CEO will see the first-of-class sea trials start in October 2022 for a delivery one year later. The new ship will then be subjected to an operational test and evaluation phase by the French Navy and the DGA to become fully operational in 2025. Other suppliers for the programme include Safran, MTU, iXblue, Axima, CNIM/Bertin, Leonardo and Nexter.

“The Belh@rra is 100% developed under 3D design”

As the neuralgic centre for surface ships’ design and integration, Naval Group’s Lorient facility is responsible for overall ship design and programme management, development and integration of platform and navigation systems, shore integration platform for ship conducting, shipbuilding and sea trials, the Nantes-Indret site being focused on the propulsion, that of Bagneux on combat system integration, the Angouleme-Ruelle plant on ship equipment while the Ollioules site (near Toulon) manages the combat system, data centres and cyber security development. According to Naval Group’s Surface Ships Business Development and Sales Marketing Manager Hervé Boy, the FDI design and development is requiring one million hours while one more million is planned for the production of each ship at the Lorient site, with 18 months on average required between each ship delivery. “The FDI is 100% developed under 3D design, making it the first Naval Group paperless shipbuilding programme”, Boy highlighted. In addition to the collaborative effort between the DGA, the Navy and the industry, Naval Group made significant investments on the design and production line to speed up ships delivery.

The French MoD’s DGA tests, evaluates and certifies the combat management system (CMS)

