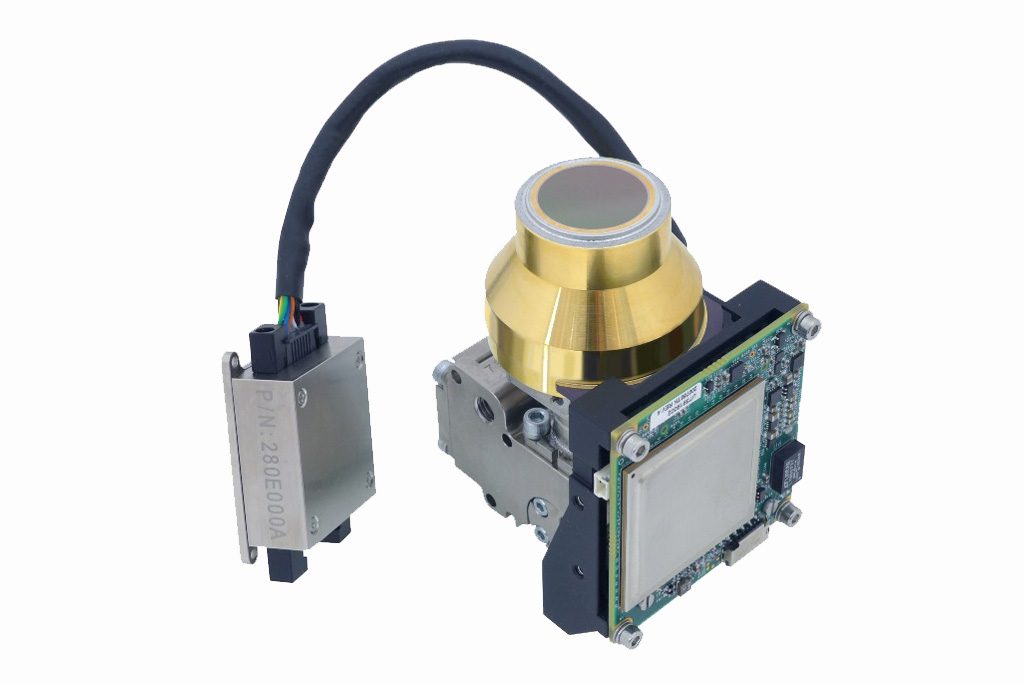

SCD introduces its Crane 5 µm pitch 5 megapixel MWIR detector

Thermal imaging has become a standard presence on the battlefield, and many improvements have been done in the past, however there is still more to do before reaching the physical limit of sensors, one of these being the pixel dimensions, which cannot be smaller than the wavelength considered for that frequency band.

Semi Conductor Devices of Israel, SCD in short, is specialised in high-end infrared detectors and laser diodes. At Eurosatory it unveiled a new Medium Wavelength InfraRed (MWIR) sensor, the Crane.“It is the first 5 µm pitch 5 megapixel detector in the MWIR band,” Kobi Zaushnizer, SCD VP Business & Marketing, tells EDR On-Line, adding that “it is the same achievement that was obtained by the big companies working in the visual segment when they reached the less than 1 µm pitch in the VIS band,” the latter going from 0.38 to 0.750 µm. As the MWIR band goes between 3 and 5 µm, the SCD detector is at the high end of the band. Asked if this is the last frontier in reducing the pitch, Mr. Zaushnizer said that “there is a debate among the scientific community about going down to 3 µm, but quite probably we reached the physical limit.”

The Crane has a 2560 x 2048 pixel matrix, has a maximum frame rate of 60 Hz at full frame, weighs 360 grams (the previous 10 µm detector weight was around 800 grams), and has a total power consumption of 7 W, 4 of which due to the rotary cooler (compared to the 9 W of a standard VGA resolution detector).

Reducing so much the pixel size brings with it some problematic, as there are two factors that influence the performances of the detector. “The first is how to preserve the quantum efficiency of the material, and the second is how to avoid cross-stock between pixels in order not to have a blurry image, he explains. Another thing that must be taken into consideration is that in MWIR detectors there are two chips in every Focal Plane Array (FPA), which is not true in CMOS used in the VIS spectrum. “We have the sensing materiel, the XPM, where the photodiodes of the 5 µm pitch are located, and beneath them we have the read out integrated circuit, ROIC in short, flip-chip bonded to the sensing material, and when reducing dimensions the latter process becomes very challenging,” Mr. Zaushnizer explains, adding that the size reduction risk to impact cross-stock, noise, and overall performances. “The breakthrough we achieved is to develop of a unique flip-chip bonding process that allowed us to go down to 5 µm, secondly we also developed a unique photolithographic capability and process that enable us to preserve both the cross-stock and quantum efficiency comparable to those we have in 10 µm pitch sensors.” Continuing to depict the production process of the new detector, and the progress made by SCD in production processes, the company VP Business & Marketing adds, “A second achievement concerns the ROIC itself, as when reducing size we have less of what we call ‘real estate’, to do all the logic of the readout circuit. We jumped from the current technology, used in the industry for IR detectors, which is usually 180 nm CMOS technology, to a proprietary technology allowing to reach much less than 90 nm, and this enables us to squeeze the capabilities into the ROIC.”

The Crane is fully ready and already started integration with several OEMs worldwide according to SCD, and in early June the company moved to full rate production for its latest MWIR detector. The SWAP operation carried out by SCD allows widening the MWIR market to tactical forces, to small UAS, another area being that of C-UAS systems, a domain where very high resolution is definitely of interest as it allows to detect, recognise and identify the threat at much longer ranges compared to today 1 MP detectors.

“Having a 5 MP detector, this first of all allows to avoid having a very complex and expensive zoom optics, as it i sufficient to have a much more simple optics, one or two fields of view, doing all the rest using digital zooming as the new detector will provide sufficient resolution to do it, and this is a considerable added value. Another advantage is that the operator can see on its screen only one portion of the area covered, the machine working on the other areas tracking and identifying targets, and automatically moving the picture onto the area of interest, so there is considerable room for AI application when working on such high resolution sensors, and we are opening to OEMs the opportunity to benefit from the 5 MP resolutions, in order to enhance the performances of their systems.” The system can thus be based on a lens providing a wide field of view, which makes surveillance much easier, and then zoom in once a target has been identified, not needing long zooms or telephoto lenses also helping on the stabilisation side.

Exploiting the reduction in pitch to further increase the number of pixels brings to a series of considerations. “The first one is due to technology limits, because enlarging the dye of the FPA manufacturing becomes much more challenging, because the yield of the semiconductor becomes very challenging, and this is why the semiconductor industry is pushing towards smaller arrays.” Other issues are the lens dimensions, to ensure appropriate optical coverage of the matrix, as well as cooling. “We consider that our 5 µm pitch 5 megapixel detector is a sort of a sweet spot, as it is small while providing a high resolution. I will not however be surprised if in around 5 years time we will come up with a 12 MP detector with the same technology, which might open up also space applications,” Kobi Zaushnizer concludes.

Photos courtesy SCD