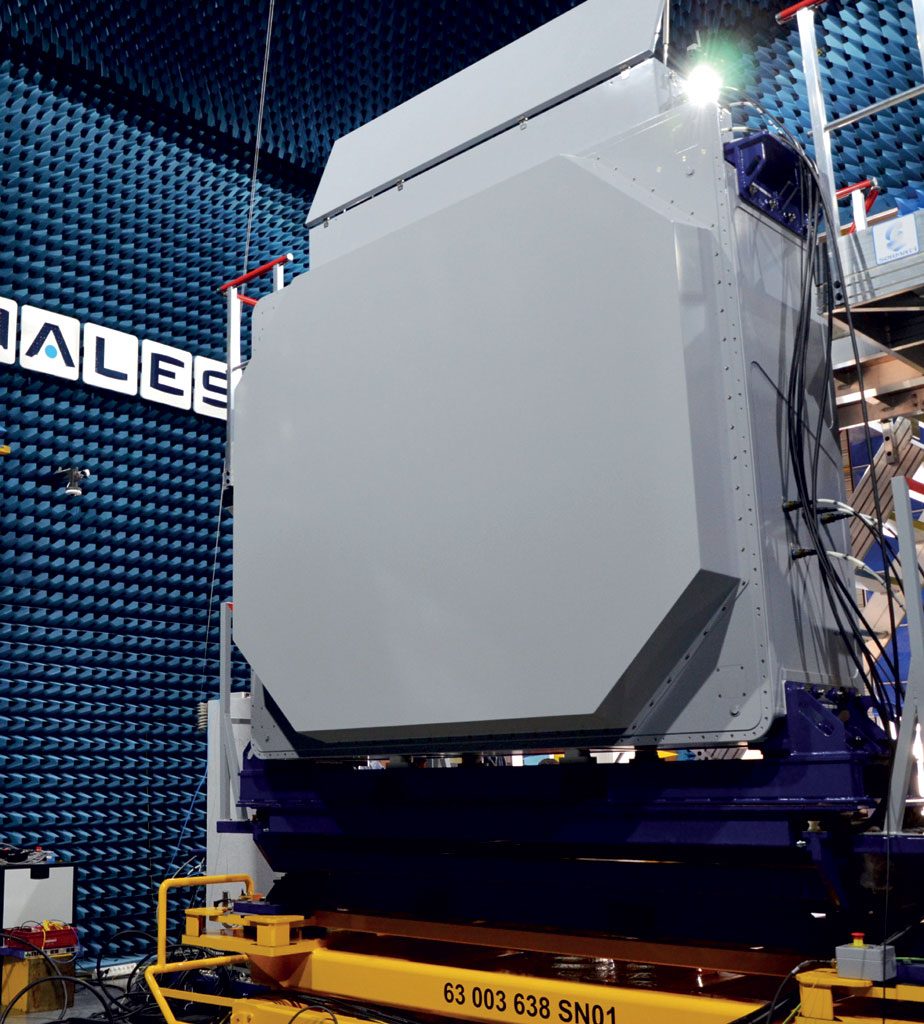

Naval Group has also established two Shore Integration Facilities (SIF) respectively devoted to the new generation combat system development with the latest generation SETIS combat management system (CMS) version and to the ship digital backbone with data centres and integrated bridge at Ollioules, the latter to be operational soon. The French MoD’s DGA tests, evaluates and certifies the CMS and its sensors suite, before singularly and them together at SESDA (Site d’Expérimentation des Systèmes de Défense Aérienne) SIF in Saint Mandrier, near Toulon. A full replica of the ship integrated mast module upper-section with the sensors’ suite centered on the newly-developed Thales fully-digital four fixed-faces (4 FF) Sea Fire Active Electronically Scanned Array (AESA) multifunction radar will support the DGA and French Navy activities. The new radar’s single face has emitted at full power on September 2019 at the SESDA facility and will evolve in a complete suite, integrated with MBDA air defence missile system.

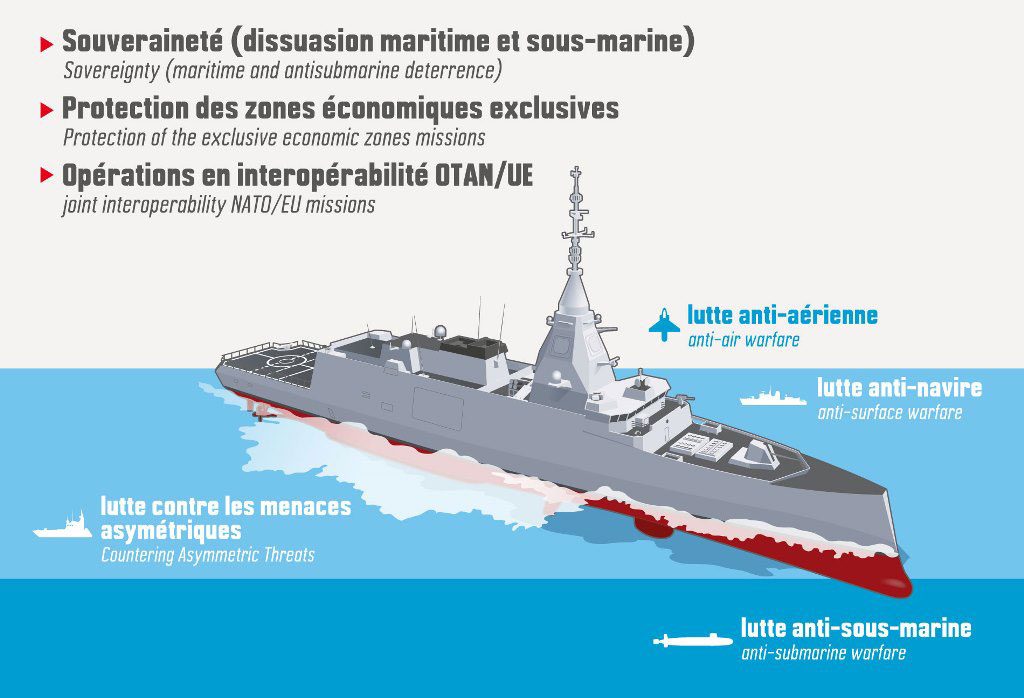

The French Navy’s FDI/Belh@rra platform design

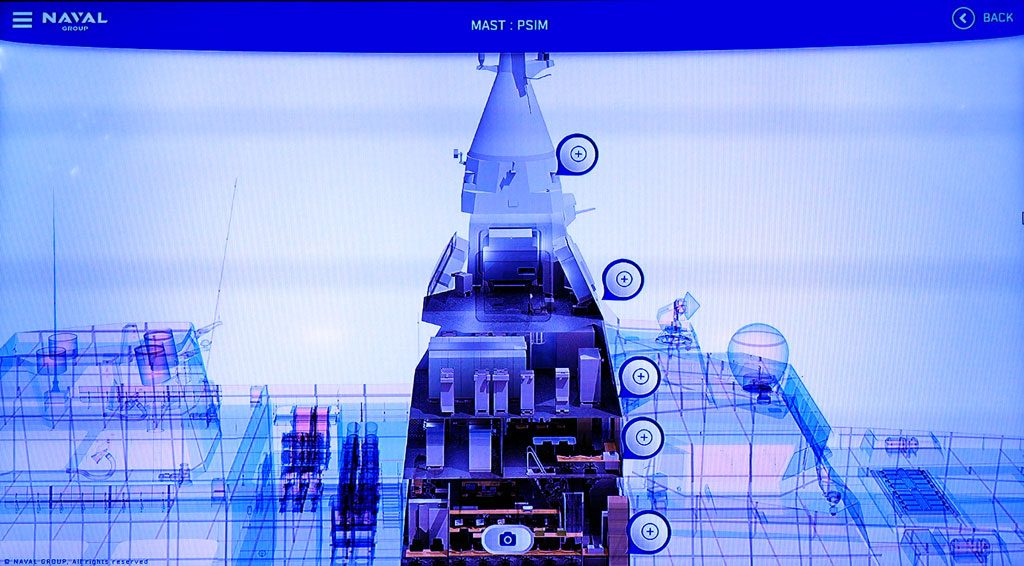

Capable to be employed in all warfare domains including anti-air, anti-surface and anti-submarine warfare and special forces support operations, the FDI was developed to be capable of conducting a wide range of missions, from high-level warfighting to maritime interdiction operations and crisis prevention. The French Navy’s FDI/Belh@rra platform design is based on large steel-made platform of around 4,400 tonnes full-load displacement, 121.6 meters long with a 17.7 meters beam, with an “inverted bow” design intended to improve seakeeping in high sea states and provide higher speed compared to a traditional hull, according to DGA. The FDI features a single superstructure block interspersed by the area for the anti-ship missiles launcher canisters laterally hided to reduce the platform radar signature and including the accommodation area for the Panoramic Sensors and Intelligence Mast (PSIM) “macro-module”. Although already applied to the Gowind corvette type, the latter represents a novelty for frigate-class platforms and for the French Navy. Larger and heavier than the corvette-type assembly, the FDI’s PSIM single pre-outfitted, multideck steel structure integrates above-water sensors, equipment rooms, and the command information centre (CIC) in addition to one of the new-generation frigate’s digital infrastructure’s backbone data centres and a C2 planning room for flagship duties. The entire PSIM module is built and outfitted apart from the ship platform, then craned on board for integration as a single monolithic unit, reducing overall ship delivery time.

The FDI/Belh@rra will be powered by a 32-MW CODAD (Combined Diesel And Diesel) propulsion package

Naval Group has however designed the FDI/Belh@rra platform to be modular and scalable with the possibility to introduce hull-middle sections up to 9 meters to satisfy potential export customers’ requirements for additional space, for example to accommodate a mission bay. Differently from the FREMM larger ASW-dedicated platform, equipped with a quite but, by design, complex CODLOG (Combined Diesel and electric Or Gas), the FDI will be powered by a simpler and more economical 32-MW CODAD (Combined Diesel And Diesel) propulsion package based on four MTU16V8000M91L diesel engines, each providing 8 MW, allowing to reach a maximum speed in excess of 27 knots, while the range stands at 5,000 nautical miles at cruise speed. The two engine rooms, accommodating two diesels each connected through gearbox to one of the two ship’s shafts with controllable pitch propeller (CPP), are separated by an armoured bulkhead to physically divide the two damage control zones of the ship and the propulsion package, to ensure survivability in case of damage or impact on one zone. Thanks to the same platform design flexibility, the ‘export’ design could accommodate a more powerful 10 MW diesels-based propulsion package capable to achieve 29 knots. The platform and combat systems electrical power requirements are satisfied by six Scania 500 kW gensets to which a seventh emergency unit is added on the upper deck.

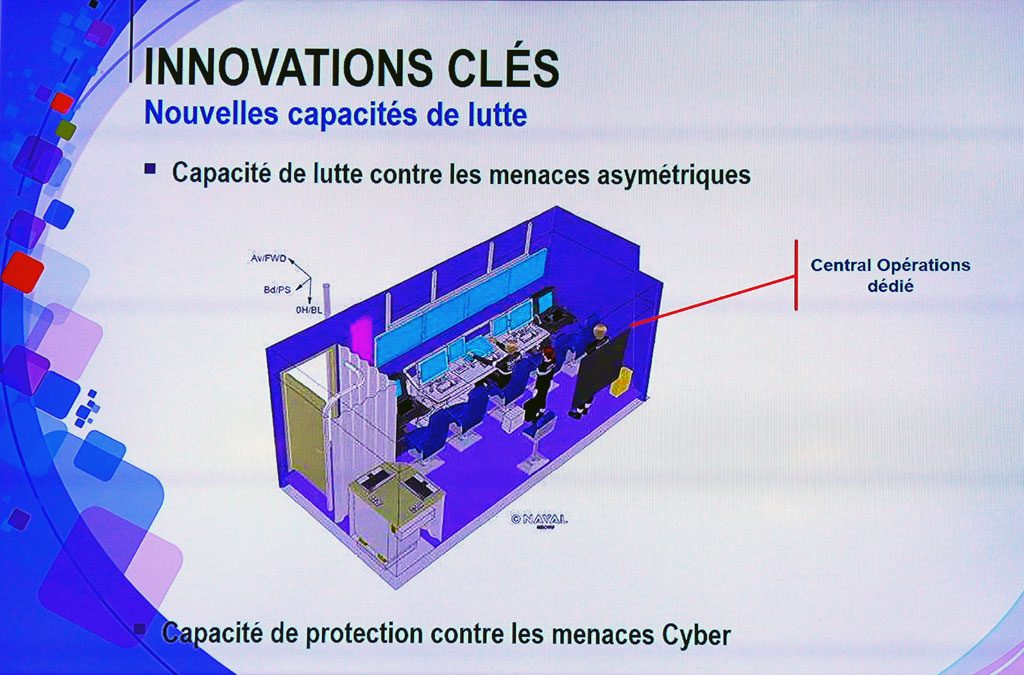

In addition to the PSIM, the FDI’s digital native design introduced for the first time on a French Navy’s warship is centred on a ship’s platform and combat system data infrastructure based on two data centres, a cyber management system to protect the whole ship, a new asymmetric warfare combat centre (PCLCMA, PC de Lutte Contre les Menace Asymétrique) or ‘digital combat bridge’ and a new generation SETIS command management system version, in addition to an advanced sensors and weapon systems suite centred on the newly-designed Thales fully-digital four fixed-faces 4 FF AESA multifunction radar, a new EW suite, a new tactical picture and tracks raw data fusion, cooperative surveillance capability named as Veille Cooperative Navale (VCN) (previously known as Tenue de Situation Multi-Plateforme) by the French Navy (similar to the US Navy Cooperative Engagement Capability) and an aviation detachment incorporating for the first time since the design phase an unmanned air system fully integrated and managed by the CMS.

The FDI incorporates a digital backbone based on two data centres where all the shared computing power is concentrated, one of which located inside the PSIM module while the other is under the hangar area for redundancy and higher platform’s survivability. This digital backbone with a highly-capable, user-friendly, cyber-defence software-based management capability (CyMS) for both the platform and combat systems is also used for obtaining usage and diagnostic information, enhancing maintenance and logistic support in favour of reduced life cycle costs. The FDI also incorporates for the first time on a French Navy ship a new ‘digital warfare centre’ located behind the platform conduction and navigation bridge, capable to manage around-platform surveillance and inner-layer protection. Although characterized by high automation, the FDI’s crew level stands at 125 elements, including the 14-elements flight detachment (as for the FREMMs crew), while the total accommodations allow for a 150-elements, the difference represented by naval infantry for inspection and protection activities and /or special forces operator detachments or other mission-oriented personnel. Naval Group and the French Navy paid particular attention to the comfort of the crew and rest time.

In addition to the antennas (except primarily for the Syracuse military SATCOM antenna positioned in front of the integrated mast) of the Thales Aquilon communications suite embodying SATCOM, Data Link 11, 16 and 22, the PSIM includes the aforementioned Thales Sea Fire multifunction radar, the new generation phased-array Thales BlueGate IFF combined interrogator/transponder (Mode 5/S), the 360° electro-optical and infrared package, and the EW suite. The EO package supplied by Bertin Technologies provides a 360° 4K day/low-light panoramic camera coverage around the ship to the asymmetric warfare centre, also served by the two Safran new-generation Paseo XLR long-range system turrets ensuring the 360° surveillance, identification and tracking in the IR band in support of the two 20 mm remotely operated cannons. The Thales new-generation EW suite features the digital wide-band Sentinel radar-band electronic support measures (RESM) and the Altesse-H communications ESM (CESM) system, controlled by an EW management unit. The FDI will be fitted-for accommodating a COMINT suite, when the assigned mission will require. The new-generation EW suite is planned to grow as both the platform and the suite are fitted for accommodating next-generation passive and active defensive systems as part of a ‘Stage 2’ or follow-on programme phases. The French Navy is investigating and evaluating under a separate programme which technologies and systems could be added in the future, looking to jammers, decoy launchers, passive and active expandable decoys. The sensors suite also includes the Thales Nederland STING EO Mk2 radar/EO fire control system for the main gun mount. The navigation component is centred on an iXblue suite including Marins inertial navigation systems and Netans navigation data distribution & processing units in addition to two navigation and a helicopter control radar.

The underwater sensors and effectors package feature the Thales-provided Kingklip Mk2 hull-mounted and CAPTAS 4 Compact low-frequency active/passive variable-depth sonar (VDS), the Naval Group Contralto anti-torpedo reaction system with two Canto decoy-launchers positioned on both sides over the hangar area superstructures, and two twin-tube launchers for MU90 lightweight torpedoes (LWTs). The ship can also embark an NH Industries NH90 Caiman ASuW/ASW helicopter equipped with the Thales Flash dipping sonar, sonobuoys and MU90 LWTs. As a novelty for the FDI platform, all sonar data are managed by the Thales-developed BlueScan federated integrated underwater warfare system, which processes the multi-platform, multi-sources contact information to provide fused sub-surface tracks into the CMS. The BlueScan’s embedded functionalities include automatic torpedo alert, multi-sonar performance optimisation, classification support and acoustic track management.

The FDI’s armament package is centred on a Leonardo 76/62 mm Super Rapido medium main gun, the new MBDA’s Aster family-based air defence missile system including the multipurpose vertical launching system with two-eight cell Naval Group Sylver A50 VLS for Aster 15/30 missiles positioned, both positioned in the bow area, and two-four canisters groups for a total of eight MBDA MM40 Block 3/Block 3c Exocet anti-ship missiles (ASMs) amidship. MBDA has been contracted to develop a new generation of firing installation named Installations de Tir Reconfigurables (ITR) for the French Navy, which will find application for the first time on the FDI, to operate all the (MBDA) missile weapon systems on board, in the specific case for the ASuW (Exocet) and AAW (Aster) missions. Close-in protection is offered by two remotely-controlled Nexter Narwhal 20 mm guns, respectively positioned on the hangar starboard side and main navigation bridge port sponson, and two-twin tube launchers for MU90 Murene lightweight torpedoes. The FDI’s combat system also controls two non-lethal weapon-equipped system turrets provided by Exavision with acoustic and optical effectors. The FDI/Belh@arra platform has been designed to accommodate in the bow area two additional Sylver family’s 8-cell VLSs for a total of 32 cells including the longer A70 model for additional missiles, other payloads and the Missile De Croisière Naval (MdCN) cruise missile system, which is however at this stage not part of the French Navy’s FDI weapon suite.

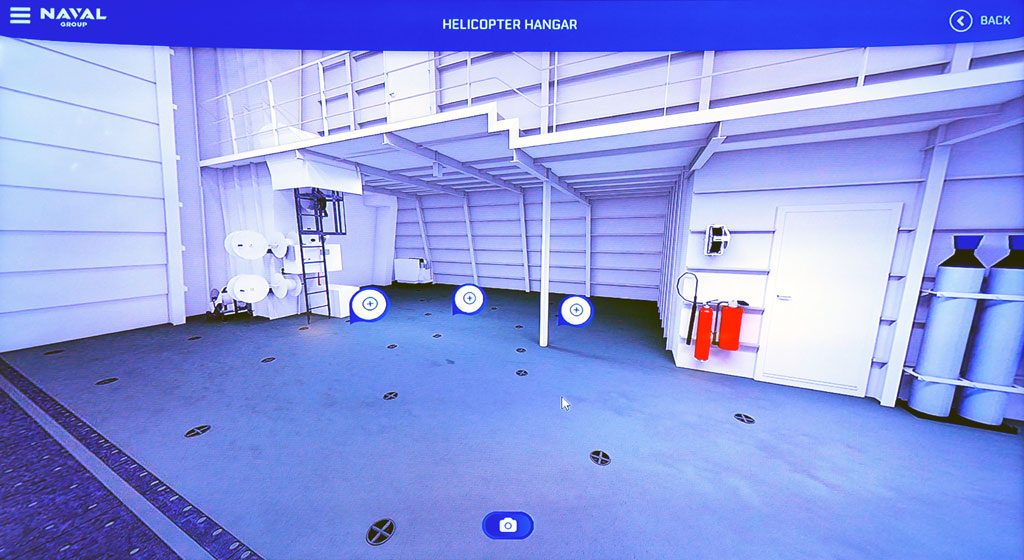

The FDI also features an 11 tonnes helicopter flight deck and hangar to accommodate an NHIndustries NH90 Caiman helicopter and a 700 kg Vertical Take-Off UAS with multi-payload capability in a dedicated space in the hangar alongside the piloted rotary-wing platform. Although the NH90 Caiman will provide a full ASuW/ASW, the future French Naval Aviation organic rotary-wing asset which will find accommodation on board the FDI frigates will be the Guépard Marine, a naval version development of the joint armed forces’ Hélicoptère Interarmées Léger (HIL) programme based on the Airbus Helicopters H160 platform, which will be armed with the MBDA ANL/Sea Venom anti-surface new generation missile. The VTUAV is under development by Airbus Helicopters and Naval Group together with Hélicoptères Guimbal, within the DGA’s SDAM (Système de Drone Aérien Marine) programme for the French Navy, based on the VSR700 platform. The strong special forces’ ship capability requirement has been satisfied with boat recesses port and starboard forward of the hangar area for French Navy’s Commando 9.5 meters ECUME boats and smaller craft.

Photos courtesy Naval Group and by Luca Peruzzi